Cup Lock Scaffolding Cuplock System for Construction Formwork Building CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

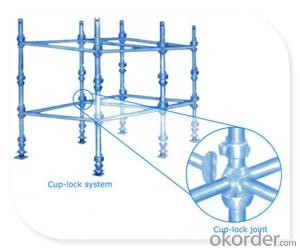

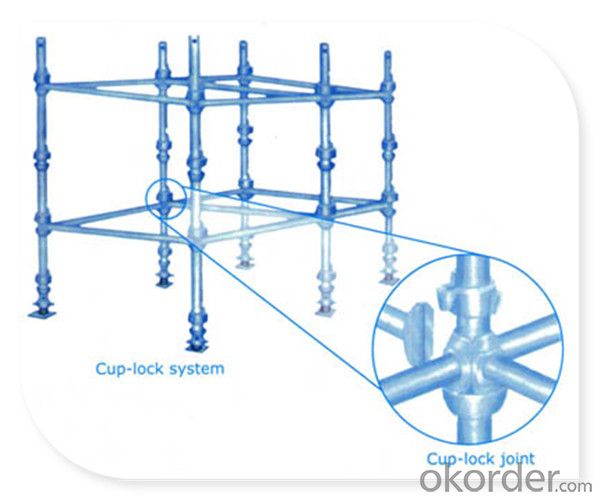

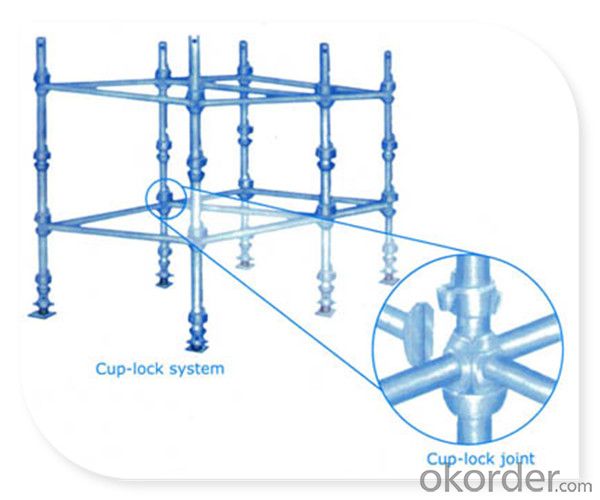

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

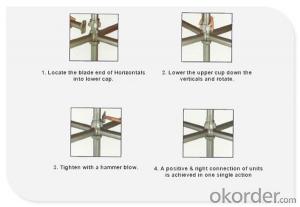

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Erection of steel scaffolding tools and safety supplies

- Anti falling device, professional tool bag, work boots (soft bottom shoes), safety lighting, transportation tools, pulley, skateboard rope, dustproof mask, special conjoined clothes, ear plugs

- Q: I have to write a 1 page commentary on a geographical issue for school, and, I've never done that before.Could someone please tell me or link me to a very simple 'writing commentary' scaffold for beginners?Please?Thankyou :)

- A vegan alcoholic! A chuckle emerges, a laugh perhaps for a few more bobs. Absent the mind, nicely put.

- Q: Where to use scaffolding in construction

- 5, the level should be closed: the first step, every step or two, covered with planks or hand foot fence, scaffolding to laying along the long, joints should be overlapped in the small bar, do not appear short board. And in between in the pole and the wall every four steps long laying safety bottom fence.6, vertical closure: from the second step to the fifth step, each step required in the outer row of pole side door set like baluster 1.00m high and block feet or to set up protective net, rod (net) and the vertical rod fastened; more than fifth steps in a protective railing, should all the safety fence or security legislation net; in the street or densely populated areas, should be from the second step, the safety fence or outside of all network security legislation.

- Q: According to the standard set up double scaffolding scaffolding to the number of meters per square meter

- The span, the rod step is easy to calculate, I have done the program in general 4.4.8 meters

- Q: i have some ?'s on the scarlett letterWhat effect has the 7=year interval had on Dimmesdale ?

- you can see how weak morally dimmesdale is, because he keeps his hand over his heart all the time, and is constantly beating himself up over his crime. he whips himself in the closet, and brands himself with a scarlett a to match hesters. hester... when she first walks out on the scaffold she can be seen as defiant, as if she isn't ashamed of the embellished letter a she wears. the cottage she lives in is on the edge of the town, bordering the forest. towards the end of the 7 years, her actions can be seen as repent maybe for her crime: she is a self ordained sister of mercy, helps the poor and homeless, sews... and the a turns from adultery to able

- Q: Right! I've heard from so many different people about this. Some say that you should never twist an industrial because it can damage the delicate newly healing skin cells. Others say that you must twist it to prevent the jewelry from healing attached to the skin and to be able to clean it properly.There really doesn't seem to be a definitive answer!My piercer has said not to twist it, so I haven't been, and I'm happy that the piercing is clean enough, etc. However I'm interested in whether any of you out there have found that not twisting it can damage it more than doing so.Thanks

- My piercer told me to move the bar up and down, not to twist it around. And now, it's a year and a few months later and I've never had any problems with mine. It healed perfectly.

- Q: From the Scarlet Letter, Ch. 10-12

- Haven't read this book in years but I believe he goes back to the scaffold at night because he is being eaten away by guilt. It is a type of redemptive action, just as Hester had to stand there and be judged for her sins he feels the need to also stand there on the scaffold with Hester (theoretically) and be judged/punished as well, the only difference, of course, is that he does it under the cloak of night, when no one can see him.

- Q: Specific requirements, the civil code is what ah! Thank you very much, I am lack of this kind of information, I hope you can tell me which of the following

- The surface of the steel pipe shall be smooth and free of cracks, scars, delamination, dislocation, hard bending, burrs, indentation and deep scratches.The outer diameter of steel pipe 48mm allowable deviation is 0.5mm; the thickness of the wall 3.5mm allowable deviation of.0.5mm; steel pipe surface cutting oblique deviation 1.7mm;Dressing should be checked once a year. When the examination, should be in serious pipe corrosion in the selected three roots in each part of the serious corrosion of transverse sampling inspection, the outer surface of the steel pipe corrosion depth allowable deviation is less than 0.5mm, more than the provisions shall not be used.All new and old steel pipes must be painted with anti rust paint.

- Q: Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

- Q: What are the requirements for the construction of the scaffolding structure?

- The scaffold structure is basically in the two-dimensional grid and a substantially two-dimensional outer grid connected grid, each of the included in the expected load conditions of scaffolding structure after long time has a bearing component of relatively stable strength. The anchor is connected with the support arm and has a first leg in the form of a bar or rod. The anchor may be aligned such that the first leg is substantially parallel to the longitudinal axis of the arm, and the distal end of the first leg extends beyond the arm. The structure of the scaffold also comprises one or more platforms, each platform is arranged between the two corresponding bearing bars of the inner and outer grid frames at the same height.

Send your message to us

Cup Lock Scaffolding Cuplock System for Construction Formwork Building CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords