High Quality Insulating Fire Brick - Insulation Bricks Refractory 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

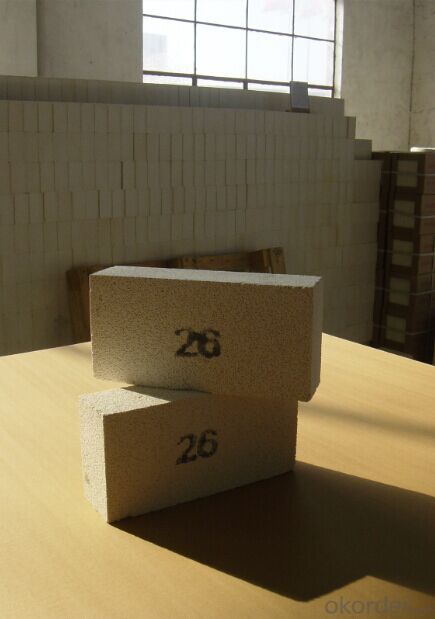

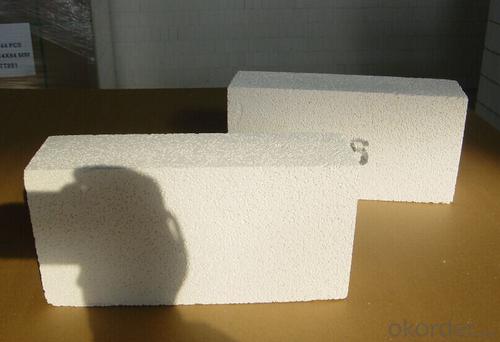

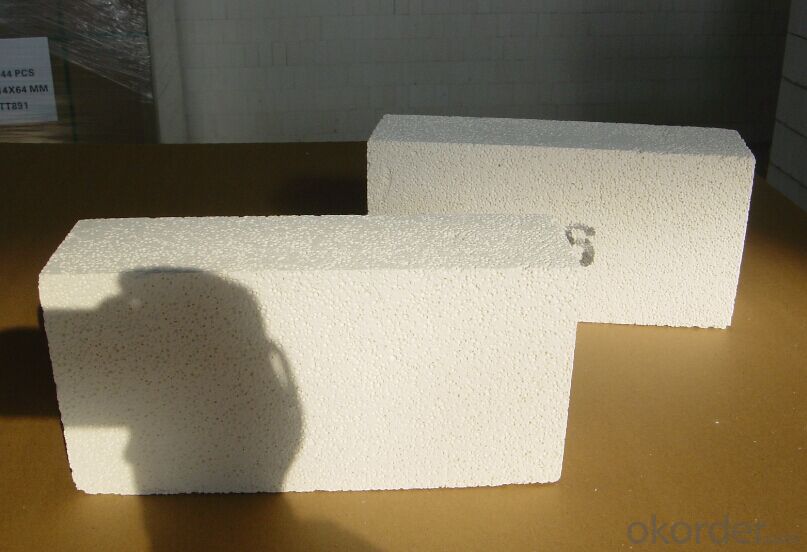

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can insulating fire bricks be used in solar power plants?

- Yes, insulating fire bricks can be used in solar power plants. They are commonly used in the construction of high-temperature equipment such as solar receivers, combustion chambers, and thermal energy storage systems. Insulating fire bricks help to minimize heat loss and maintain high operating temperatures, making them suitable for various applications in solar power plants.

- Q: Can insulating fire bricks be used in refractory coatings?

- Yes, insulating fire bricks can be used in refractory coatings. They provide excellent thermal insulation properties and can help in maintaining high temperatures while minimizing heat loss.

- Q: Do insulating fire bricks require any special firebrick mortar for installation?

- Indeed, the installation of insulating fire bricks necessitates the utilization of a specialized firebrick mortar. Regular mortar is unsuitable due to its inability to furnish the essential thermal insulation characteristics or endure the elevated temperatures for which these bricks are intended. Insulating firebrick mortar is purposefully engineered to withstand extreme temperatures and effectively adhere to insulating fire bricks. Typically, this mortar is concocted from an amalgamation of refractory materials, including high-alumina cement, silica sand, and fire clay. Employing the appropriate firebrick mortar is imperative to guarantee a robust and long-lasting installation of insulating fire bricks.

- Q: What is the typical weight of an insulating fire brick?

- The typical weight of an insulating fire brick can vary depending on the specific type and manufacturer. However, on average, an insulating fire brick weighs between 2.5 to 3.5 pounds (1.1 to 1.6 kilograms). It is important to note that this weight estimation is for a standard-sized brick, typically measuring 9 x 4.5 x 2.5 inches (22.9 x 11.4 x 6.4 centimeters). Different densities and compositions of insulating fire bricks can result in slight variations in weight, so it is always advisable to refer to the manufacturer's specifications for accurate information.

- Q: Do insulating fire bricks require a protective coating for outdoor use?

- Insulating fire bricks have been specifically engineered to endure high temperatures and offer thermal insulation. While they are commonly applied indoors, such as in kilns, furnaces, and fireplaces, they can also be utilized outside. However, the necessity of a protective coating for outdoor use relies on the specific circumstances and environment in which they will be employed. Generally, insulating fire bricks are composed of materials like clay or alumina silicate, which possess inherent resistance to weathering and environmental factors. They can tolerate exposure to rain, snow, and even extreme temperatures without significant deterioration. These bricks are often classified as refractory materials due to their heat resistance, rendering them highly durable in outdoor settings. Nonetheless, there may be instances where it is advisable to apply a protective coating to the insulating fire bricks for additional protection. For example, if the bricks will be continually exposed to harsh weather conditions, prolonged UV radiation, or corrosive substances, a protective coating can enhance their longevity. The selection of coating will depend on the specific requirements and anticipated conditions. Various options are available, such as high-temperature paint, ceramic coatings, or silicone-based sealants. These coatings can furnish an additional layer of safeguarding against moisture, chemicals, and temperature fluctuations, ensuring the bricks retain their insulation properties and structural integrity over time. In conclusion, insulating fire bricks are generally suitable for outdoor use without necessitating a protective coating, as they are specifically designed to withstand high temperatures and adverse weather conditions. However, if the bricks will be exposed to particularly harsh or corrosive environments, applying an appropriate protective coating can offer additional durability and ensure their longevity. It is always recommended to seek guidance from experts or manufacturers for specific advice based on the intended use and outdoor conditions.

- Q: How do insulating fire bricks compare to other refractory materials?

- Insulating fire bricks have a lower thermal conductivity compared to other refractory materials, making them more effective in preventing heat loss. They are also lightweight and have good insulation properties, making them suitable for applications where thermal insulation is crucial. However, they may have lower mechanical strength and higher porosity compared to other refractory materials, limiting their use in certain high-temperature and high-pressure environments.

- Q: What are the types of building blocks?

- Ordinary housing: building brick (clay brick), and non sintered brick (sand lime brick, fly ash brick, cement brick, etc.)

- Q: What is the typical bulk density of an insulating fire brick?

- The typical bulk density of an insulating fire brick is around 0.6 to 1.2 grams per cubic centimeter (g/cm³).

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

- Q: Are insulating fire bricks resistant to flame spread?

- Yes, insulating fire bricks are highly resistant to flame spread. These bricks are specifically designed to withstand high temperatures and effectively contain and insulate heat. They are made from refractory materials that have low thermal conductivity, which means they are excellent at preventing heat transfer and resisting flame spread. Insulating fire bricks are commonly used in applications such as kilns, furnaces, and fireplaces, where the ability to withstand and control high temperatures is crucial. Their resistance to flame spread makes them a reliable and safe choice for these types of environments.

Send your message to us

High Quality Insulating Fire Brick - Insulation Bricks Refractory 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords