Scaffolding Machine Formwork Scaffolding Hook CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Machine Formwork Scaffolding Hook CNBM

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

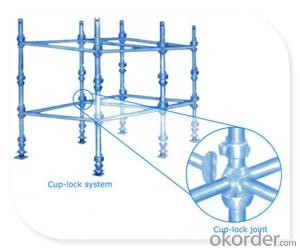

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

Scaffolding Machine Formwork Scaffolding Hook CNBM

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

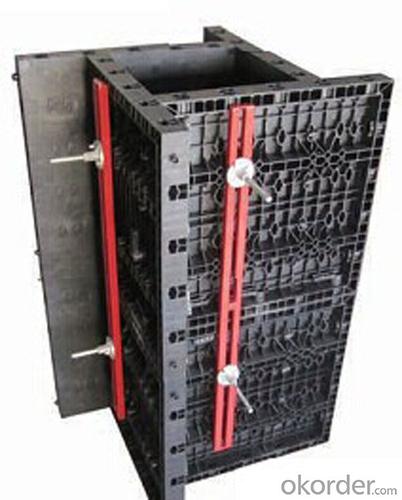

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

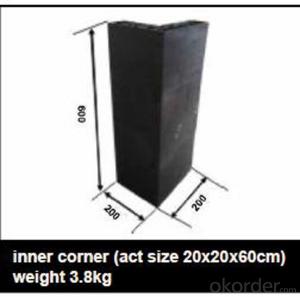

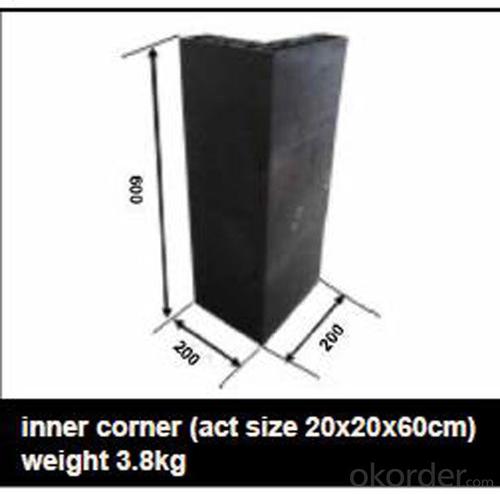

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

Scaffolding Machine Formwork Scaffolding Hook CNBM

- Q: Can steel frame formwork be used for both residential and commercial construction projects?

- Yes, steel frame formwork can be used for both residential and commercial construction projects. Steel frame formwork is a versatile and durable solution that can be used for various types of projects, including both residential and commercial buildings. It provides a high level of structural stability and can withstand heavy loads, making it suitable for large-scale construction projects such as commercial buildings. Additionally, steel frame formwork offers flexibility in terms of design and can be easily customized to meet the specific requirements of different projects, whether they are residential or commercial. Its strength and durability make it an ideal choice for both types of construction projects.

- Q: How is steel frame formwork dismantled after concrete curing?

- Steel frame formwork is typically dismantled after concrete curing by removing the formwork panels and props. The panels are carefully unclamped and lifted away from the concrete structure using cranes or other lifting equipment. The supporting props are then removed, ensuring the structure's stability is maintained throughout the process. This dismantling method allows for the easy and efficient removal of the steel frame formwork, leaving behind a solid and robust concrete structure.

- Q: Does steel frame formwork require any specific edge protection measures?

- Yes, steel frame formwork does require specific edge protection measures. These measures are necessary to ensure the safety of workers and prevent any potential accidents or falls from the edges of the formwork. Edge protection systems such as guardrails, toe boards, and safety nets should be installed to provide a safe working environment for construction personnel.

- Q: Can steel frame formwork be used in projects with limited construction site supervision or management?

- Steel frame formwork is a versatile and durable solution for creating concrete structures, making it suitable for projects with limited construction site supervision or management. Its robustness allows it to withstand heavy loads and extreme weather conditions, ensuring stability even without constant supervision. Moreover, the ease of assembly and disassembly of steel frame formwork facilitates quick installation and removal, reducing the need for skilled labor and speeding up the construction process. Additionally, its adjustability and customization capabilities enable construction teams to modify the formwork system without extensive supervision or guidance. Furthermore, the high reusability of steel frame formwork minimizes the need for constant supervision or management in terms of material procurement. This means that even with limited supervision on-site, the formwork system can be reused multiple times. However, it is important to note that proper installation and usage of steel frame formwork still require some level of expertise and knowledge. Therefore, it is advisable to have at least some level of supervision or management to ensure correct implementation. In conclusion, steel frame formwork is a suitable option for projects with limited construction site supervision or management. Its durability, ease of assembly, flexibility, and reusability make it a reliable choice. However, it is crucial to ensure that there is still some level of expertise or guidance to ensure proper installation and usage.

- Q: What are the transportation and storage requirements for steel frame formwork?

- The transportation and storage requirements for steel frame formwork are relatively straightforward. In terms of transportation, steel frame formwork is typically transported using trucks or trailers. Due to the weight of the steel frames, it is important to ensure that the vehicles used for transportation are capable of handling the load. The frames should be securely fastened to the vehicle to prevent any movement or damage during transit. As for storage, steel frame formwork should be stored in a dry and well-ventilated area to prevent rust or corrosion. Ideally, the frames should be stored indoors to protect them from the elements. If indoor storage is not possible, the frames should be covered with a waterproof tarp or sheeting to protect them from rain or snow. Additionally, it is important to stack the frames properly to avoid any deformation or damage. The frames should be stacked in a stable manner, with larger and heavier frames on the bottom and smaller frames on top. It is also recommended to place wooden spacers between the frames to prevent any direct contact and potential scratches. Regular maintenance and inspection of the steel frame formwork is also crucial to ensure its longevity and safety. This includes checking for any signs of damage, such as bent or cracked frames, and promptly addressing any issues that arise. Overall, proper transportation and storage of steel frame formwork is essential to protect the frames from damage and ensure their longevity, which in turn contributes to the efficiency and safety of construction projects.

- Q: Can steel frame formwork be used in projects with challenging ground conditions?

- Projects with challenging ground conditions can indeed make use of steel frame formwork. Renowned for its strength, durability, and stability, steel frame formwork proves suitable for construction projects where ground conditions may pose challenges or instability. The steel frame grants a sturdy structure, capable of withstanding the pressures and forces exerted by the ground, thereby ensuring the formwork system's safety and stability. Furthermore, steel frame formwork allows for easy adjustment and modification to accommodate various ground conditions, facilitating efficient and effective construction in demanding environments. All in all, steel frame formwork stands as a reliable and versatile solution applicable to projects confronted with challenging ground conditions.

- Q: What are the lead times for manufacturing steel frame formwork?

- The lead times for manufacturing steel frame formwork can vary depending on several factors. These factors include the complexity of the design, the quantity required, the availability of raw materials, and the current workload of the manufacturer. In general, smaller and less complex steel frame formwork orders can have lead times ranging from a few days to a couple of weeks. This is because these orders can usually be completed relatively quickly and do not require extensive fabrication processes. On the other hand, larger and more intricate steel frame formwork orders may have lead times of several weeks or even months. These orders often require more time for design, engineering, fabrication, and quality control processes. Additionally, if there is a high demand for steel frame formwork or if the manufacturer is experiencing a heavy workload, the lead times can be extended even further. It is important to note that lead times can also be influenced by external factors such as transportation delays, unforeseen production issues, or the need for customizations. Therefore, it is advisable to contact the manufacturer directly to get an accurate estimate of the lead time for a specific steel frame formwork order.

- Q: How does steel frame formwork handle the movement and settlement of a structure?

- The construction technique known as steel frame formwork utilizes steel frames to support the concrete during pouring and curing. One of the key advantages of this method is its capacity to handle the movement and settlement of a structure. Steel possesses a high level of tensile strength, which enables it to endure the forces caused by movement and settlement without deformation or failure. This quality is essential in construction due to the various types of movement and settlement that buildings undergo over time. First and foremost, steel frame formwork provides a rigid structure that evenly distributes the weight of the concrete across the foundation. This aids in minimizing any uneven settlement or movement that may arise. Furthermore, steel frame formwork is designed to be adaptable and flexible, allowing it to accommodate slight variations in the dimensions of the structure. This adaptability ensures that some movement can occur without compromising the integrity of the construction. This aspect is particularly crucial in regions with high levels of seismic activity, as it enables structures to withstand earthquakes and other ground movements. Moreover, steel frame formwork often features expansion joints, which enable the structure to expand and contract naturally without causing any damage. These joints play a vital role in areas with extreme temperature fluctuations, preventing the cracking of steel and concrete due to thermal expansion. In conclusion, steel frame formwork effectively manages the movement and settlement of a structure by providing a robust and flexible support system. Its high tensile strength, adaptability, and inclusion of expansion joints make it an ideal choice for withstanding the forces and movements that a building may encounter throughout its lifespan.

- Q: How does steel frame formwork affect the overall structural integrity of a building?

- The overall structural integrity of a building can be significantly impacted by the use of steel frame formwork. To begin with, steel frame formwork offers a robust and rigid support system for the concrete during construction. This guarantees the proper pouring and curing of the concrete, resulting in a structure that is more durable and sturdy. In addition, the use of steel frame formwork enables precise and accurate placement of the concrete, which is crucial for maintaining the building's structural integrity. The formwork system ensures that the concrete is poured in the correct location and shape, thereby preventing any potential weaknesses or irregularities in the structure. Furthermore, steel frame formwork provides exceptional stability and resistance against external forces like wind, earthquakes, and other loads. By acting as reinforcement, the steel framework enhances the overall strength and stability of the building. This is particularly important in areas that are susceptible to seismic activities or extreme weather conditions. Moreover, steel frame formwork exhibits high resistance to corrosion and deterioration, making it a reliable and long-lasting choice for construction. Its durability ensures that the formwork system does not compromise the structural integrity of the building over time. Overall, the utilization of steel frame formwork significantly enhances the structural integrity of a building. It offers a strong support system, precise concrete placement, stability against external forces, and long-term durability. Architects and engineers often prefer steel frame formwork due to its ability to guarantee a safe and sturdy structure, making it an indispensable component in the construction process.

- Q: How does steel frame formwork accommodate for electrical and plumbing installations within the concrete structure?

- Steel frame formwork accommodates for electrical and plumbing installations within the concrete structure by providing pre-determined openings and channels in the formwork panels. These openings and channels allow for the placement and routing of electrical and plumbing pipes, conduits, and fixtures before the concrete is poured. This ensures that the necessary infrastructure can be easily incorporated into the concrete structure without compromising its integrity.

Send your message to us

Scaffolding Machine Formwork Scaffolding Hook CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches