SBS Waterproof Membrane APP Modified Bitumen Waterproofing Membrane Roof Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

SBS modified bitumen waterproof membranes use high quality needle punched polyester mat or fiberglass compound mat as the base reinforcement. And use SBS modified bitumen as the dip-coat material. The SBS modified bitumen waterproof membrane are widely used for roof waterproof projects.

Main performance

1.Good low temperature performance, especially suitable for cold regions.

2.Good weather resistance, tensile property, extensibility, corrosion resistance and so on.

3.Strong adaptability for substrate shrinkage, deformation and cracks.

4.Convenient to apply: use heat fusion method in all seasons.

5. Meet national standards.

6.ISO Certification.

Technical Parameters

No. |

Item | Index | |||||||||

Ⅰ | Ⅱ | ||||||||||

PY | G | PY | G | PYG | |||||||

1 |

soluble content(g/m2) ≥ | 3mm | 2100 | — | |||||||

4mm | 2900 | — | |||||||||

5mm | 3500 | ||||||||||

test phenomenon | — | non-ignitable | — | non-ignitable | — | ||||||

2 |

heat resistance | °C | 90 | 105 | |||||||

≤mm | 2 | ||||||||||

test phenomenon | no flow or drippage | ||||||||||

3

|

low temperature flexibility °C | -20 | -25 | ||||||||

no flaw | |||||||||||

4

|

water tightness 30min

|

0.3Mpa |

0.2Mpa |

0.3Mpa

| |||||||

5 |

tension | tension of maximum peak rate%≥ | 500 | 350 | 800 | 500 | 900 | ||||

tension of maximum peak rate%≥ | — | — | — | — | — | ||||||

test phenomenon | no cracks or separate | ||||||||||

6 |

elongation

| elongation of maximum peak rate%≥ |

30 |

— |

40 |

— | |||||

elongation of second peak rate%≥peak rate%≥ |

— |

— |

15 | ||||||||

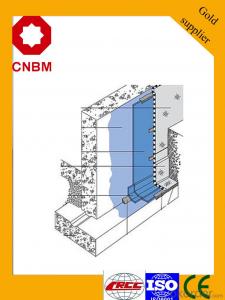

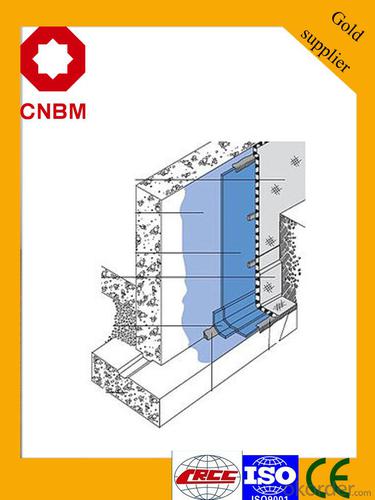

Product usage

The waterproof , dampproof and seepage-proofing of roof, basement, tunnel and so on.

Packaging and storage

1)Avoid insolating, raining; the temperature shall be 4-45°C;

2)Keep them stand up and vertical;

3)Do not stack up over two tiers, avoid tilting and lateral drift.

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Is a waterproofing membrane resistant to rodent or insect infestation?

- A waterproofing membrane has the ability to resist infestation from rodents or insects. Most waterproofing membranes are constructed using materials that rodents or insects find unappealing, such as bitumen or synthetic polymers. Furthermore, these membranes are typically installed in a manner that eliminates any gaps or openings through which pests could enter. However, it should be noted that no waterproofing system is completely impervious to infestation. If there are existing entry points or if the membrane is damaged or improperly installed, rodents or insects may still be capable of breaching the waterproofing system. Regular inspection and maintenance are essential to ensure the integrity of the waterproofing membrane and to prevent any infestation from occurring.

- Q: How does a waterproofing membrane adhere to a variety of surfaces?

- A waterproofing membrane adheres to a variety of surfaces by utilizing a strong adhesive backing or by being applied with a suitable adhesive. This allows it to bond effectively to different materials such as concrete, wood, metal, or even existing waterproofing layers. Additionally, some membranes may also have self-adhesive properties that eliminate the need for an external adhesive.

- Q: Can a waterproofing membrane be used in basements and foundations?

- Yes, a waterproofing membrane can be used in basements and foundations. Waterproofing membranes are specifically designed to prevent the penetration of water and moisture, making them an effective solution for protecting basements and foundations from water damage.

- Q: Are waterproofing membranes resistant to punctures?

- Yes, waterproofing membranes are designed to be resistant to punctures. They are typically made from durable materials that can withstand external forces without tearing or puncturing, ensuring long-lasting protection against water intrusion.

- Q: How does a waterproofing membrane compare to other waterproofing methods?

- A waterproofing membrane is a highly effective and reliable method of waterproofing compared to other traditional waterproofing methods. Here are some ways in which a waterproofing membrane stands out: 1. Superior Protection: A waterproofing membrane provides a continuous and seamless barrier against water intrusion. Unlike other methods like waterproof paints or coatings, which may crack or peel over time, a membrane can withstand extreme weather conditions and prevent water from seeping through. 2. Longevity: Waterproofing membranes are designed to be durable and long-lasting. They are usually made from materials such as rubber, PVC, or modified bitumen, which have excellent resistance to wear and tear. As a result, they can provide a reliable waterproofing solution for many years. 3. Versatility: Waterproofing membranes can be applied to various surfaces, including concrete, metal, and wood. They can be used in a wide range of applications such as roofs, basements, foundations, and even tunnels. This versatility makes them suitable for both residential and commercial projects. 4. Flexibility: Waterproofing membranes are flexible, allowing them to conform to the shape and contours of the surface they are applied to. This flexibility ensures that the membrane can accommodate any movements or shifts in the structure, preventing any potential cracks or gaps that could lead to water leakage. 5. Ease of Installation: Installing a waterproofing membrane is usually straightforward and can be done by professionals or experienced DIYers. The membrane is typically rolled out onto the surface, adhered with adhesive or heat-welded, and then sealed at the edges and seams. This ease of installation makes it a popular choice for both new construction and retrofit projects. 6. Cost-Effectiveness: While the initial cost of installing a waterproofing membrane may be higher compared to other methods, its long-term cost-effectiveness makes it a wise investment. The durability and longevity of the membrane mean that there will be fewer maintenance and repair costs over time, saving money in the long run. In conclusion, a waterproofing membrane offers superior protection, longevity, versatility, flexibility, ease of installation, and cost-effectiveness compared to other waterproofing methods. Its ability to provide a continuous and reliable barrier against water intrusion makes it a preferred choice for many construction projects.

- Q: Is a waterproofing membrane resistant to solvents or chemical spills?

- Yes, a waterproofing membrane is typically resistant to solvents or chemical spills. Waterproofing membranes are designed to provide a protective barrier against water and other liquids, including solvents and chemicals. These membranes are often made of materials such as PVC, TPO, or EPDM, which have excellent resistance to various solvents and chemicals. However, the specific resistance may vary depending on the type and composition of the membrane. It is always recommended to check the manufacturer's specifications and consult with professionals to ensure the membrane's compatibility with specific solvents or chemicals before installation.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- A waterproofing membrane is viable for use in areas subjected to heavy foot traffic or substantial loads. These membranes are created to serve as a protective barrier against water infiltration and can withstand different forms of stress, including foot traffic and heavy loads. However, it is imperative to select a waterproofing membrane that is explicitly designed for such circumstances. Multiple membrane options are available, each possessing varying levels of durability and strength. It is of utmost importance to seek guidance from a professional waterproofing expert or manufacturer to ensure that the chosen membrane is suitable for the specific requirements of the high foot traffic or heavy load area. Proper installation and maintenance of the membrane are also crucial for its long-term effectiveness in these conditions.

- Q: Can a waterproofing membrane be used for a school building foundation?

- Yes, a waterproofing membrane can be used for a school building foundation. Waterproofing membranes are commonly used in construction to prevent water penetration into the foundation, which helps protect the building from potential water damage.

- Q: Where are waterproofing membranes commonly used?

- Waterproofing membranes are commonly used in construction, particularly in areas such as basements, roofs, foundations, and bathrooms, where protection against water infiltration and moisture is crucial.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- Yes, a waterproofing membrane can be used in conjunction with expansion joint systems. Waterproofing membranes are commonly used to prevent water infiltration and protect structures from moisture damage. Expansion joint systems, on the other hand, are installed to allow for movement and accommodate thermal expansion and contraction in structures. By combining the use of a waterproofing membrane and expansion joint systems, it is possible to provide both waterproofing and movement accommodation in a structure. This ensures that the structure remains protected from water damage while allowing for necessary movement. It is important to properly design and install both the waterproofing membrane and the expansion joint system to ensure their compatibility and effectiveness.

Send your message to us

SBS Waterproof Membrane APP Modified Bitumen Waterproofing Membrane Roof Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords