Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

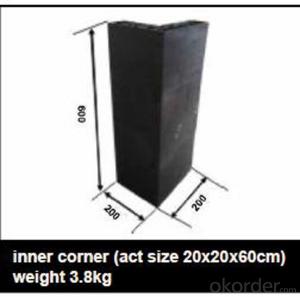

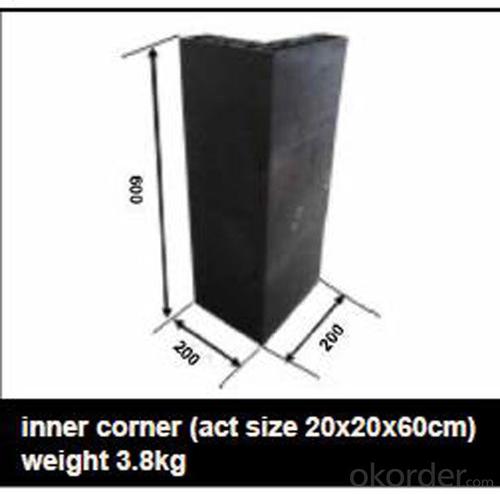

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Q: Can steel frame formwork be used for bridge construction?

- Indeed, bridge construction can make use of steel frame formwork. This system, known for its versatility and durability, provides the necessary support and structure for concrete formations, including bridges. Engineers can benefit from its flexibility in design, allowing them to create intricate shapes and sizes for various bridge components like piers, abutments, and beams. Moreover, the steel frame formwork system can withstand the immense loads and pressures involved in bridge construction, making it an ideal choice for such projects. Furthermore, this system facilitates quicker construction due to its easy assembly, disassembly, and potential for reuse in multiple endeavors.

- Q: What are the different types of joints used in steel frame formwork?

- The different types of joints used in steel frame formwork include butt joints, lap joints, tongue and groove joints, and corner joints.

- Q: Can steel frame formwork be used in projects with limited construction site security or theft risks?

- Yes, steel frame formwork can be used in projects with limited construction site security or theft risks. Steel formwork is sturdy and durable, making it less susceptible to theft or damage compared to other types of formwork materials. Its robust construction provides added protection against unauthorized access or tampering, making it a suitable choice for projects with limited security measures in place.

- Q: Can steel frame formwork be used for the construction of hospitality facilities?

- Indeed, hospitality facilities can be constructed using steel frame formwork. This versatile and long-lasting construction method is commonly employed in a variety of building projects, including those in the hospitality sector. Steel frame formwork consists of easily assembled and disassembled steel frames, adding flexibility to the construction process. The use of steel frame formwork offers numerous benefits for the construction of hospitality facilities. Firstly, steel is a robust and enduring material capable of withstanding the heavy loads and stresses typically encountered in such establishments. This ensures the stability and safety of the structure. Moreover, steel frame formwork enables efficient construction processes. The frames can be effortlessly adjusted and reused, resulting in reduced construction time and costs. This advantage is particularly valuable in hospitality projects, where meeting project deadlines often depends on swift construction. Furthermore, steel frame formwork facilitates a high level of accuracy and precision during construction. The frames are meticulously designed to be straight and level, guaranteeing that the resulting structure is of superior quality and adheres to design specifications. This aspect is crucial in hospitality facilities, as aesthetics and attention to detail are paramount in creating an inviting and visually appealing environment for guests. To conclude, steel frame formwork is indeed a suitable choice for the construction of hospitality facilities. Its strength, durability, efficiency, and precision provide a solid foundation for the creation of welcoming and well-constructed establishments in the hospitality industry.

- Q: Steel frame wood fire doors are graded? Grade A, B, C?

- . When the condition is limited, the moisture content should not be greater than the local equilibrium moisture content. Wood fire doors for the hardware fittings must be fire-resistant hardware accessories, the main hardware accessories: Fire hinge (hinge), fire plugs, fire doors, fire order and fire door closer, etc.. In the fire resistance test, wood fire doors should be required in the fire resistance time to meet the standard stipulated conditions: integrity: a) discontinuous 10s above the flame burning in the back fire surface; b) in the unexposed surface if cracks, holes or other pore and does not appear the flame, also cannot be away from combustibles these pores 20mm30mm distance ignition in 10s30s; c) samples not collapse. Heat insulation: the average temperature rise of the temperature measuring point on the wooden fire door should be 140 DEG C or the temperature rise of any temperature measuring point will reach to 180 centigrade. Two, product consistency checking consistency of products in the field, should check the following: 1, the appearance of the product is consistent with the standard requirements; 2, the identity of the product is consistent with the standard requirements; 3, the product structure is consistent and test report

- Q: How does steel frame formwork ensure proper alignment and leveling of the concrete structure?

- Steel frame formwork ensures proper alignment and leveling of the concrete structure through its sturdy and rigid construction. The steel frames are designed and manufactured with precision to provide a stable and reliable framework for pouring concrete. Firstly, the steel frame formwork is assembled and fixed firmly in place before the concrete is poured. The frames are interconnected and secured together, creating a solid structure that can withstand the pressure and weight of the wet concrete. This prevents any movement or shifting during the pouring and curing process, ensuring that the concrete remains in the desired position and form. Additionally, steel frame formwork is carefully designed with adjustable components. This allows for easy and precise leveling of the formwork to ensure a perfectly flat and even surface for the concrete. The adjustable components, such as props, wedges, and screws, can be manipulated to raise or lower specific areas of the formwork as needed. This level of adjustability enables the formwork to accommodate any irregularities or variations in the ground or structure, ensuring that the concrete is poured evenly and accurately. Furthermore, the steel frame formwork provides a straight and true framework for the concrete structure. The frames are manufactured with high accuracy and dimensional stability, ensuring that they maintain their shape and alignment throughout the construction process. This eliminates any potential for distortion or misalignment of the concrete structure, resulting in a finished product that is structurally sound and aesthetically pleasing. In summary, steel frame formwork ensures proper alignment and leveling of the concrete structure by providing a stable and rigid framework, adjustable components for precise leveling, and accurate dimensional stability. These qualities contribute to the successful construction of a concrete structure that is both structurally reliable and visually appealing.

- Q: How to fix the glass brick on the steel frame

- Generally can use glass glue and steel frame fixed, pay attention not to use the corrosion of the glue, general neutral can.

- Q: Can steel frame formwork be used for both horizontal and vertical concrete elements?

- Yes, steel frame formwork can be used for both horizontal and vertical concrete elements. It is a versatile and robust system that can be easily adjusted and reused for various construction projects.

- Q: How does steel frame formwork handle the load distribution of a structure?

- A versatile and strong system utilized in construction for effective load distribution of structures is steel frame formwork. The main characteristic of this formwork is its ability to evenly distribute weight and forces on the structure, ensuring a stable and balanced load distribution. To begin with, steel frame formwork is comprised of interconnected rigid and strong steel panels capable of withstanding heavy loads. These panels are assembled and fixed together to create a framework that serves as a support system for the structure. The design of the steel frame formwork is such that it evenly distributes the load across the panels, preventing concentration of forces in specific areas. Moreover, steel frame formwork offers high customization, allowing for precise adjustment and alignment of the panels. This adaptability enables the formwork system to accommodate structures with complex geometries or irregular shapes. By ensuring accurate alignment of the panels, the load distribution is optimized, avoiding localized stress points and ensuring a uniform distribution of forces. Furthermore, steel frame formwork has a high load-bearing capacity due to the strength and durability of steel. Steel is known for its robustness and resistance to deformation, enabling it to handle heavy loads without compromising the stability of the structure. The use of steel in the formwork system ensures even and efficient load distribution, minimizing the risk of structural failure or collapse. Additionally, steel frame formwork allows for the integration of additional reinforcement elements, such as steel bars or mesh, which further enhance the load distribution capabilities of the structure. These reinforcements provide additional strength and stiffness, ensuring that the load is evenly distributed across the entire formwork system. In conclusion, steel frame formwork is an excellent solution for managing load distribution in structures. Its strength, adaptability, and high load-bearing capacity enable it to evenly distribute weight and forces on the structure, ensuring a stable and balanced load distribution. This guarantees the structural integrity and safety of the building, making steel frame formwork a popular choice in the construction industry.

- Q: How does steel frame formwork handle the placement of fire-rated barriers and partitions within the concrete structure?

- Steel frame formwork provides a robust and efficient solution for the placement of fire-rated barriers and partitions within a concrete structure. With its strong and durable nature, steel frame formwork ensures the accurate positioning and alignment of these fire-rated elements. The rigid framework allows for precise installation, ensuring that the barriers and partitions are securely embedded within the concrete structure, providing reliable fire protection. Additionally, steel frame formwork allows for easy adjustment and modification when necessary, making it a versatile choice for incorporating fire-rated barriers and partitions into the concrete structure.

Send your message to us

Scaffolding In Riyadh Formwork Scaffolding in Riyadh with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords