SBS Waterproofing Membrane In Composite Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

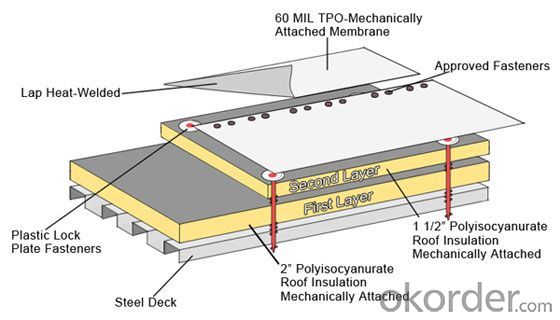

sbs waterproof membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

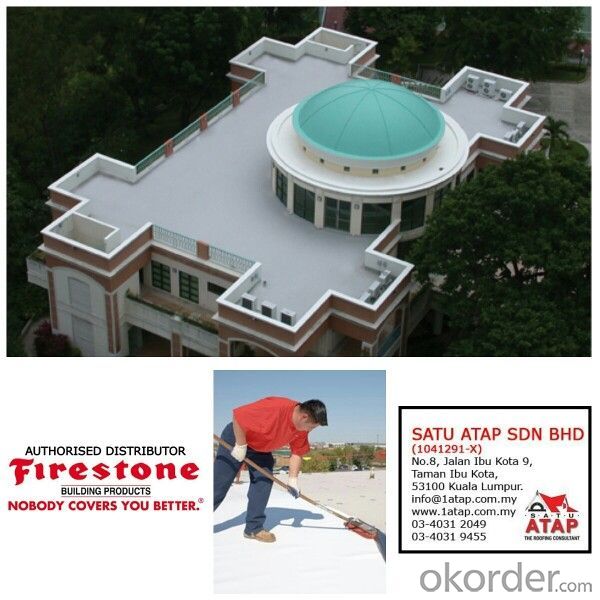

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

product show

FAQ

- Q: Can waterproofing membranes be used on outdoor patios?

- Yes, waterproofing membranes can be used on outdoor patios. They are an effective way to protect the patio from water damage and can help to prevent leaks and moisture penetration. Waterproofing membranes create a barrier between the patio surface and water, keeping it dry and extending its lifespan.

- Q: Can waterproofing membranes be used on concrete fountains?

- Yes, waterproofing membranes can be used on concrete fountains. Concrete fountains are often exposed to water and can be prone to leaks and moisture damage. Applying a waterproofing membrane to the concrete surface helps to create a barrier that prevents water penetration and protects the fountain structure. Waterproofing membranes are designed to be flexible, durable, and resistant to water, making them an ideal solution for concrete fountains. They can be applied to the interior and exterior surfaces of the fountain, ensuring complete protection against water damage. By using waterproofing membranes, the lifespan of the concrete fountain can be extended, and maintenance costs can be reduced.

- Q: Can a waterproofing membrane be used on balconies or decks?

- Balconies or decks can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to offer a shield against water and moisture, making them an ideal solution for outdoor spaces that are constantly exposed to the elements. Their composition typically includes rubber, PVC, or bitumen, and they are directly applied to the surface of the balcony or deck. By doing so, they effectively prevent water from penetrating the underlying structure, safeguarding it against potential damage caused by moisture. Waterproofing membranes prove particularly advantageous in areas prone to heavy rainfall, snow, or high humidity, as they effectively prolong the lifespan of the balcony or deck by preventing water-related issues such as rot, mold, or deterioration. Moreover, these membranes also serve as an additional layer of protection against harmful UV rays, effectively preventing discoloration or fading of the balcony or deck surface. Ultimately, opting for a waterproofing membrane for balconies or decks is a wise investment that ensures their durability while maintaining their aesthetic appeal.

- Q: Can a waterproofing membrane be used for mechanical rooms?

- Yes, a waterproofing membrane can be used for mechanical rooms. Mechanical rooms often house various equipment and systems that require protection from water damage. Waterproofing membranes provide a barrier against water intrusion, preventing moisture from penetrating the structure and potentially causing damage to the mechanical equipment. By applying a waterproofing membrane to the walls, floors, and even ceilings of a mechanical room, it helps to ensure a watertight environment that prolongs the lifespan of the equipment and reduces the risk of water-related issues. Additionally, waterproofing membranes can also provide protection against other forms of moisture, such as condensation or high humidity levels, which can be detrimental to the functionality of mechanical systems. Overall, using a waterproofing membrane in mechanical rooms is a sensible and effective measure to safeguard the equipment and maintain a dry and functional environment.

- Q: Can a waterproofing membrane be applied on top of existing surfaces?

- Indeed, one can indeed apply a waterproofing membrane onto preexisting surfaces. Nevertheless, it is crucial to guarantee that said surface is clean, dry, and in proper condition prior to membrane application. Prior to installation, any cracks, holes, or damages must be repaired. Moreover, the nature of the existing surface may impact the type of waterproofing membrane that can be utilized. It is highly advised to seek guidance from a proficient waterproofing contractor to ascertain the most appropriate membrane for the given surface and circumstances.

- Q: Can a waterproofing membrane enhance the durability or lifespan of a structure?

- Yes, a waterproofing membrane can enhance the durability and lifespan of a structure by providing a protective barrier against water infiltration, preventing damage from moisture, leaks, and deterioration caused by water-related issues.

- Q: Does a waterproofing membrane require any special maintenance?

- Yes, a waterproofing membrane does require some special maintenance. While it is designed to be durable and withstand various weather conditions, regular maintenance is necessary to ensure its effectiveness and longevity. Some maintenance tasks include: 1. Regular inspections: Check the membrane for any signs of damage, such as cracks, tears, or punctures. Inspect the seams and edges to ensure they are properly sealed. 2. Clean the surface: Remove any debris, dirt, or vegetation that may have accumulated on the membrane. This can be done using a broom, brush, or pressure washer (if recommended by the manufacturer). 3. Clear drains and gutters: Ensure that the drains and gutters connected to the membrane are not clogged or blocked. This will prevent water from pooling on the surface and potentially causing damage. 4. Repair any damages: If any cracks, tears, or punctures are found, they should be repaired promptly to prevent water leakage. Follow the manufacturer's instructions for the appropriate repair method and materials. 5. Regularly check the waterproofing system: If the membrane is part of a larger waterproofing system, such as a basement or roof, it is important to inspect and maintain the entire system. This may involve checking the integrity of other components, such as drainage pipes or flashing. 6. Consider professional maintenance: Depending on the size and complexity of the waterproofing system, it may be beneficial to hire a professional maintenance service. They can conduct thorough inspections, perform necessary repairs, and provide expert advice on maintaining the membrane. By following these maintenance practices, you can ensure that your waterproofing membrane remains in good condition and effectively protects your structure from water damage.

- Q: Can a waterproofing membrane be used on concrete block surfaces?

- Concrete block surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are specifically designed to act as a shield against moisture and water infiltration, which makes them a popular choice for safeguarding concrete block surfaces against water-related harm and leaks. To achieve this, the membranes are either applied as a liquid or in sheet form, bonding to the surface of the concrete blocks and forming a protective layer that prevents water from seeping through. By reducing the risks of water damage, mold growth, and deterioration, the lifespan of the concrete blocks can be extended with the help of this waterproofing membrane. It is crucial to select a membrane that is specifically tailored for concrete block surfaces, and to follow the manufacturer's instructions carefully during installation to ensure optimal results.

- Q: Can waterproofing membranes be used on concrete countertops?

- Concrete countertops can indeed benefit from the application of waterproofing membranes. These membranes are specially crafted to thwart the infiltration of water and can be utilized on diverse surfaces, including concrete. By opting for a waterproofing membrane on a concrete countertop, one can effectively safeguard it against water harm, staining, and possible structural concerns. Furthermore, these membranes can augment the countertop's resilience and lifespan by averting moisture-induced problems, such as cracking or warping. It is imperative to verify that the selected waterproofing membrane is concrete-compatible and appropriate for countertop use.

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Certainly! When installing tile or stone, it is highly recommended to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water from seeping into the underlying layers and causing damage. It is especially beneficial in wet areas, such as bathrooms, showers, and kitchen backsplashes. There are different types of waterproofing membranes available, such as liquid-applied, sheet, and fabric membranes. These can be applied to the substrate before installing the tile or stone, creating a waterproof layer that keeps the area dry and free from water-related issues. In addition to safeguarding against water damage, a waterproofing membrane also helps to prevent the growth of mold and mildew, which can be detrimental to both the installation and the health of those using the space. It is essential to note that proper installation of the waterproofing membrane is crucial for its effectiveness. Following the guidelines and best practices provided by the manufacturer ensures a tight seal and complete coverage. Overall, integrating a waterproofing membrane with tile or stone installations is a prudent decision. It enhances the project's durability and longevity while providing peace of mind against potential water damage.

Send your message to us

SBS Waterproofing Membrane In Composite Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords