Insulating Fire Brick GJM Series - Refractory and Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

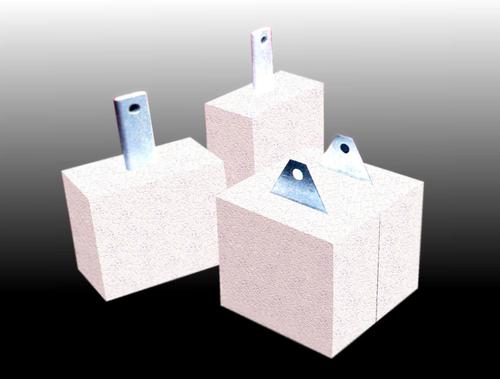

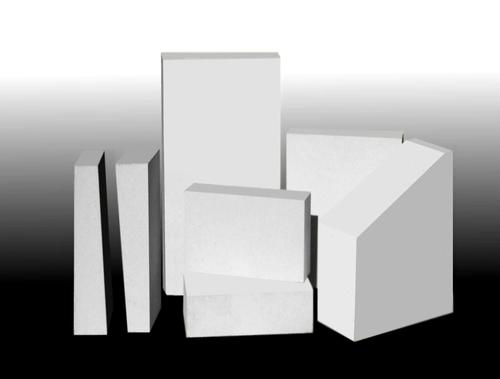

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: What's the difference between refractory bricks and insulating bricks?

- As far as we are concerned about the characteristics of refractory bricks and thermal insulation bricks, refractory bricks are sure to be aimed at fire resistance, while insulating bricks are more focused on thermal insulation. And more specifically, let's take a look at the following parameters.

- Q: Can insulating fire bricks be used in the construction of brick ovens?

- Yes, insulating fire bricks can be used in the construction of brick ovens. Insulating fire bricks are specifically designed to have high thermal insulation properties, making them ideal for applications where heat retention is crucial, such as in brick ovens. These bricks are made from lightweight refractory materials and have a lower density compared to regular clay bricks, which helps to minimize heat loss and improve energy efficiency. When building a brick oven, it is important to consider the insulation layer that will help retain heat and distribute it evenly throughout the oven. Insulating fire bricks can be used to create this insulation layer, which is typically placed between the inner cooking chamber and the outer layer of the oven. These bricks will help to minimize heat transfer to the outer layer, preventing excessive heat loss and ensuring that the oven reaches and maintains the desired high temperatures for baking or cooking. In addition to their excellent thermal insulation properties, insulating fire bricks also have high resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is particularly important in brick ovens, as they often experience significant temperature variations during the baking process. Overall, insulating fire bricks are a suitable and recommended choice for the construction of brick ovens due to their thermal insulation properties, lightweight nature, and resistance to thermal shock. Using these bricks will help to create a well-insulated and efficient oven that can achieve and maintain high temperatures for optimal baking or cooking results.

- Q: Can insulating fire bricks be used in the construction of thermal insulation roofs?

- Insulating fire bricks are indeed applicable in the construction of thermal insulation roofs. Their design is tailored to possess exceptional thermal insulation characteristics, rendering them a perfect option for heat retention and energy efficiency needs. These bricks are crafted from lightweight materials like clay, which exhibit low thermal conductivity and remarkable resistance to heat transfer. Consequently, they effectively minimize heat loss or gain, making them suitable for thermal insulation roofs. Moreover, insulating fire bricks showcase durability and the ability to endure high temperatures, establishing them as a dependable choice for long-lasting utilization in roofing applications.

- Q: Are insulating fire bricks resistant to flame penetration?

- Yes, insulating fire bricks are resistant to flame penetration. Insulating fire bricks are made from materials that have high melting points and excellent thermal insulation properties. They are designed to withstand high temperatures and can resist flame penetration. These bricks are often used in applications where there is a need for insulation and protection against heat, such as in furnaces, kilns, and fireplaces. The composition and structure of insulating fire bricks make them highly resistant to flame penetration, allowing them to effectively contain and control the spread of fire.

- Q: Is it possible to recycle used insulating fire bricks?

- Yes, it is possible to recycle used insulating fire bricks. These bricks can be crushed, ground, or shredded, and then the resulting material can be used as a raw material in the production of new bricks or as an aggregate in construction materials. Recycling used insulating fire bricks helps to reduce waste and conserve resources.

- Q: Can insulating fire bricks be used for insulation in furnaces?

- Indeed, insulation in furnaces can be achieved by utilizing insulating fire bricks. Constructed from lightweight materials like clay and minerals, these bricks possess exceptional thermal insulation characteristics. Specifically designed to endure intense temperatures, they are well-suited for furnace applications. By impeding heat leakage from the furnace, these bricks aid in diminishing heat loss and heightening energy efficiency. Furthermore, insulating fire bricks serve to safeguard the furnace's external structure from excessive heat, thereby prolonging its lifespan. All in all, when it comes to insulation in furnaces, insulating fire bricks are a dependable and efficient option.

- Q: Are insulating fire bricks resistant to cracking?

- Insulating fire bricks are specifically designed to have a high resistance to cracking. They are made from lightweight ceramic materials that have low thermal conductivity and high thermal shock resistance. These properties enable the bricks to withstand rapid temperature changes without cracking. Additionally, insulating fire bricks undergo a firing process that strengthens their structure and minimizes the risk of cracking. However, it is important to note that extreme thermal shock or physical impact can still potentially cause cracking in insulating fire bricks, so proper handling and installation techniques should be followed to ensure their longevity and effectiveness.

- Q: Do insulating fire bricks have a high thermal shock resistance?

- Yes, insulating fire bricks typically have a high thermal shock resistance. These bricks are specifically designed to withstand rapid changes in temperature without cracking or breaking. They are made from lightweight refractory materials that have low thermal conductivity, which helps to minimize heat transfer and prevent thermal stress. Additionally, insulating fire bricks often go through a firing process that further enhances their thermal shock resistance. Overall, these bricks are well-suited for applications where they are exposed to extreme temperature fluctuations, making them a reliable choice for insulation in high-temperature environments.

- Q: Do insulating fire bricks have a high heat storage capacity?

- Insulating fire bricks possess a remarkable capacity for storing heat. These bricks are engineered to possess minimal thermal conductivity, enabling them to preserve heat for extended durations. Consequently, they are extremely well-suited for scenarios that demand heat retention, such as within furnaces, kilns, and other settings with elevated temperatures. The impressive heat storage capacity of insulating fire bricks facilitates effective heat preservation and dispersion, ultimately enhancing energy efficiency and lessening heat dissipation.

- Q: Can insulating fire bricks be used in pizza ovens or outdoor grills?

- Indeed, insulating fire bricks are perfectly suitable for utilization in pizza ovens or outdoor grills. These bricks are specifically designed to withstand elevated temperatures and offer exceptional insulation properties, rendering them highly desirable for applications that demand intense heat, such as pizza ovens or grills. By incorporating insulating fire bricks, one can guarantee even distribution and retention of heat within the cooking area, resulting in a more efficient cooking process and delectable food. Furthermore, these bricks possess remarkable durability and resistance to thermal shock, allowing them to endure repeated exposure to extreme temperatures without cracking or deteriorating. Consequently, opting to use insulating fire bricks in pizza ovens or outdoor grills represents a superb choice for achieving optimal heat retention and superior cooking performance.

Send your message to us

Insulating Fire Brick GJM Series - Refractory and Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords