Heating Up Aluminum Foil

Heating Up Aluminum Foil Related Searches

Heating Aluminum Foil Steaming With Aluminum Foil Heat Sealing Aluminum Foil Heat Resistant Aluminum Foil Cooking Using Aluminum Foil Cooking Aluminum Foil Grilling Aluminum Foil Aluminum Foil Heater Grilling On Aluminum Foil Heat Sealable Aluminum Foil Grilling In Aluminum Foil Cook With Aluminum Foil Boiling Aluminum Foil Grilling Using Aluminum Foil Heat Seal Aluminum Foil Aluminum Foil Grilling Smoking Aluminum Foil Aluminum Foil Heater Plate Aluminum Foil Heat Transfer Melting Aluminum Foil Aluminum Foil Over Heat Vent Hot Aluminum Foil Trick Bake With Aluminum Foil Tricks With Aluminum Foil Baking Aluminum Foil Wrapping With Aluminum Foil Washing Aluminum Foil Combustion Of Aluminum Foil Boil Aluminum Foil Forging Aluminum FoilHeating Up Aluminum Foil Supplier & Manufacturer from China

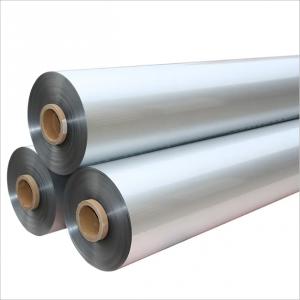

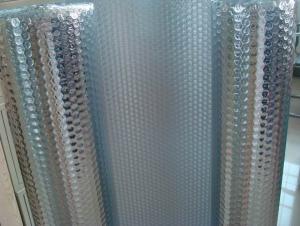

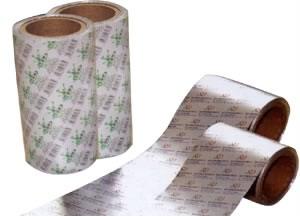

Heating Up Aluminum Foil is a versatile product that is widely used in various industries for its heat insulation and reflective properties. This product is made from high-quality aluminum material, ensuring durability and efficiency in heat retention. It is commonly used in cooking, food packaging, and insulation applications, making it an essential item in both commercial and residential settings.The Heating Up Aluminum Foil is an ideal choice for those looking to maintain optimal temperatures in their cooking and heating processes. Its ability to reflect heat makes it perfect for use in ovens, grills, and other heat-generating appliances. Additionally, it is an excellent option for food packaging, as it helps to keep food warm and fresh during transportation or storage. This product is also utilized in insulation applications, where it helps to reduce heat loss and maintain a comfortable temperature in buildings.

Okorder.com is a reputable wholesale supplier of Heating Up Aluminum Foil, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Heating Up Aluminum Foil they provide meets the highest standards. Their extensive stock allows customers to purchase this product in bulk, making it an attractive option for businesses looking to save on costs and maintain a steady supply of this essential material.

Hot Products