Fiber Cement Board High Quality Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 450 pc

- Supply Capability:

- 4500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cement board is non-asbestos fiber cement product opposed of Portland cement, cellulose fiber and refined sand. Using a special

manufacturing process called autoclave; fiber cement board acquires the strength, durability of cement and easy workability of wood as well as dimensional stability. A non-combustible multi-purpose application fiber cement flat board, fiber cement board comes with various thicknesses which are suitable for various applications: ceiling, wall and floor. It can be used for both exterior and interior applications. Fiber cement board can perfectly be calibrated and then laminated or coated with other materials, such as wood veneer, painting, and steel cover.

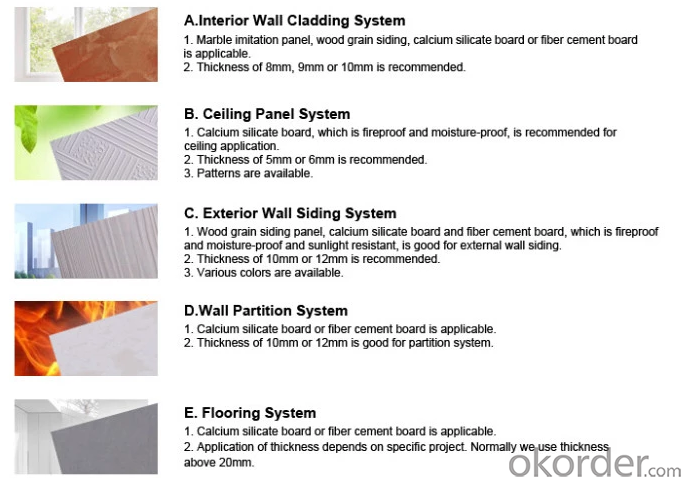

Where can be Fiber Cement Board used for?

Fiber Cement Board is the perfect Choice for building board application such as wall cladding, wall partition and decorative wall. The types of buildings that are suitable for fiber cement board applications are residential, commercial and industrial buildings as well as schools and hospitals, especially where speedy construction, cleanliness and hygiene is of high importance.

Specifications:

1) Dimensions: 1220mm*2440mm

2) Thickness: 4 -30mm

3) Other specifications available

4) Density: 1.1-1.5g/cm3

5) We supply the board with bevel edge in two edges or four edges and square edge

6) Physical properties

A) Bending strength: E 9MPa (in vertical), e7MPa (in paralle)

B) Moisture movement: D0.2%

C) Water content: 10%

D) Thermal conductivity: D0.29W/m. K

E) Continuous anti-freezing: -30oC

F) Anti-high temperature: +120oC

7) Combustibility: Up to the standard of GB 8624, In-combustibility Class A, also up to the standard of BS 476 part 4: 1970, part 6: 1979 and part 7: 1997

Product characteristics:

1) Non toxic

2) Fireproof

3) Soundproof

4) Sawable

5) Thermal insulation

6) Impact resistant

7) Planeable

8)Mothproof

9) Moisture proof

- Q: Is it a decoration material? What's the difference?

- Wood and Miyan cement board is a decoration material, like a large piece of gypsum board, the size is 1220X2440 (MM), wood grain cement board is more delicate, more beautiful rock.

- Q: Production of fiber cement board copy method has what characteristics

- The fibers are oriented in two-dimensional plane orientation, and the direction of the fiber is mainly in the direction of the main stress of the plate. Through other means of subsidies, can make the fiber arrangement direction to meet the requirements of different products.

- Q: I want to put tiles from floor to ceiling in entire bathroom not just the shower area.

- The walls may not be able to hold that much weight.

- Q: Package toilet water pipes, do not want to use red brick (too heavy), want to use lightweight materials, but also want to paste the tiles. Can you elaborate?

- You can use steel keel hanging steel mesh, above the direct wet cement mortar can be posted tiles.

- Q: Span 3 meters of the prefabricated plate can withstand much pressure

- This is generally dare not consider the students, first of all to determine the prefabricated board reinforcement, and then, and structural designers can support the next board support can withstand the maximum force is how much structural design instructions are generally explained, How much is the load, how much live is. The general plant now 350Kg / ㎡, residential office building, then 200Kg / ㎡, but also to the structural designer

- Q: Installing a shower in my basement, and am framing around a fiberglass 36 square shower base. should I put it flush against the frame and then attach cement board (it will overhang) or leave room to slide cement board between base and frame? Thanks!

- The framing goes tight to the shower pan, and the cement board goes down to the lip of the pan, but not over it. IMPORTANT: do not run the cement board over the lip or this will cause a bow at the bottom all the way around. Your tile will run down to the shower base. If you ran the cement board behind the shower pan the lip would stick out and when you tiled, the tile would be pushed out as described at the bottom row. I hope this makes sense to you.

- Q: 60 thick foam cement board Ⅱ how much noise

- Cement foam insulation Due to the formation of numerous porous bubbles, so the sound-absorbing effect than the average concrete about 5 times higher than the sound insulation coefficient is greater than 45dB.

- Q: is there a spray on cement moisture barrier to use under laminate flooring?

- There is no spray on, brush on, or roll on anything that will serve sufficiently as a moisture barrier. You should be painting all concrete floors with cement paint anyway but that is not enough. You need to install a membrane to act as a vapor barrier. It's a good thing anyway because it will make the floor softer to walk on if you're installing the laminate floor directly over the concrete with no sleeper boards.

- Q: Why does the fire burn on the cement board for a long time?

- Cement is a bad bad conductor, prolonged heating will be uneven due to uneven heating caused by uneven expansion, eventually leading to explosion

- Q: I can jump atleast 4 or 5 inches on a rug,grass, mud, sand. but i cant on cement when i ollie on cement my board like slips away after i pop and on everything else it doesnt. help?

- It is cause you have got so used to doing it on carpet. I wouldn't recommend anyone learning tricks stationary on carpet. Just keep practicing it. You will have to relearn it on cement.

Send your message to us

Fiber Cement Board High Quality Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 450 pc

- Supply Capability:

- 4500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords