SBS Modified Bitumen Waterproofing Membrane Waterstop Asphalt Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

Item | SBS/APP Basement Waterproofing Membrane | |||||

Brand | CNBM | |||||

Grade | First | Second | ||||

Base | PY | G | PYG | |||

Cover | PE | S | M | |||

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

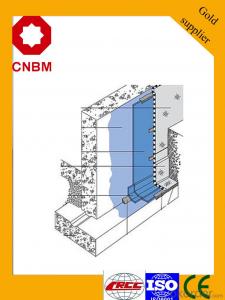

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application method:

1.Make sure the roof deck smooth ,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2.There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3.After application ,a full serious inspection is required to make sure no air bubble ,no fold,no falling away etc to guarantee the waterproof life.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Product usage of pe compound waterproof membrane

The products are widely used in projects of compound geomembrane impervious

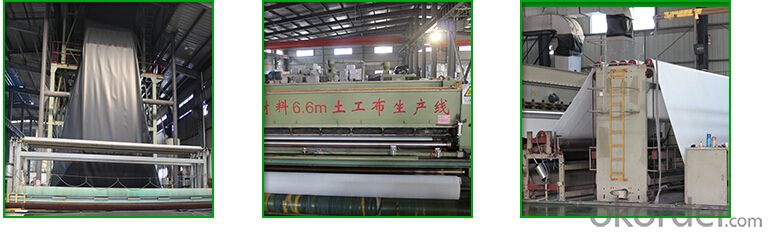

Product line&test

♦Product line

From raw materials to finished products, every process is tested and controlled professionally and seriously by our professional machines and person.

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Why choose us ?

We have 20 years manufacturer experience

10000-30000 square meter factory size,more than 10 production lines

We will be your best partner,provide high quality products with CE,ISO,SGS

approved in competitive prive,sincerely hope to make a win-win cooperation with you.

FAQ

- Q: Is a waterproofing membrane necessary for all types of construction?

- Not all types of construction require a waterproofing membrane, but it is highly recommended for certain projects. The necessity of a waterproofing membrane depends on various factors, including the construction's location, purpose, materials used, and potential exposure to water or moisture. In areas where water intrusion is common, such as basements, foundation walls, roofs, bathrooms, and high humidity areas, a waterproofing membrane is crucial. These areas are prone to water damage, which can lead to structural problems, mold growth, and degradation of building materials. Waterproofing membranes create a reliable barrier against water penetration, preventing any damage from moisture. They are typically made from materials like asphalt, rubber, or polyethylene, and are applied as a thin layer to create a watertight seal. Some membranes also provide insulation benefits, improving the construction's energy efficiency. While a waterproofing membrane may increase construction costs, its advantages outweigh the expenses in the long term. It safeguards the building's structural integrity, extends its lifespan, and prevents costly repairs or renovations due to water damage. However, not all construction projects require a waterproofing membrane. For instance, buildings in arid regions or areas with little rainfall may not need extensive waterproofing measures. Likewise, certain construction types, like open-air structures or temporary installations, may not require a waterproofing membrane. Ultimately, the decision to include a waterproofing membrane in a construction project should be based on a thorough evaluation of the specific conditions, risks, and project requirements. Seeking guidance from a professional architect or engineer can help determine the necessity of a waterproofing membrane and the most suitable type for the construction.

- Q: Can a waterproofing membrane be installed over existing coatings or sealants?

- Installing a waterproofing membrane over existing coatings or sealants is possible, but it depends on the condition of the surface. Before proceeding, it is crucial to ensure that the surface is clean, dry, and devoid of any loose or damaged material. Adequate surface preparation plays a vital role in ensuring proper adhesion of the new membrane and effective waterproofing. To avoid any potential problems or system failure, it is advisable to seek advice from a professional regarding the compatibility of the existing coatings or sealants with the waterproofing membrane.

- Q: Can waterproofing membranes be used on concrete fountains?

- Yes, waterproofing membranes can be used on concrete fountains. These membranes are designed to provide a protective barrier against water penetration, which is essential for preserving the structural integrity and preventing water damage in concrete fountains.

- Q: Can a waterproofing membrane be used for a foundation wall damp proofing?

- Yes, a waterproofing membrane can be used for foundation wall damp proofing. A waterproofing membrane is designed to prevent the passage of water and can be used to create a barrier between the foundation wall and the surrounding soil. This barrier can help to prevent moisture from seeping into the foundation wall, which can lead to dampness and potential water damage. By applying a waterproofing membrane to the foundation wall, it can effectively damp proof the wall and protect it from water intrusion. However, it is important to ensure that the waterproofing membrane is installed correctly and that all joints and seams are properly sealed to provide a continuous barrier against water.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Indeed, temporary structures or tents can benefit from the utilization of a waterproofing membrane. These membranes are specifically crafted to create a safeguarding shield against water, thwarting any potential harm caused by water infiltration. Consequently, they prove to be an excellent selection for temporary structures or tents, ensuring that the interior remains dry in inclement weather or damp environments. Furthermore, the lightweight and pliable nature of waterproofing membranes simplifies their installation and removal, which is particularly advantageous for temporary structures or tents that necessitate relocation or disassembly.

- Q: Are waterproofing membranes suitable for underground parking garages?

- Yes, waterproofing membranes are suitable for underground parking garages. They provide an effective barrier against water infiltration, preventing damage to the structure and protecting against potential leaks and moisture-related issues. Waterproofing membranes are designed to withstand the high water pressure typically associated with underground environments, making them an ideal solution for ensuring the longevity and durability of underground parking garages.

- Q: Does a waterproofing membrane require any maintenance?

- Maintenance is indeed required for a waterproofing membrane. Despite its ability to offer lasting defense against water damage, regular maintenance is vital to maintain its effectiveness. This involves checking the membrane for any indications of harm or wear, such as cracks or punctures, and promptly fixing them. Moreover, regularly cleaning the membrane to eliminate dirt, debris, and potential contaminants will assist in preserving its performance. It is advisable to have professionals who specialize in waterproofing systems carry out regular maintenance to guarantee proper upkeep and prevent any potential problems.

- Q: Can a waterproofing membrane be used for dams?

- Yes, a waterproofing membrane can be used for dams. These membranes are designed to prevent water leakage by creating a barrier that is resistant to water penetration. They can be applied to the surface of the dam to ensure its integrity and prevent seepage of water through the structure.

- Q: How does a waterproofing membrane handle movement or settling of the structure?

- A waterproofing membrane is designed to accommodate the movement or settling of a structure in a few different ways. Firstly, a waterproofing membrane is typically flexible and elastomeric, meaning it can stretch and move with the structure without cracking or tearing. This allows it to withstand minor shifts or settlements in the building without compromising its ability to keep water out. Additionally, some waterproofing membranes have built-in reinforcing materials, such as polyester or fiberglass, which provide added strength and durability. These reinforcements help the membrane resist potential damage caused by movement, settling, or even structural vibrations. Furthermore, many waterproofing systems include provisions for expansion joints or movement joints, which are intentionally created gaps or spaces in the structure to allow for natural movement. These joints are then sealed using flexible materials compatible with the waterproofing membrane. This allows the membrane to accommodate the anticipated movement or settling within these joints, preventing leaks or damage to the water barrier. In summary, a waterproofing membrane is designed to handle movement or settling of a structure by being flexible, elastomeric, and capable of stretching without tearing. Additionally, reinforcements and the incorporation of expansion joints further enhance the membrane's ability to accommodate movements and maintain its integrity as a waterproof barrier.

- Q: Can a waterproofing membrane be used on foam block surfaces?

- Yes, a waterproofing membrane can be used on foam block surfaces. Foam blocks, such as expanded polystyrene (EPS) or extruded polystyrene (XPS), are often used as insulation in buildings. However, foam blocks are not inherently waterproof and can absorb moisture if left unprotected. To prevent water infiltration and potential damage, a waterproofing membrane can be applied to the foam block surfaces. The membrane acts as a barrier, preventing water from seeping into the foam and protecting it from moisture-related issues such as mold, mildew, or degradation. It is important to select a waterproofing membrane that is compatible with foam block surfaces and follow the manufacturer's instructions for proper application. Additionally, it is recommended to consult with a professional or a building engineer to ensure the appropriate waterproofing solution is chosen for the specific foam block application.

Send your message to us

SBS Modified Bitumen Waterproofing Membrane Waterstop Asphalt Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords