SBS Modified Bitumen Waterproofing Membrane Waterproof Asphalt Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

SBS Waterproof Material Self Adhesive Aluminium Membrane is produced with SBS elastomer and bitumen as raw materials, using polyethylene film.

Aluminium foil coated on the upward or no file(both side self-adhesive) while self-adhesive protection layer on the downward

surface.It has a widely prospect new contruction waterproof materials. Good self-adhesion, no leaking,cold flexibility,especially

in self-adhesion. That is unque product in waterproof and application.

Packaging & Shipping

use advanced equipment to produce 2 meters WSBS Width Elastomeric Modified Bitumen Waterproofing Membrane which is made of bitumen modified with Styrene-Butadiene-Styrene (SBS) as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane).

Package and transportation-- SBS waterproof membrane / APP waterproof membrane / Asphalt waterproof membrane for building waterproofing construction :

1. Torch on bitumen membrane sheets 4mm should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away from sunshine and rainwater.

.

Advantagee

1.1m or 2m width, we can produce as your requirment

2.Simple and Efficient Construct, Greatly Saving Construct Period

3.Advanced Production Line

4.Excellent Comprehensive Physical Properties

5.Stable Dimension

6.Wide Adaptability of Facing Material

7. Cold-applied construction with no open flame and self-adhesion without bonding agent make it safe, low- carbon, environmental, and economical.

8. Excellent adhesive performance guarantees the integrity of waterproof layer.

9. Good rubber elasticity, elongation and shear stress.

10. Good low-temperature property.

Application method

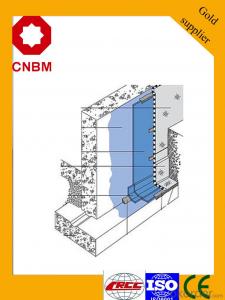

1) Widely used in the industrial and civil building roofing, underground, pool, tunnel, wooden and metal roofing.

2) Specially applied in the oil depot chemical factory, garment factory, and granary.

3) Especially used in cold places.

4) Tape used for sealing all construction material surfaces.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Storage:

Different types or specifications of products should be separated, not mixed.

Keep it dry and ventilated, protected from the sun or rain.

Storage temperature should never be higher than 45 °C. Pile up the membranes flatwise whose stockpile height never exceeds five layers. One layer is guaranteed if it is placed vertically.

Prevent it from inclination or In the process of transportation, it should be lying in case of inclination or lateral pressure. If necessary, cover it with felt-cloth.

Storage time is at least one year from manufacture date on if the product is under normal operation of storage.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be applied to both interior and exterior surfaces?

- Both interior and exterior surfaces can benefit from the application of a waterproofing membrane. Its main objective is to safeguard against water infiltration and shield the underlying surfaces. Regardless of whether it is used indoors or outdoors, the membrane serves the same purpose of establishing a barrier against moisture. Basements and crawl spaces commonly utilize interior waterproofing membranes to prevent water from seeping into the building interior. On the other hand, exterior waterproofing membranes are typically applied to the outside walls and foundations to guard against water penetration from rain, groundwater, and other external sources. Both types of membranes are engineered to be long-lasting, adaptable, and water-resistant, ensuring the durability and structural soundness of the surfaces they are applied to.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction projects to prevent water infiltration and protect the building from water damage. The membrane is applied to surfaces such as walls, floors, and roofs, creating a barrier that prevents water from seeping through. In theaters and concert halls, where the protection of the building structure and equipment is crucial, waterproofing membranes can be highly beneficial. They can help prevent water damage to sensitive equipment, such as audiovisual systems, lighting fixtures, and musical instruments. Additionally, a waterproofing membrane can help maintain a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. Overall, using a waterproofing membrane in theaters or concert halls can help ensure the longevity and functionality of the building while providing a safe and enjoyable experience for everyone involved.

- Q: Do waterproofing membranes require maintenance?

- Yes, waterproofing membranes do require maintenance. Regular inspection and maintenance are necessary to ensure the effectiveness and longevity of the waterproofing system. This may include checking for any damages or wear and tear, clearing debris, ensuring proper drainage, and addressing any potential issues promptly.

- Q: Can a waterproofing membrane be used for seawalls or bulkheads?

- Yes, a waterproofing membrane can be used for seawalls or bulkheads. These membranes are designed to provide a barrier against water penetration and can effectively protect structures from the corrosive effects of saltwater and wave action. This makes them suitable for use in constructing and maintaining seawalls and bulkheads, ensuring their durability and longevity.

- Q: Can a waterproofing membrane be used for zoos or aquariums?

- Yes, a waterproofing membrane can be used for zoos or aquariums. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can be an effective solution for preventing water damage and leakage in these types of environments. They can be applied to various surfaces, such as concrete or steel, to create a watertight seal and prevent water from seeping into the structure or habitat. Waterproofing membranes are often used in aquariums to ensure that the tanks remain water-tight and do not leak, which is crucial for the well-being of the aquatic animals. Similarly, in zoos, waterproofing membranes can be used in animal enclosures or exhibit areas to prevent water damage to the structures and maintain a safe and healthy environment for the animals. Additionally, the membranes can also protect against potential chemical spills, as they are often resistant to various chemicals and can withstand harsh conditions. Overall, waterproofing membranes are a suitable option for zoos or aquariums as they provide an effective solution for maintaining the integrity of the structures and habitats, preventing water damage, and ensuring the safety and well-being of the animals.

- Q: What kind of waterproofing membrane, waterproofing membrane is how to classify their respective advantages?

- TPO waterproofing membrane: strictly speaking TPO waterproofing membrane is EPDM (EPDM) and PVC combination, most of the performance are lower than EPDM.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. In interior applications, such as basements or bathrooms, a waterproofing membrane can be installed on walls or floors to prevent water or moisture from seeping through. This helps to protect the underlying structure from damage caused by water intrusion. In exterior applications, a waterproofing membrane can be applied to the exterior walls or foundations of a building to prevent water from penetrating into the structure. This is especially important in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane helps to keep the interior of the building dry and free from water damage. Overall, the use of a waterproofing membrane in both interior and exterior applications is essential for ensuring the longevity and durability of a structure by protecting it from water-related issues.

- Q: Can a waterproofing membrane be used for bridges or parking decks?

- Bridges or parking decks can benefit from the use of a waterproofing membrane. These membranes are specifically designed to safeguard structures from water damage and are commonly employed in construction projects for this purpose. Since bridges and parking decks are exposed to various weather conditions, such as rain, snow, and ice, which can cause concrete and steel components to deteriorate, it is important to apply a waterproofing membrane to prevent moisture from seeping in. This will help prevent corrosion, cracking, and other forms of deterioration. Moreover, waterproofing membranes offer additional advantages like improved durability, increased lifespan, and reduced maintenance costs for these structures. Therefore, using a waterproofing membrane is highly recommended to ensure the long-term integrity and functionality of bridges and parking decks.

- Q: Can a waterproofing membrane be applied to metal surfaces?

- Metal surfaces can indeed benefit from the application of a waterproofing membrane. These versatile membranes are suitable for use on a range of materials, including metals. Their primary purpose is to safeguard metal surfaces against corrosion and water-related harm. By acting as a barrier, these membranes effectively ward off moisture infiltration, preventing rust and deterioration. Moreover, they can even enhance insulation and bolster the overall durability of the metal surface. To guarantee secure adhesion and enduring protection, it is crucial to select a waterproofing membrane explicitly designed for metal surfaces.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Yes, a waterproofing membrane can definitely be used in schools or educational buildings. Waterproofing membranes are designed to prevent water penetration and protect the building structure from moisture damage. In educational buildings, where a large number of students and staff gather, it is crucial to maintain a safe and healthy environment. Waterproofing membranes can be used in various areas such as basements, roofs, walls, and foundations to prevent water leakage, dampness, and mold growth. By installing a waterproofing membrane, schools can ensure the longevity of their buildings, protect valuable equipment and resources, and provide a comfortable learning environment for students and staff.

Send your message to us

SBS Modified Bitumen Waterproofing Membrane Waterproof Asphalt Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords