Self-adhesion rubber asphalt waterproofing membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

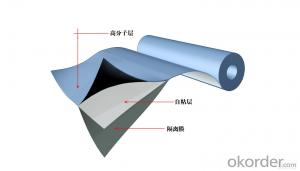

1.Structure of Self-adhesion rubber asphalt waterproofing membrane Description:

Self-adhesion rubber asphalt waterproofing membrane is based on SBS elastomer and asphalt base makings, to polyethylene film, aluminum foil as the surface material or film (double-sided adhesive), adopting the anti-sticking layer of self-adhesive waterproof material. Since the sticky rubber asphalt waterproof coiled material is a kind of have broad prospects for development of new building waterproof material, has excellent waterproofness, low temperature flexibility and extensibility, caking. Especially it has self-healing, this is generally do not have the advantages of waterproof material, can ensure the quality of waterproof engineering super waterproof.

2.Main Features of Self-adhesion rubber asphalt waterproofing membrane:

The elasticity of rubber, excellent elongation.

Excellent sticky relay at the base

Construction safety, no pollution and easy construction

A self-healing, corrosion resistance.

3.Self-adhesion rubber asphalt waterproofing membrane Specification:

| P | PY | |||

| Tensile Strength(N/5mm) | 500 | 800 | ||

| Tear strength/N | 400 | 200 | ||

| Elongation at break,% | 400 | - | ||

| Flexibilty at low temperature | -25℃,No crack |

4.Self-adhesion rubber asphalt waterproofing membrane Images:

- Q: Are there any specific installation requirements for waterproofing membranes?

- Yes, there are specific installation requirements for waterproofing membranes. These requirements may vary depending on the type of membrane being used, but there are some general guidelines that apply to most installations. Firstly, it is important to properly prepare the surface that the membrane will be applied to. This may involve cleaning the surface, removing any loose debris or previous coatings, and ensuring the surface is smooth and free from any irregularities. This step is crucial as it allows for better adhesion between the membrane and the surface. Next, the membrane should be applied according to the manufacturer's instructions. This typically involves using a suitable adhesive or bonding agent to adhere the membrane to the surface. It is important to follow the recommended application rate and ensure that the membrane is applied evenly and without any air bubbles or wrinkles. In addition to proper application, it is also important to pay attention to the seams and joints of the membrane. These areas are particularly vulnerable to water penetration, so they should be carefully sealed using an appropriate sealant or tape. This ensures a watertight seal and prevents any water from seeping through the seams. Lastly, it is important to protect the installed membrane from any damage during and after installation. This may involve covering the membrane with a protective layer, such as a geotextile fabric or a layer of soil, to prevent punctures or tears. Additionally, any construction or landscaping work that may occur after the installation should be done with caution to avoid damaging the membrane. Overall, the specific installation requirements for waterproofing membranes will depend on the type of membrane being used and the specific conditions of the project. It is always recommended to consult the manufacturer's instructions and guidelines to ensure proper installation and long-lasting waterproofing performance.

- Q: Can a waterproofing membrane be applied to roofing systems?

- Roofing systems can benefit from the application of a waterproofing membrane. Such membranes are commonly utilized in roofing to add an extra layer of defense against water and moisture infiltration. These membranes are typically composed of synthetic materials like PVC or EPDM and are crafted to be durable, flexible, and resistant to environmental influences such as UV radiation and temperature changes. When installed correctly, a waterproofing membrane can effectively prevent leaks, prolong the lifespan of the roof, and safeguard the underlying structure from water damage. It is crucial to seek guidance from a professional roofing contractor to identify the most suitable type of waterproofing membrane for a specific roofing system and to ensure proper installation and maintenance.

- Q: Can a waterproofing membrane be used on precast plastic surfaces?

- Yes, a waterproofing membrane can be used on precast plastic surfaces. These membranes are designed to be versatile and can be applied to a variety of materials, including plastic. They provide an effective barrier against water penetration and help protect the underlying surface from moisture damage.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Yes, a waterproofing membrane can be used on tunnels with fire protection systems. The waterproofing membrane is designed to provide protection against water ingress, while the fire protection system is designed to prevent or minimize the spread of fire. These two systems can be installed and utilized together to ensure the safety and integrity of the tunnel infrastructure.

- Q: Can a waterproofing membrane be used for mechanical rooms?

- Yes, a waterproofing membrane can be used for mechanical rooms. Mechanical rooms often house various equipment and systems that require protection from water damage. Waterproofing membranes provide a barrier against water intrusion, preventing moisture from penetrating the structure and potentially causing damage to the mechanical equipment. By applying a waterproofing membrane to the walls, floors, and even ceilings of a mechanical room, it helps to ensure a watertight environment that prolongs the lifespan of the equipment and reduces the risk of water-related issues. Additionally, waterproofing membranes can also provide protection against other forms of moisture, such as condensation or high humidity levels, which can be detrimental to the functionality of mechanical systems. Overall, using a waterproofing membrane in mechanical rooms is a sensible and effective measure to safeguard the equipment and maintain a dry and functional environment.

- Q: Can a waterproofing membrane be used on tunnels with seismic protection systems?

- Yes, a waterproofing membrane can be used on tunnels with seismic protection systems. In fact, it is highly recommended to use a waterproofing membrane in such tunnels to prevent water ingress and subsequent damage to the structure. Seismic protection systems are designed to absorb and dissipate the energy generated by an earthquake, ensuring the safety and stability of the tunnel. However, these systems do not provide any protection against water infiltration. By installing a waterproofing membrane, the tunnel can be safeguarded against potential water leaks and seepage, which can lead to corrosion of reinforcement, deterioration of concrete, and overall structural damage. It is important to select a waterproofing membrane specifically designed for use in tunnels, considering factors such as flexibility, durability, and resistance to movement caused by seismic events. Additionally, proper detailing and installation techniques should be employed to ensure a seamless and effective waterproofing system that works in conjunction with the tunnel's seismic protection measures.

- Q: Can a waterproofing membrane be used for zoos or aquariums?

- Yes, a waterproofing membrane can be used for zoos or aquariums. Waterproofing membranes are designed to prevent water penetration and provide a watertight barrier, making them suitable for use in areas that require high levels of water resistance such as zoos or aquariums where water containment is critical.

- Q: Can a waterproofing membrane be used for water fountains or decorative features?

- Yes, a waterproofing membrane can be used for water fountains or decorative features. Waterproofing membranes are designed to provide a protective barrier against water penetration and can be applied to various surfaces, including those used in water fountains and decorative features. These membranes are typically made from materials such as rubber, bitumen, or liquid-applied coatings, which offer excellent waterproofing properties. By applying a waterproofing membrane, you can ensure that water does not seep into the underlying structure and cause damage. This is particularly important for water fountains and decorative features as they involve constant exposure to water. Additionally, waterproofing membranes can also help prevent leaks, cracks, and other potential issues that may arise from water exposure, thus prolonging the lifespan of the fountain or decorative feature.

- Q: Are waterproofing membranes resistant to chemical solvents?

- Yes, waterproofing membranes are generally resistant to chemical solvents. They are designed to provide a barrier against water and other liquids, including chemical solvents, to prevent leakage and damage to the underlying structure.

- Q: Can a waterproofing membrane be used on elevator pits?

- Yes, a waterproofing membrane can be used on elevator pits. Elevator pits are vulnerable to water damage due to their location below ground level and the potential for water infiltration. Installing a waterproofing membrane in the elevator pit can help protect the structure from water damage and prevent issues such as corrosion, mold growth, and deterioration. The membrane acts as a barrier, preventing water from seeping into the pit and causing damage to the elevator equipment or the surrounding structure. It is important to select a waterproofing membrane specifically designed for below-grade applications and to ensure proper installation to achieve effective waterproofing in elevator pits.

Send your message to us

Self-adhesion rubber asphalt waterproofing membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords