Self priming centrifugal diesel engine four wheel trailer pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

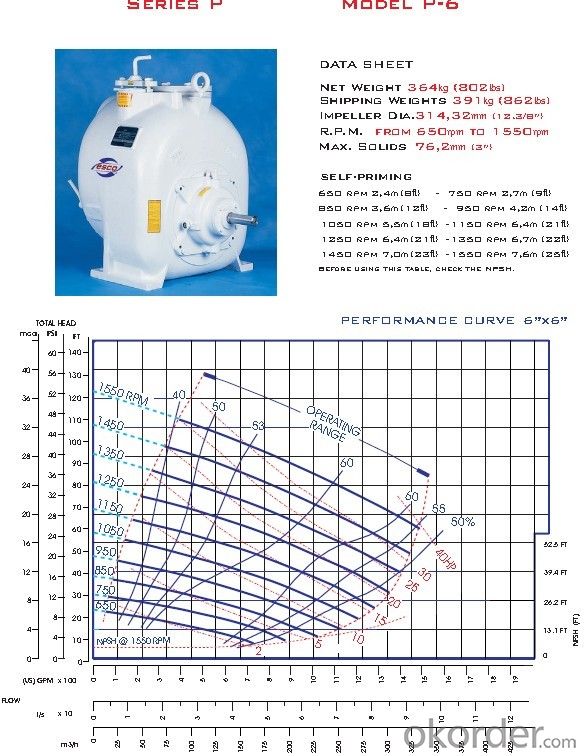

Main datas:

Capacity( flow rate) :35 ~ 310m3/h

Head :5~58 m

Speed:850 ~ 1950rpm

Impeller diameter:317.5mm

Pump weight:413kg /437kg

Power:5 ~ 75 hp

Advantage :

Big pump body pass 31.75mm solid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME: Self priming centrifugal diesel engine four wheel trailer pump

Standard Self-Priming pump units are available for Solids Handling or Clear Liquid service. Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

4)Parameter

| 1.Inlet/Outlet | 2''(50mm), 3''(75mm), 4''(100mm), 6''(150mm), 8''(200mm), 10''(250mm), 12''(300mm) | |

| 2.Impeller Diameter | 158.74mm-457.2mm | |

| 3.Rotary Speed | 550RPM-2150 RPM | |

| 4.Flow Rates | 8m3/h-1275m3/h | 20GPM-5500GPM |

| 5.Head | 6m-63m | |

| 6.Horsepower | 1HP-125HP | |

| 7.N.W | 92KG-998KG | |

| 8.G.W | 114KG-1066KG | |

| 9.Solid Passing | 20.63mm-76.2mm | |

| 10.Material | Cast Iron, ADI, CD4MCU, 316 SS, Alloy 20, C276. | |

| 11.Diesel Driving | Water cooled or air cooled | |

| 12.Method of Connection | Self-priming pumps are available as basic units or may be flex-coupled, V-belt driven or engine mounted. | |

| 13.Drive Variation | Cummins, Deutz, Ricardo, Perkins or Chinese Diesel, Electric Motor | |

| 14.Skid Mounted on Trailer | 2 or 4 wheels Trailer/Trailor,Cart | |

| 15.Package | Exporting plywood case | |

| 16.Certification | CE , ISO9001:2008 ,TUV | |

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Prameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q: The distance from the pump button to the ground

- A button is arranged on the surface of the fire hydrant button, and when the fire hydrant is started, the press button can be pressed directly, and the red starting indicator light of the fire hydrant button is on

- Q: How to install, operate and maintain the pipeline booster pump?

- The motor coil is provided with a safety protector, and when the pump is out of order or the water is not pumped, the motor can automatically break down when the temperature of the motor exceeds the prescribed value, and the motor can automatically resume operation after the temperature rise of the motor is decreased. The booster pump motor is a capacitor running type motor. When the pump leaves the factory, the rotation direction has been adjusted. If you need to replace the capacitor or re connect, press the arrow direction on the pump body to mark the connection. To ensure safety, use the three - core safety socket with ground wire.

- Q: Concrete pump 125 pipe wall thickness

- Concrete pump, also called concrete pump, consists of pump body and pipe. The utility model relates to a machine for continuously conveying concrete along a pipeline by utilizing pressure, which is mainly used for building, bridges and tunnels

- Q: What is the pumping property of concrete?

- Pumpable concrete slump is generally greater than 160mm, the mortar content is too low, the maximum aggregate size of not more than 1/3 of the diameter of the pump pipe, sending process segregation, plugging in the pump.

- Q: Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- Direct connected pump: pump impeller installed directly on the motor shaft, it looks like a whole, relatively compact, simple installation, but the general power is relatively small (big bad processing connection, but not absolute);Non direct pump: pumps and motors are independent of each other, through the coupling torque transmission, the structure is relatively large, complex installation, to adjust the level / concentricity and so on, the general power is relatively large

- Q: Is vane pump good or gear pump good?

- The main parts of a gear pump are gears that mesh with each other. The meshing driving gear and the driven gear are respectively arranged on two parallel rotating shafts. Because the gear teeth enter and exit the meshes, the volume of the teeth is changed, and the suction and discharge effect is formed.

- Q: Common failure treatment of piston pump

- 1) overflow valve regulation is too high, overload after the pump2) the overflow valve spool is blocked, the central hole of the valve core is blocked or the overflow valve is blocked by a damping hole, and the overflow is not overflow3) pump outlet one-way valve installed or spool blocked and stuffy pump4) motor fault x091) adjust the relief valve pressure value2) repair valve boring3) overhaul check valve4) overhaul or replace the motor

- Q: How many concrete pump tube diameter

- The pump is generally divided into 125 and 150 two, the inner diameter is 125mm and 150mm. And the two kinds of each have high and low pressure points. Low pressure type type 125 pump for the pipeline diameter is phi 133,

- Q: What is an industrial water pump?

- Industrial water pump, water pump for industrial production.A pump is a machine that transports liquids or pumps liquids. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- But the reverse cleaning can not completely regenerate the filter medium, or there will be some impurities remain, when the regeneration of residual impurities (pressure drop) to set the value, you need to replace the filter (filter media).

Send your message to us

Self priming centrifugal diesel engine four wheel trailer pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches