Self priming 8 inch Centrifugal sewage electric motor pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

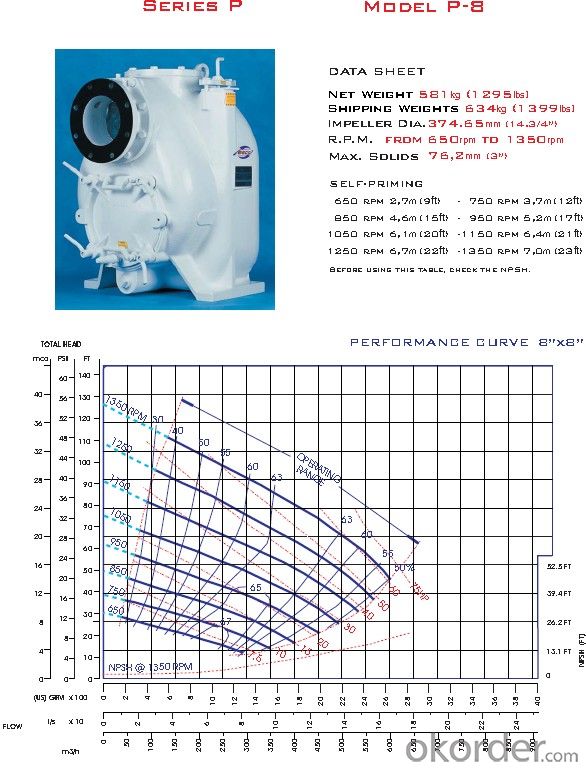

Main datas:

Capacity( flow rate) : 40-600 m3/h

Head :4-34 m

Speed:650 ~ 1500 rpm

Impeller diameter:375 mm

Pump weight: 581 kg / 634 kg

Power: 7.5 ~ 75 hp

Advantage :

Big pump body pass 31.75mm solid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME:Self priming 8 inch Centrifugal sewage electric motor pump

Standard Self-Priming pump units are available for Solids Handling or Clear Liquid service. Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

4)Parameter

| 1.Inlet/Outlet | 2''(50mm), 3''(75mm), 4''(100mm), 6''(150mm), 8''(200mm), 10''(250mm), 12''(300mm) | |

| 2.Impeller Diameter | 158.74mm-457.2mm | |

| 3.Rotary Speed | 550RPM-2150 RPM | |

| 4.Flow Rates | 8m3/h-1275m3/h | 20GPM-5500GPM |

| 5.Head | 6m-63m | |

| 6.Horsepower | 1HP-125HP | |

| 7.N.W | 92KG-998KG | |

| 8.G.W | 114KG-1066KG | |

| 9.Solid Passing | 20.63mm-76.2mm | |

| 10.Material | Cast Iron, ADI, CD4MCU, 316 SS, Alloy 20, C276. | |

| 11.Diesel Driving | Water cooled or air cooled | |

| 12.Method of Connection | Self-priming pumps are available as basic units or may be flex-coupled, V-belt driven or engine mounted. | |

| 13.Drive Variation | Cummins, Deutz, Ricardo, Perkins or Chinese Diesel, Electric Motor | |

| 14.Skid Mounted on Trailer | 2 or 4 wheels Trailer/Trailor,Cart | |

| 15.Package | Exporting plywood case | |

| 16.Certification | CE , ISO9001:2008 ,TUV | |

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Prameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

Components Display

- Q: Fire hydrant pump button, under what circumstances do not need to install?

- The installation of hydrant pump buttons depends on the type of water supply:(1) municipal water supply; (in this case, do not have to install)(2) there is a fire pump; (must be installed)

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- For the first time, the pump and motor were placed on the base and not fastened (Cu Zhaozheng);Second times, the pump and motor have been tightened, the inlet and outlet flange bolts are not fastened;Third times, the pump runs 24 hours later.

- Q: If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- The role of the check valve:"[the water pump impeller is not closed" refers to the pump suction pump before the water without water inlet pipe and water outlet pipe gas should be connected] is a connector, a connector, still can make the level surface, in order to prevent the water flow along the pipe, until it reaches the level of the flush, then increased check valve, or pumping up water will not leak?Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".....

- Q: What should I pay attention to when buying a pump?

- Four, packing inspection1. with the pump supply documents shall include: product certification, specification, packing list, agricultural pumps (such as submersible pumps, centrifugal pumps, mixed flow pumps, self-priming pump etc.) should be "Three Guarantees certificate", the implementation of the production permit (such as pump submersible pump, high pressure pump, high temperature pump 5 pump) we should have a production license.2. plugging of the orifice, to withstand wind and rain invasion, and should be strong, can withstand accidental damage.3. pumps and all supplied bulk parts supplied with the pump shall have the required identification number and shall be clear.4. pairs of oil lubricated bearings, bearings tank oil should be discharged, and fixed with "need oil filling" warning signs.

- Q: There are 6 pumps, two indoor fire hydrant pumps, two spray pumps, two outdoor pumps, three units, one master and one spare control cabinet. From the control room to the control cabinet, is there only 3 lines or 9 lines?... How do I get it? Where does the hydrant line come from?

- Indoor fire hydrant pump in addition to remote direct Kai, there are modules to start function, that is, on the cabinet to add control module, bus linkage pump, but also fire hydrant button, direct pumping function, a total of three functions.Outdoor fire hydrant pump in addition to remote direct Kai, but also an electric contact pressure meter detection system, water pressure from the pump and high pressure pump stop function.

- Q: The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- Difference:The installation position is different: one can discharge water, one is on the ground.The work principle is different: the principle of submersible pump is similar to the electric fan, centrifugal pump through centrifugal force to make the water throw out. According to the principle of centrifugal force design,

- Q: Fire control center manually start the fire pump directly, multi line control, called straight up line NHKVV-7*1.5, my understanding is: straight line from fire control center

- Multi line linkage NHBVR-4*1.5 is a positive pressure blower and smoke exhaust machine fire fighting equipment

- Q: Why should I pump the pump before starting the centrifugal pump?

- Before the operation of the centrifugal pump, the pump must be filled with water, exhaust the air, before you start the operation. All centrifugal pumps should be handled this way, which is the centrifugal pump itself.The way of water diversion:1., in the centrifugal pump outlet increase water diversion pump (usually using vacuum pump), start the centrifugal pump before, start the vacuum pump, the centrifugal pump air into;2. increase the vacuum water tank before the intake of the centrifugal pump to meet the working conditions of the centrifugal pump;3. in the centrifugal pump inlet water increase valve, to meet the working conditions of centrifugal pump;4., if the water tank or water tank volume of water level is higher than the centrifugal pump position, the first operation of the front row empty, usually do not empty, you can use.

- Q: What is the function of the heating pump system for the water pump design?

- Will cause some of the internal friction gap disappeared, the coupling center damage. In this case, starting the pump inevitably results in vibration, friction, etc.

- Q: I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- Specification for concrete cylinders:Bore * stroke mm 200 * 1650Hopper capacity L 800Feeding height mm 1400Motor model Y2-280M-4Power kw 90Rated voltage V 380Rated speed r/min 1480Soft starter withoutHydraulic system open-loop

Send your message to us

Self priming 8 inch Centrifugal sewage electric motor pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords