Rheem Aluminum Coils - Aluminum Radiator Heating Fins Coil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Radiator Heating Fins Coil Description:

Alloy Aluminium Plate 1200 is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminum Radiator Heating Fins Coil:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

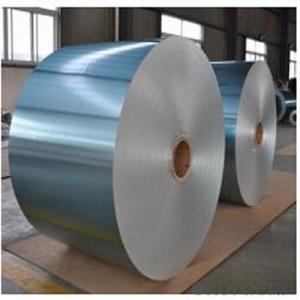

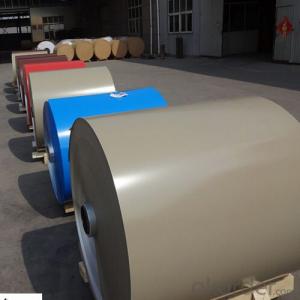

3. Aluminum Radiator Heating Fins Coil Images:

4. Aluminum Radiator Heating Fins Coil Specification:

Product | Code(typical examples) | Spec. mm | Main application | |

Fin stock H16&H14 | Bare fin stock | 3003+1.5%Zn,3003+1.5%Zn+Zr | Thickness: 0.05~0.35mm Width(min):10mm | Auto&Electric RAD. Fins |

Cladding fin stock | core:3003+1.5%Zn Cladding layer(2):4343 | |||

Tube Material (usually H16, H14&H26,H24) | Non-clad tube | 3003 | Thickness:0.2~0.5mm Width:26~200mm | Tube material applied in Auto thermal transfer parts |

Cladding tube material | core:3003 Layer 1(brazing layer):4343 Layer 2(water side):7072 | |||

Header plate,side plate (Temper-O ) | Cladding material | core:3003 Layer 1:4343 Layer 2:4343 | Thickness:1.0~2.5 Width:30~1400 Length:1000~6000 | Auto RAD. header&side platematerial |

Non-clad material | Non-clad 3003 | |||

Collecting tube material (H14 as usual) | core:3003 Cladding layer:4045(single side) | Thickness:1.0~2.0 | Collecting tube of Auto air- conditioner | |

Evaporator tube plate | core:3003 Cladding layer 1: 4343 Cladding layer 2: 4343 | Thickness:0.4~0.6 Width:30~1400 | Laminated evaporator | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What are some common types of aluminum coils used in various industrial applications?

- <p>Yes, there are several types of aluminum coils commonly used in industry. These include: 1) Plain aluminum coils, which are used in packaging and construction. 2) Embossed aluminum coils, utilized for decorative purposes and in the automotive industry. 3) Painted aluminum coils, often used in building materials and appliances. 4) Galvanized aluminum coils, which are corrosion-resistant and used in exterior applications. 5) Heat-treated aluminum coils, known for their strength and used in aerospace and automotive parts. Each type serves specific purposes based on the properties of the aluminum and the coatings or treatments applied.</p>

- Q: What is the difference between pre-painted and natural aluminum coils?

- Pre-painted and natural aluminum coils refer to two different types of aluminum coils used in various industries. The main difference between pre-painted and natural aluminum coils lies in their surface finish. Pre-painted aluminum coils, as the name suggests, are coated with a layer of paint or a protective coating before they are delivered to the customers. This coating is applied in a controlled environment, ensuring a uniform and durable finish. The pre-painted coating provides several advantages such as enhanced corrosion resistance, improved aesthetics, and better weatherability. It also allows for a wide range of color options, making it suitable for architectural applications where color matching is important. On the other hand, natural aluminum coils are left untreated and retain their original metallic appearance. These coils are typically used in applications where the natural aluminum finish is desirable, such as in the manufacturing of consumer electronics, automotive parts, and other industrial products. Natural aluminum coils are known for their excellent thermal conductivity, lightweight nature, and high strength-to-weight ratio. In summary, the difference between pre-painted and natural aluminum coils lies in their surface finish. Pre-painted aluminum coils are coated with a protective layer of paint, offering enhanced corrosion resistance, improved aesthetics, and color options. Natural aluminum coils, on the other hand, retain their original metallic appearance and are often used in applications where the natural aluminum finish is preferred.

- Q: Can aluminum coils be used in the production of window frames?

- Yes, aluminum coils can be used in the production of window frames. Aluminum is a lightweight and durable material that is commonly used in the construction industry for its corrosion resistance and strength. By using aluminum coils, manufacturers can efficiently produce window frames that are long-lasting, energy-efficient, and aesthetically pleasing.

- Q: I've heard many times that it's unhealthy to store or cook food in aluminum, due to leaching, but will this apply to handling aluminum. Also, I heard that most aluminum is coated with a layer of something, to prevent oxidation; is this true?

- aluminum is very biologically unavailable- most forms of aluminium you will come in contact with wont really react with your body. And yes aluminium is actually coated in a thin layer of its own oxide (aluminium oxide) to prevent the entire thing rusting. If it was unsafe to use alot more people would know about it. You are totally fine to grill things in foil and to put foil covered things in the oven!

- Q: Are aluminum coils suitable for low-maintenance applications?

- Yes, aluminum coils are suitable for low-maintenance applications. Aluminum is a durable and corrosion-resistant material, requiring minimal upkeep. It does not rust, is resistant to weathering, and can withstand harsh environments. Additionally, aluminum coils are lightweight and easy to handle, making them a convenient choice for low-maintenance applications.

- Q: Im doing an assignment for science and i need to know the nuclear charge of Aluminium?and also is there a difference between Aluminium and Aluminum or can it just be spelt differently?

- Aluminium is the European spelling Aluminum is the American spelling...just like colour and color. Aluminium ion usually has a 3+ charge

- Q: Are aluminum coils suitable for high-temperature roofing applications?

- No, aluminum coils are not suitable for high-temperature roofing applications. While aluminum is a durable and corrosion-resistant material, it has a relatively low melting point compared to other metals commonly used in roofing, such as steel or copper. Aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), which is much lower than the temperatures that can be reached on a hot roof during summer or in areas with high ambient temperatures. Therefore, using aluminum coils for high-temperature roofing applications could lead to the material warping, distorting, or even melting under the excessive heat, resulting in structural damage and potential leaks. It is advisable to use materials with higher melting points, such as steel or copper, for roofing applications where high temperatures are a concern.

- Q: What are the weight savings achieved by using aluminum coils?

- Using aluminum coils can result in significant weight savings compared to other materials such as steel. Aluminum is a lightweight metal with a density that is approximately one-third that of steel. This means that by using aluminum coils instead of steel coils, the overall weight of a product or structure can be greatly reduced. The weight savings achieved by using aluminum coils can have numerous benefits. In industries such as automotive and aerospace, reducing weight is crucial for improving fuel efficiency and increasing the payload capacity. Lighter vehicles and aircraft require less energy to operate and can carry more passengers or cargo. This leads to cost savings, improved performance, and reduced environmental impact. Additionally, the weight savings achieved by using aluminum coils can also have practical advantages in other applications. For example, in HVAC systems, lighter coils make installation and transportation easier, reducing labor and logistics costs. The specific weight savings achieved by using aluminum coils will vary depending on the application and the design specifications. However, it is generally recognized that aluminum coils offer a significant weight advantage over other materials. The actual weight savings can range from 30% to 70% or more, depending on the specific comparison being made. In summary, the weight savings achieved by using aluminum coils can be considerable. This lightweight material offers numerous advantages in terms of fuel efficiency, payload capacity, performance, and cost savings. When weight reduction is a priority, aluminum coils are an excellent choice for a wide range of industries and applications.

- Q: Can aluminum coils be custom-made to specific requirements?

- Yes, aluminum coils can be custom-made to specific requirements. Aluminum coils are versatile and can be tailored to meet a wide range of specifications and applications. Manufacturers can customize the dimensions, thickness, width, and length of the coil to accommodate specific requirements. Additionally, various surface finishes, such as embossed patterns or coatings, can be applied to enhance the appearance or improve functionality. Customization of aluminum coils allows for precise matching of specific needs in industries such as construction, transportation, aerospace, and many others.

- Q: How can you tell the difference between aluminum and other non-magnetic metals, such as what I've heard called, pot-metal?

- An aluminum bat hits a ball futher than a wooden bat since of the way the wooden bat bends when the ball makes contact, the wooden bat has a sweet spot while the metal one doesn't really have that spot but doesn't break like it's wooden counterpart so the metal bat gives the ball more pop.

Send your message to us

Rheem Aluminum Coils - Aluminum Radiator Heating Fins Coil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords