Self priming 6 inch diesel water pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

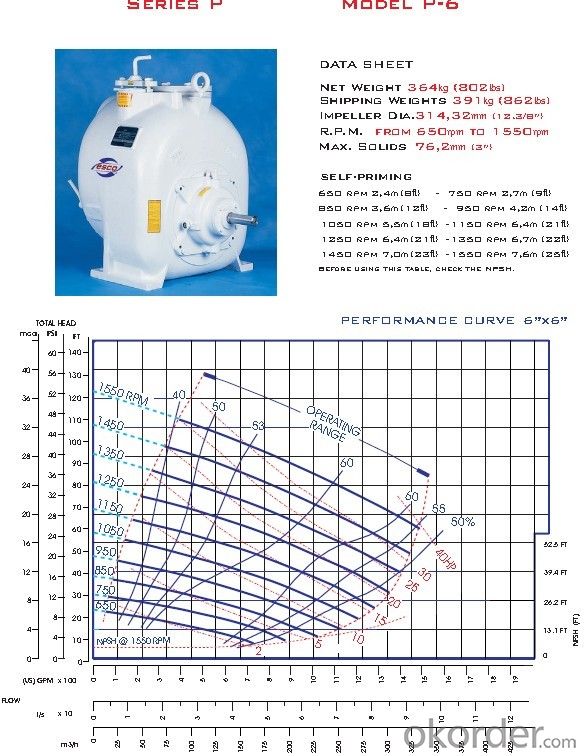

Main datas:

Capacity( flow rate) :35 ~ 310m3/h

Head :5~58 m

Speed:850 ~ 1950rpm

Impeller diameter:317.5mm

Pump weight:413kg /437kg

Power:5 ~ 75 hp

Advantage :

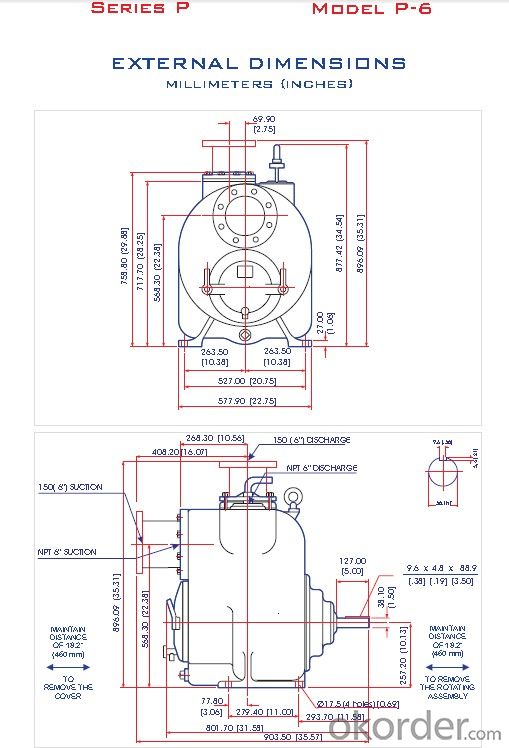

Big pump body pass 31.75mm solid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME: 6 inch diesel water pump

Standard Self-Priming pump units are available for Solids Handling or Clear Liquid service. Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

4)Parameter

| 1.Inlet/Outlet | 2''(50mm), 3''(75mm), 4''(100mm), 6''(150mm), 8''(200mm), 10''(250mm), 12''(300mm) | |

| 2.Impeller Diameter | 158.74mm-457.2mm | |

| 3.Rotary Speed | 550RPM-2150 RPM | |

| 4.Flow Rates | 8m3/h-1275m3/h | 20GPM-5500GPM |

| 5.Head | 6m-63m | |

| 6.Horsepower | 1HP-125HP | |

| 7.N.W | 92KG-998KG | |

| 8.G.W | 114KG-1066KG | |

| 9.Solid Passing | 20.63mm-76.2mm | |

| 10.Material | Cast Iron, ADI, CD4MCU, 316 SS, Alloy 20, C276. | |

| 11.Diesel Driving | Water cooled or air cooled | |

| 12.Method of Connection | Self-priming pumps are available as basic units or may be flex-coupled, V-belt driven or engine mounted. | |

| 13.Drive Variation | Cummins, Deutz, Ricardo, Perkins or Chinese Diesel, Electric Motor | |

| 14.Skid Mounted on Trailer | 2 or 4 wheels Trailer/Trailor,Cart | |

| 15.Package | Exporting plywood case | |

| 16.Certification | CE , ISO9001:2008 ,TUV | |

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Prameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q: Why does the centrifugal pump close the pressure to start?

- The flow is zero (i.e. off dead) minimum, the highest lift power; with the outlet valve opening increases, flow increases, the lift, power and efficiency are increased, the maximum value (usually in the vicinity of the highest rated flow point)

- Q: Working principle and diagram of axial piston pump with pressure compensation variable

- Adjust the flow characteristics, the first limit screw to the top, according to the flow and pressure changes in the required range, adjusting the spring set, the initial flow pressure began to change to meet the requirements, then the limit screw to the ultimate pressure when the flow is no longer changed, the relationship between flow and pressure the changes are determined by the pump itself.

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- (1) pump connected outside pipes, containers, pipes, joints and other leakage test instrument, large leakage, rotary gas plug exhaust sound big, and the gas and oil mist discharge, should find leakage cancellation.(2) the assembly of rubber of intake pipe is not proper, damage or aging should be adjusted or replaced.(3) plug hole, the vacuum degree can be decreased, put the oil, remove the tank, loosen the nozzle plate, pull out the oil inlet nozzle, dredge oil hole, try not to use cotton wipe parts.(4) the vacuum system has serious pollution, including containers, pipes and so on. It should be cleaned.(5) the spring of the vane is broken and should be adjusted.

- Q: What are the causes of pump shock?

- Troubleshooting cause1. bearing damage, replace new bearings2., coupling pin, bolt damage, rubber column or metal bolt wear, change

- Q: How to distinguish the flow and displacement in the hydraulic pump? What's the difference between the two?

- If you're allowed to spend a minute, you can do it 20 times a minute, and that is, the amount of water you sprinkle at a time (1000) is *20.1000 (ML) *20=20000 ml =20 liters, this is the flow,Here is a formula for you to see,Pump displacement * pump speed = flow,

- Q: Excuse me, what is the water pump from the lotus root?

- Submersible sewage pump with septic tank, outlet pipe automatic coupling installation, dipping down can be.

- Q: How many kilograms of water pump are there in the automatic washing machine on the market?

- High pressure pump pressure can reach 4--8kg, flow 5 liters, work current 4 or so.

- Q: What are the conditions required for hydraulic pumps to complete oil absorption and compression?

- 2, the change of working volume is periodic, and in each cycle, the oil absorption process is changed from small to big, and the process of oil pressure is changed from large to small;3, suction oil cavity must be separated from each other without interference.

- Q: What is an industrial water pump?

- The pump has the different uses, conveying different liquid medium, different flow rate, different lift range, therefore, its structure of course is not the same, the material is different, in general, can be divided into:1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

- Q: Filter backwash pump for what use, what is the principle of work ah?

- Regeneration of the filter medium is required to regain the filtration capacity of the medium. The regeneration process is mainly accomplished by the backwashing pump (the backwash pump is not a special pump, referring to the pump for the completion of the process). The working principle is through the cleaning liquid from the downstream of the filter into the backwash pump (alkali, acid and water), reverse flushing filter medium, cleaning liquid discharged from the upstream, this process can be attached to the dielectric surface and internal impurities washed away.

Send your message to us

Self priming 6 inch diesel water pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords