Green Aluminum Coil - Coated and Stucco Embossed Aluminium Coils Alloy 3003

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

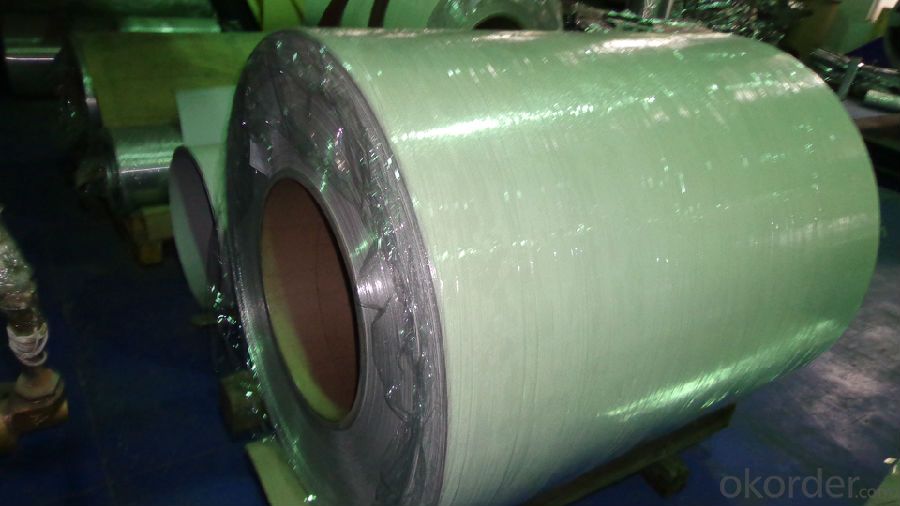

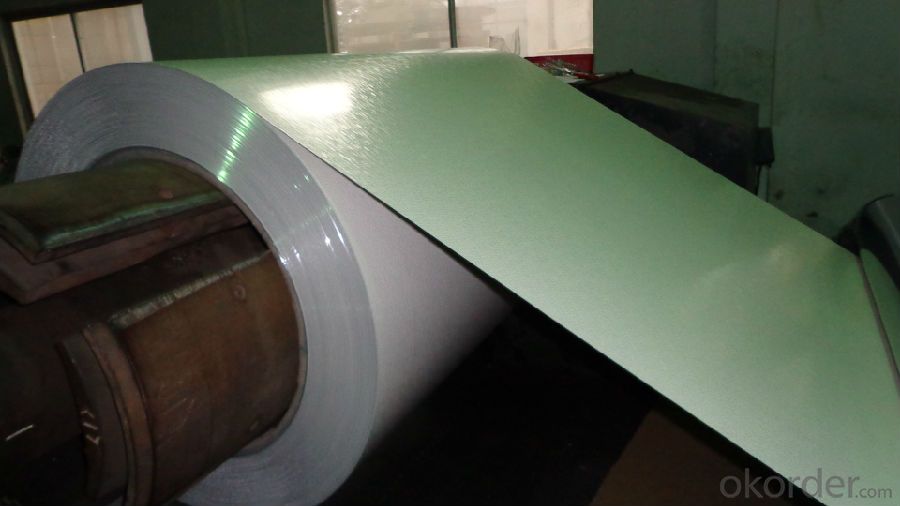

1.Structure of Coated and Stucco Embossed Aluminium Coils Alloy 3003

Alloy 3003, H44 is widely used in cold storages, refrigerators, ice-boxes, etc after being coated and stucco embossed.

We normally use 3003, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of Coated and Stucco Embossed Aluminium Coils 3003

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. Coated and Stucco Embossed Aluminium Coils 3003 Images

4. Specification of Coated and Stucco Embossed Aluminium Coils 3003

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum coils be used in marine or saltwater environments?

- Yes, aluminum coils can be used in marine or saltwater environments. Aluminum is known for its excellent corrosion resistance, making it a suitable material for various marine applications. The oxide layer that naturally forms on the surface of aluminum provides a protective barrier against saltwater and other corrosive elements. This oxide layer can be further enhanced through processes like anodizing or painting, which increases its resistance to corrosion. Additionally, aluminum coils are lightweight, which makes them advantageous for marine applications where weight reduction is desired. Overall, aluminum coils are a popular choice in marine and saltwater environments due to their corrosion resistance and lightweight properties.

- Q: Are aluminum coils suitable for food processing applications?

- Food processing applications can benefit from the use of aluminum coils. Aluminum is a versatile material widely utilized in the food industry for its advantageous properties. It is resistant to corrosion, non-toxic, lightweight, and possesses exceptional thermal conductivity. These qualities make aluminum coils perfect for various food processing tasks like cooking, storage, and transportation. Aluminum coils find their application in the production of cookware, food packaging, and food processing equipment. They are frequently employed in the manufacturing of kitchen utensils such as pots, pans, baking sheets, and more. The remarkable thermal conductivity of aluminum ensures uniform distribution of heat, enabling efficient cooking and eliminating hot spots. Moreover, aluminum coils are commonly utilized in food packaging, including beverage cans and canned foods. Aluminum cans are lightweight, durable, and provide a protective barrier against light, moisture, and air, thus preserving the quality and freshness of the food products. Additionally, aluminum coils are suitable for food processing equipment like heat exchangers, evaporators, and refrigeration systems. The corrosion-resistant nature of aluminum prevents contamination, thereby ensuring the hygiene and safety of the processed food. It is crucial to note that aluminum coils utilized in food processing applications must meet specific food-grade standards to ensure they do not release any harmful substances into the food. These standards are set by regulatory bodies like the Food and Drug Administration (FDA) in the United States and similar organizations globally. Overall, due to their corrosion resistance, non-toxicity, lightweight, and excellent thermal conductivity, aluminum coils are highly suitable for food processing applications. Their extensive usage in the food industry for cooking, packaging, and processing equipment significantly contributes to the safety and efficiency of food production.

- Q: How are aluminum coils used in the production of musical instruments?

- The unique properties and advantages of aluminum coils make them widely used in the production of musical instruments. Guitar pickups are one of the main applications for these coils, as they are wound around a magnetic core and capture the vibrations of the guitar strings, converting them into electrical signals. Aluminum's electromagnetic properties make it an excellent material for this purpose, allowing for precise sensing and amplification of the instrument's sound. Not only are aluminum coils used for guitar pickups, but they are also utilized in the manufacturing of other instruments such as electric keyboards, synthesizers, and electric violins. These coils are crucial for generating and transmitting sound signals, ensuring high-quality audio output. Aluminum's lightweight nature is preferred as it doesn't add unnecessary weight to the instrument, making it easier to handle and more portable. Furthermore, aluminum coils are employed in constructing wind instruments like saxophones and trumpets. They are used to shape the tubing and form the body of these instruments. Aluminum's corrosion resistance is particularly valuable in this application, as it helps maintain the instrument's durability and longevity. In summary, aluminum coils play a vital role in the production of musical instruments by providing a reliable means of capturing, transmitting, and amplifying sound signals. Their unique properties, including electromagnetic sensitivity and corrosion resistance, make them ideal for ensuring high-performance and longevity in various musical instruments.

- Q: I've heard many times that it's unhealthy to store or cook food in aluminum, due to leaching, but will this apply to handling aluminum. Also, I heard that most aluminum is coated with a layer of something, to prevent oxidation; is this true?

- The food thing is true...don't do that If your talking about Aluminum like in can, rods, screws, etc. Your ok...its an alloy. Now If you talking about Lab quality refined pure Al+3... that oxidizes fast enough that you cam see it turn from silver to white before your eyes. I've seen Pure Al stored in oil filled glasses before, but I used it in small cubes that just had to have the outer layer of oxidized stuff shaved off in oxygen free glove boxes. That stuff might dry your hands a bit. So no worries.

- Q: I have been reading up on thermite and the required ingredients. I have extremely fine aluminum powder from a small etch-a-sketch sitting on plastic wrap in my room. On the comments page of the site i got the thermite ingredients from, multiple people said that thermite could explose if you use too fine of a powder. I have also read that powdered aluminum can become very explosive when it is exposed to air or if it becomes damp. Ive gotten particulary worried because the humidity right now is 93%. So, is powdered aluminum too dangerous to have in house and is too fine powdered aluminum explosive when in thermite?

- It is now not aluminum powder; it's ALUM powder, which is one more chemical. Nonetheless, it would not fairly tighten your vagina, despite what some commercials will say. I've not heard of beydary capsules, but I also doubt that they might do anything to fix the predicament either. If a real vaginal shrinking capsule was once on hand, it would be recognized and really trendy, similar to viagra is. Your best wager is to do kegel exercises to fortify and tone your vaginal muscular tissues. These, and nothing else, can help make your vagina tighter.

- Q: How are aluminum coils packaged for transportation?

- Aluminum coils are typically packaged for transportation in a way that ensures their safety and prevents damage. The packaging process involves several steps to ensure that the coils are well-protected during handling, storage, and shipping. Firstly, the aluminum coils are usually wrapped in a protective material such as plastic or paper to safeguard them from dust, moisture, and other external factors. This wrapping helps to maintain the quality and integrity of the coils throughout the transportation process. After wrapping, the coils are then placed onto a pallet or wooden skid. This allows for easy handling with forklifts or other machinery during loading and unloading. The coils are securely strapped to the pallet to prevent any movement or shifting during transportation, minimizing the risk of damage. To provide additional protection, the coils may be placed inside a wooden or metal crate. This crate acts as a further barrier against potential impacts or rough handling that may occur during transit. The crates are carefully designed to fit the size and shape of the aluminum coils, ensuring a snug fit and preventing any unnecessary movement. Furthermore, depending on the specific requirements and distance of transportation, the coils may also be packed inside a shipping container. This offers an additional layer of protection against external elements and provides stability during long-distance transportation. Overall, the packaging process for aluminum coils prioritizes their safety and protection during transportation. The use of protective wrapping, pallets, crates, and shipping containers ensures that the coils arrive at their destination in optimal condition, ready for further processing or usage.

- Q: What are the potential applications of recycled aluminum coils?

- Recycled aluminum coils have a wide range of potential applications due to their numerous beneficial properties. One potential application is in the manufacturing of automotive parts. Aluminum coils can be used to create lightweight body panels, engine components, and structural parts, which can help reduce the overall weight of vehicles, leading to improved fuel efficiency and reduced emissions. Another potential application is in the construction industry. Recycled aluminum coils can be used to make roofing materials, siding, gutters, and window frames. Aluminum is known for its durability, corrosion resistance, and ability to withstand extreme weather conditions, making it an ideal choice for construction purposes. Additionally, recycled aluminum coils can be used in the production of packaging materials. Aluminum is widely used for manufacturing beverage cans, food containers, and foil packaging due to its excellent barrier properties, which help to preserve the freshness and quality of the packaged products. Using recycled aluminum coils for packaging can contribute to reducing the environmental impact associated with the production of new aluminum, as well as reducing waste. Furthermore, recycled aluminum coils can be utilized in the manufacturing of electrical equipment. Aluminum is an excellent conductor of electricity, making it suitable for the production of electrical wires, cables, and other electrical components. Using recycled aluminum coils in the production of electrical equipment can help conserve energy and reduce the need for virgin aluminum extraction and processing. Overall, the potential applications of recycled aluminum coils are vast and diverse, ranging from automotive and construction industries to packaging and electrical equipment. By utilizing recycled aluminum coils, we can achieve both environmental and economic benefits, reducing waste, conserving resources, and promoting sustainability.

- Q: This question asks about the environmental effects associated with the use of aluminum coils.

- <p>The environmental impacts of using aluminum coils include energy consumption during production, potential release of greenhouse gases, and waste generation. Aluminum production requires significant energy, contributing to carbon emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. However, aluminum is highly recyclable, and recycling it saves energy and reduces waste. Proper disposal and recycling practices can mitigate some of these impacts, making aluminum a more sustainable choice when managed correctly.</p>

- Q: Is there aluminum coil of 44mm wide and 0.40mm thick?

- The common width of aluminum coil is 1000mm or 1220mm. If you want 0.4mm*1000MM aluminum coil, you can strip 0.4mm*1000MM aluminum coil.

- Q: How are aluminum coils manufactured to specific dimensions?

- Aluminum coils are manufactured to specific dimensions through a series of processes that involve precision engineering and cutting-edge technology. The process starts with the selection of high-quality aluminum ingots, which are then melted and cast into long, flat strips. Once the aluminum is in the form of flat strips, it undergoes a series of rolling operations. The strips are passed through a rolling mill, where they are progressively reduced in thickness and elongated in length. This rolling process helps in achieving the desired dimensions and thickness for the coils. After the initial rolling, the strips are subjected to a process called annealing. Annealing involves heating the aluminum to a specific temperature and then cooling it slowly. This process helps in improving the ductility and reducing the internal stresses in the metal, making it easier to work with in subsequent manufacturing steps. The next step is slitting, where the wide strip is cut into narrower strips of the desired width. This is done using high-precision slitting machines that ensure accurate and consistent dimensions for each coil. The slitting process also involves edge trimming to remove any irregularities and ensure straight edges. Once the narrower strips are obtained, they are coiled using specialized machines. These machines carefully wind the strips into coils of the desired size and shape. The coiling process ensures that the aluminum is tightly wound and securely held in place. To further enhance the dimensional accuracy, the coils may undergo a final leveling process. This involves passing the coils through a leveling machine that applies pressure to flatten any irregularities or distortions in the metal, ensuring a uniform and consistent thickness. Overall, the manufacturing of aluminum coils to specific dimensions requires a combination of precision rolling, slitting, coiling, and leveling processes. These processes, along with advanced machinery and quality control measures, ensure that the final product meets the exact specifications required by the customer.

Send your message to us

Green Aluminum Coil - Coated and Stucco Embossed Aluminium Coils Alloy 3003

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords