Insulation Bricks Or Insulation Fire Brick High Quality 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

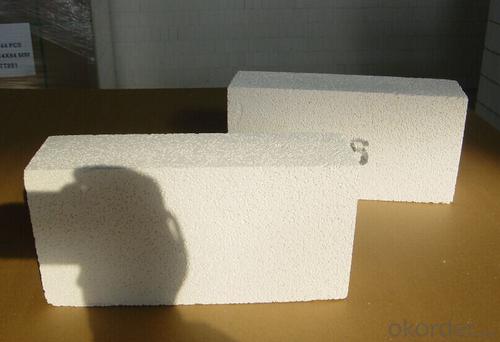

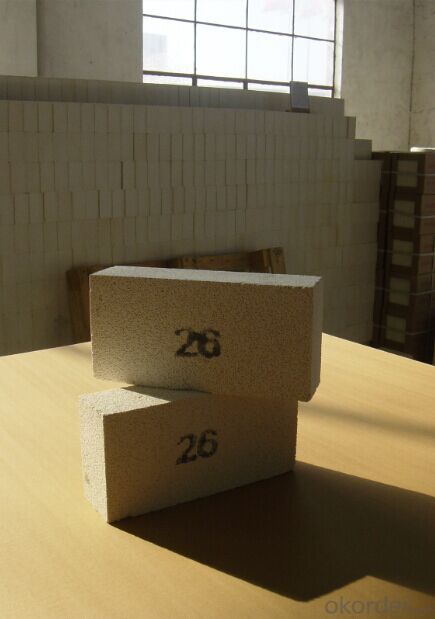

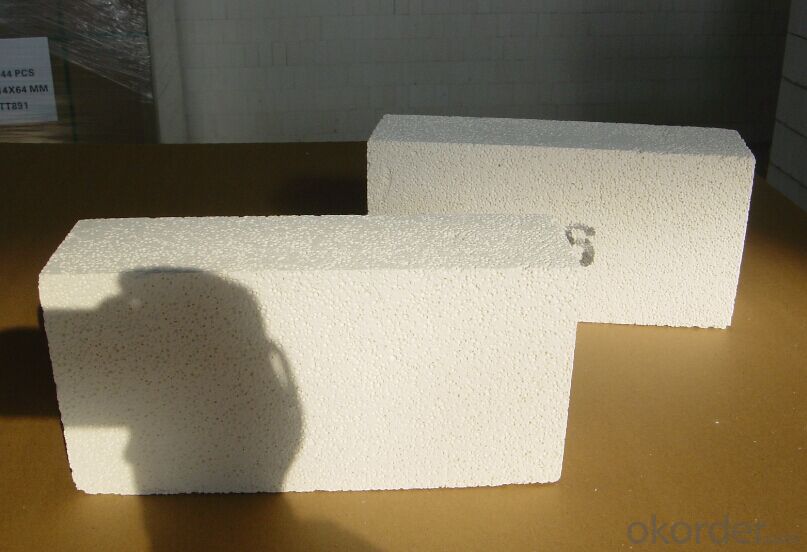

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are insulating fire bricks resistant to carbon dioxide?

- Yes, insulating fire bricks are resistant to carbon dioxide.

- Q: What are the common sizes of insulating fire bricks?

- Insulating fire bricks, also known as IFBs, are widely used in various high-temperature applications due to their excellent thermal insulation properties. These bricks are available in different sizes to suit different industrial needs. The common sizes of insulating fire bricks are typically classified based on their dimensions, such as length, width, and thickness. The most common sizes range from 9" x 4.5" x 2.5" (230mm x 115mm x 65mm) to 9" x 4.5" x 3" (230mm x 115mm x 75mm). These sizes are often referred to as standard or regular size IFBs. Apart from the regular sizes, insulating fire bricks can also be found in larger or smaller dimensions to meet specific requirements. For instance, larger IFBs may measure around 12" x 6" x 4" (305mm x 152mm x 102mm), while smaller ones can be as compact as 6" x 4" x 2" (152mm x 102mm x 51mm). It is important to note that the availability of specific sizes may vary depending on the manufacturer or supplier. Some companies may offer customized sizes to cater to the unique needs of their customers. Additionally, the thickness of insulating fire bricks can also vary, with options ranging from 2" (51mm) to 4" (102mm) and beyond. When selecting the appropriate size of insulating fire bricks, it's crucial to consider factors such as the desired insulation properties, operating temperature, and the specific application requirements. Consulting with an expert or referring to manufacturer specifications can help ensure the correct size is chosen for optimal performance and efficiency.

- Q: What is the typical flexural strength of an insulating fire brick?

- The typical flexural strength of an insulating fire brick can vary depending on the specific composition and manufacturing process. However, on average, insulating fire bricks have a flexural strength range of 1-10 megapascals (MPa).

- Q: Are insulating fire bricks resistant to mold or mildew growth?

- No, insulating fire bricks are not naturally resistant to mold or mildew growth.

- Q: What sizes are insulating fire bricks available in?

- Insulating fire bricks are available in various sizes, including standard sizes like 9" x 4.5" x 2.5" and 9" x 4.5" x 3". However, custom sizes can also be manufactured to meet specific requirements.

- Q: Are insulating fire bricks resistant to acid attack?

- Yes, insulating fire bricks are resistant to acid attack.

- Q: What is the typical open porosity of an insulating fire brick?

- The typical open porosity of an insulating fire brick is around 50-70%.

- Q: Can insulating fire bricks be used in lime plants?

- Yes, insulating fire bricks can be used in lime plants. Insulating fire bricks are specially designed to have low thermal conductivity, which means they are excellent at preventing heat transfer. In lime plants, where high temperatures are required for the calcination process, insulating fire bricks can be used to line the kilns and other high-temperature areas. These bricks help to retain the heat within the lime kilns, reducing energy loss and improving overall efficiency. Additionally, insulating fire bricks are resistant to chemical attacks and can withstand the harsh conditions in lime plants, making them a suitable choice for this application.

- Q: Are insulating fire bricks suitable for use in aluminum smelting furnaces?

- Yes, insulating fire bricks are suitable for use in aluminum smelting furnaces. They have excellent thermal insulation properties, high temperature resistance, and can withstand the harsh conditions of aluminum smelting. Additionally, their low thermal conductivity helps to reduce energy consumption and increase furnace efficiency.

- Q: Are insulating fire bricks suitable for use in the construction of smelters?

- Yes, insulating fire bricks are suitable for use in the construction of smelters. These bricks are designed to withstand high temperatures and provide excellent insulation properties, making them ideal for lining the walls and floors of smelters. They help to retain heat, reduce energy loss, and protect the structure from extreme heat. Additionally, insulating fire bricks are lightweight and easy to install, making them a preferred choice for smelter construction.

Send your message to us

Insulation Bricks Or Insulation Fire Brick High Quality 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords