Aluminum Painted Coil - Wholesale Aluminum Coil Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

aluminium coil

good quality

competitive price

short delivery time

long mutual beneficial business cooperation

Detailed informations

1.Alloy:AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011

2.Temper : H12, H14, H16, H18, H22, H24, H26, H32,HO, F

3. Thickness : 0.02mm – 10mm

4. Width : 10mm- 2000mm

5. Standard : ISO9001:2000, SGS , GB/T17748-1999, ASTM, EU standard .

6. Inner diameter : 150mm , 405mm ,500mm 505mm , 508mm

7. Coil weight : 1.5tons – 5.0 tons

8. Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

9. Shipment: By bulk vessel or By container

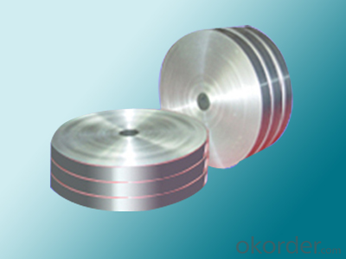

Pictures

Product Description

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

FAQ

1. What is the applications?

Outdoor decoration, business chain, exhibition of advertisement decoration and display ,ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels etc.

2. What is the popular size?

1000*2000,1200*2400,1219*2438,1220*2440

1000*3000,1250*3000,1500*3000 etc.

3. What is the coating?

Polyester, Fluorocarbon, polyurethane and epoxy coating

4. What is the Surface Quality?

be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

5. How about the shipment?

Shipment: By bulk vessel or By container

Welcome to inquiry us! Hope we can establish a long-term relations of cooperation.

- Q: What’s the production standard of aluminum coil?

- GB/T3880-2006 mechanical standard GB/T3190-1996 chemical standard

- Q: Can aluminum coils be used in the production of heat exchangers?

- Indeed, the utilization of aluminum coils in the fabrication of heat exchangers is feasible. Aluminum has gained significant popularity as a preferred material for heat exchangers owing to its exceptional thermal conductivity, which facilitates effective heat transfer. Moreover, its lightweight nature and resistance to corrosion render it a durable and enduring choice for heat exchanger implementations. The incorporation of aluminum coils in heat exchangers is widespread across diverse sectors such as HVAC, refrigeration, automotive, and aerospace.

- Q: What are the different coil slitting widths available for aluminum coils?

- The different coil slitting widths available for aluminum coils can vary depending on the specific requirements and the capabilities of the manufacturer. Generally, aluminum coils can be slit into a wide range of widths, ranging from as narrow as a few millimeters up to several meters wide.

- Q: Can aluminum coils be used in architectural applications?

- Aluminum coils, indeed, find application in architectural projects. The construction industry frequently employs aluminum due to its adaptability, endurance, and ease of manipulation. Architects often make use of aluminum coils for roofing, cladding, and facades, thanks to their malleability in creating diverse forms and proportions. Furthermore, these coils can be coated with various finishes to improve their visual appeal and safeguard against weathering and discoloration. Ultimately, given their blend of utility, attractiveness, and durability, aluminum coils have become a favored option for architectural purposes.

- Q: What is the acceptable range of temperatures for aluminum coils in terms of their functionality and durability?

- <p>The temperature range for aluminum coils can vary depending on the specific application and alloy type. Generally, aluminum coils can operate effectively within a range of -200掳F to 500掳F (-129掳C to 260掳C). For most industrial applications, the working temperature is between -40掳F to 300掳F (-40掳C to 150掳C). However, it's important to consult the manufacturer's specifications for the exact temperature limits of a particular aluminum coil, as these can differ based on the alloy and intended use.</p>

- Q: Can aluminum coils be used in solar energy systems?

- Certainly, solar energy systems can utilize aluminum coils. Aluminum is widely employed in the fabrication of solar panels and solar energy systems owing to its remarkable qualities. Lightweight, durable, and possessing excellent thermal conductivity, aluminum coils are perfect for dispersing heat away from solar cells. Moreover, aluminum's resistance to corrosion is essential for outdoor deployments, where solar panels face diverse weather conditions. By incorporating aluminum coils into solar energy systems, the efficiency and lifespan of the panels are enhanced, thus augmenting the efficacy and sustainability of solar energy generation.

- Q: Can aluminum coils be used for electrical enclosures?

- Electrical enclosures can indeed utilize aluminum coils. Aluminum, being a lightweight and durable substance, boasts exceptional electrical conductivity and heat dissipation capabilities. Furthermore, it exhibits commendable resistance to corrosion, rendering it appropriate for diverse environmental circumstances. Due to its malleability, aluminum coils effortlessly adopt various shapes and sizes, rendering them highly adaptable for enclosure designs. Moreover, aluminum represents a cost-effective alternative when compared to metals such as stainless steel. Nonetheless, it remains crucial to guarantee adequate insulation and grounding to avert any potential electrical hazards when employing aluminum coils in electrical enclosures.

- Q: Can aluminum coils be used in solar energy systems?

- Certainly, solar energy systems can utilize aluminum coils. Aluminum is widely employed in the fabrication of solar panels and solar energy systems owing to its remarkable qualities. Lightweight, durable, and possessing excellent thermal conductivity, aluminum coils are perfect for dispersing heat away from solar cells. Moreover, aluminum's resistance to corrosion is essential for outdoor deployments, where solar panels face diverse weather conditions. By incorporating aluminum coils into solar energy systems, the efficiency and lifespan of the panels are enhanced, thus augmenting the efficacy and sustainability of solar energy generation.

- Q: Can aluminum coils be used for electrical applications?

- Aluminum coils can indeed be utilized for electrical purposes. The electrical industry extensively employs aluminum due to its superb conductivity, lightweight nature, and resistance to corrosion. Various electrical applications, such as transformers, motors, generators, and inductors and solenoids, commonly employ aluminum coils. These coils possess advantages like high thermal conductivity and minimal eddy current losses, which make them highly efficient in the transmission and distribution of electrical power. Moreover, aluminum coils are more cost-effective when compared to copper coils, making them the preferred choice for numerous electrical applications. Nevertheless, it is worth noting that aluminum possesses lower electrical conductivity than copper. Therefore, adjustments in the coil design and dimensions may be necessary to ensure optimal performance.

- Q: This question asks for methods to determine whether an aluminum coil is made from recycled material.

- <p>Determining if an aluminum coil is made from recycled material can be challenging without specific testing, as recycled and virgin aluminum can look identical. However, there are a few indicators: 1) Look for certification or labels on the coil indicating it's made from recycled material. 2) Check with the supplier for documentation or a certificate of analysis that confirms the material's origin. 3) Analyze the coil's composition; recycled aluminum may have slight variations in purity or alloy composition. 4) Use spectrographic analysis to determine the exact composition of the aluminum, which can sometimes reveal if it's recycled. Ultimately, transparency from the supplier is key to confirming the source of the aluminum.</p>

Send your message to us

Aluminum Painted Coil - Wholesale Aluminum Coil Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords