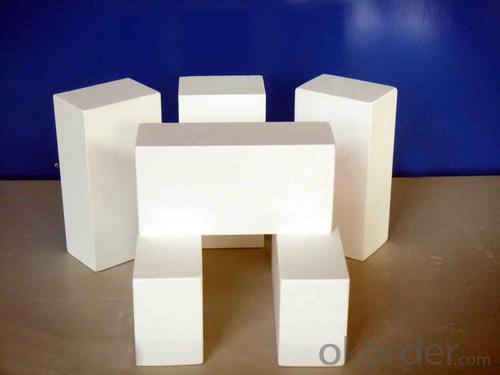

Insulating Fire Brick - High Temperature Bubble Alumina Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bubble Alumina Brick and Insulating Firebrick are high temperature refractory brick, max temp 1800 deg C, used in furnace kiln.

Bubble Alumina Brick and Insulating Firebrick are high temperature refractory brick.

Bubble Alumina Brick. We stock in both 2.5 & 3” sizes. We also carry double bump interlocking anchor styles. For use up to 1800C, these brick have excellent insulating properties as well as high hot strengths.

Insulating firebrick, we carry produces thirteen types of Insulating Fire Brick for use in applications from 2,000°F (1,093°C) to 3,200°F (1,760°C). Each type is formulated to meet specific thermal and physical requirements and after firing is machined to precise tolerances.

Made from high purity refractory clays and other ceramic raw materials, these insulating fire brick contain a carefully graded organic filler which is burned out during manufacture to give a uniform controlled pore structure.

Advantages of bubble alumina brick.

High Insulating Va

The high compressive strength of bubble alumina brick allows for self-supporting structures at elevated temperatures. Insulating fire brick are compatible with dense fire brick and add strength to the whole construction.

Low Heat Storage

Lower heat storage versus dense brick means reduced fuel costs in cyclically operated heating equipment. lue

The light weight and high insulating value of refractory brick make possible thinner furnace walls, improved efficiency and lower operating costs.

Strong

The high compressive strength of bubble alumina brick allows for self-supporting structures at elevated temperatures. Insulating fire brick are compatible with dense fire brick and add strength to the whole construction.

Low Heat Storage

Lower heat storage versus dense brick means reduced fuel costs in cyclically operated heating equipment.

Application

DJM 26 Light Weight Insulating fire brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Are insulating fire bricks resistant to chemical attack?

- Yes, insulating fire bricks are generally resistant to chemical attack. These bricks are made from high-purity refractory materials, such as alumina or silica, which have excellent chemical stability. They are designed to withstand high temperatures and are thus highly resistant to the corrosive effects of chemicals. However, it is important to note that the degree of chemical resistance can vary depending on the specific composition of the insulating fire brick and the type of chemical being used. In some cases, certain aggressive chemicals may still cause some degree of degradation or erosion over time. Therefore, it is always recommended to consult the manufacturer or supplier for specific information regarding the chemical resistance of insulating fire bricks in relation to the intended application.

- Q: Are insulating fire bricks resistant to molten salts?

- Insulating fire bricks are known for their general resistance to molten salts. These bricks are specifically designed to endure high temperatures and provide excellent thermal insulation. They are typically crafted from special refractory materials with a high melting point and chemical inertness. In contrast, molten salts have a corrosive nature that can cause harm to various materials. Nevertheless, insulating fire bricks can endure the corrosive effects of molten salts due to their distinctive composition. Their dense structure and superior refractory properties enable them to resist the corrosive impact of molten salts over extended periods. Moreover, insulating fire bricks find widespread use in industries like metal smelting, glass manufacturing, and chemical processing, where encounters with molten salts are common. Their resistance to molten salts makes them highly suitable for applications involving these corrosive substances. However, it is important to note that the specific resistance of insulating fire bricks to molten salts can vary depending on the brick's composition and the type of molten salt used. Therefore, it is recommended to consult the manufacturer or a refractory materials specialist to ensure the appropriateness of insulating fire bricks for a particular application involving molten salts.

- Q: What are the advantages of using insulating fire bricks over other insulation materials?

- Insulating fire bricks offer numerous benefits compared to other insulation materials. To begin with, their high thermal conductivity effectively prevents heat transfer, making them ideal for applications where heat containment is crucial, such as furnaces, kilns, and industrial ovens. Their ability to withstand high temperatures and prevent heat loss makes them a reliable insulation option. Furthermore, insulating fire bricks are extremely durable and resistant to wear and tear. They are constructed with high-quality refractory materials designed to withstand extreme conditions like thermal shocks and chemical exposure. This durability ensures a longer lifespan and reduces the need for frequent replacements or repairs. Another advantage lies in their versatility. Insulating fire bricks come in various shapes and sizes, allowing for easy customization and installation in different applications. They can be effortlessly cut or shaped to fit specific requirements, making them suitable for complex geometries or curved surfaces. This flexibility allows for efficient insulation in a wide range of settings. Moreover, insulating fire bricks possess excellent insulation properties even at lower densities. This means they can provide optimal thermal insulation while also reducing the overall weight of the structure. This is particularly advantageous in industries where weight reduction plays a critical role, such as aerospace or automotive manufacturing. Lastly, insulating fire bricks are environmentally friendly. They are typically manufactured using natural and recyclable materials, minimizing their impact on the environment. Additionally, their long lifespan and low maintenance requirements contribute to sustainability by reducing waste generation and energy consumption. In conclusion, the advantages of utilizing insulating fire bricks over other insulation materials encompass high thermal conductivity, durability, versatility, lightweight design, and environmental friendliness. These characteristics establish them as the preferred choice for insulation in various industries and applications.

- Q: Can insulating fire bricks be used in the construction of pottery molds?

- Yes, insulating fire bricks can be used in the construction of pottery molds. Insulating fire bricks are made from lightweight refractory materials that have excellent heat insulation properties. These bricks are specifically designed for applications that require high temperatures, such as pottery kilns. When constructing pottery molds, it is important to have materials that can withstand the intense heat of the kiln. Insulating fire bricks can withstand temperatures up to 3000°F (1650°C), making them suitable for pottery mold construction. They provide insulation to prevent heat loss and maintain consistent temperatures inside the kiln, which is essential for achieving the desired firing results. Furthermore, insulating fire bricks can be easily shaped and cut to fit the desired mold design. They are also lightweight, which makes them easier to handle during the mold construction process. Additionally, the insulating properties of these bricks help to reduce energy consumption by preventing excessive heat loss, making them cost-effective in the long run. Overall, insulating fire bricks are a suitable choice for constructing pottery molds due to their ability to withstand high temperatures, provide insulation, and be easily shaped to fit specific designs.

- Q: Are insulating fire bricks suitable for insulation in cryogenic applications?

- Yes, insulating fire bricks are suitable for insulation in cryogenic applications. Insulating fire bricks have excellent thermal insulation properties, low thermal conductivity, and can withstand extremely low temperatures. This makes them ideal for use in cryogenic applications where insulation is required to maintain the low temperature of the system.

- Q: Can insulating fire bricks be used for insulation in oil refineries?

- Indeed, insulating fire bricks are a suitable choice for insulation in oil refineries. These bricks are specifically engineered to endure extreme temperatures and offer exceptional thermal insulation. Crafted from lightweight refractory materials with minimal thermal conductivity, they effectively curtail heat transfer. Consequently, insulating fire bricks find utility in insulating diverse refinery elements such as furnaces, reactors, and pipelines, where elevated temperatures and heat transfer prevail. By incorporating these bricks, oil refineries can substantially diminish heat loss, thereby enhancing energy efficiency and trimming operational expenses.

- Q: Are insulating fire bricks suitable for use in residential fireplaces?

- Insulating fire bricks can be suitable for use in residential fireplaces, depending on the specific requirements and preferences of the homeowner. Insulating fire bricks are designed to have a low thermal conductivity, which means they can effectively retain heat and prevent it from escaping the fireplace. This can result in a more efficient and effective heating of the room, as less heat is lost through the bricks. Additionally, insulating fire bricks are lightweight and easy to handle, making them a convenient option for homeowners who may want to install or replace bricks themselves. They are also durable and resistant to high temperatures, ensuring that they can withstand the intense heat produced by the fire. However, it is important to note that insulating fire bricks may not be the best choice for everyone. Traditional fire bricks are denser and have a higher thermal mass, which means they can absorb and radiate heat for a longer period of time. This can create a more consistent and long-lasting heat output, which some homeowners may prefer. Ultimately, the decision to use insulating fire bricks in a residential fireplace should be based on the specific needs and preferences of the homeowner. Consulting with a professional fireplace installer or seeking advice from a reputable supplier can help ensure that the chosen bricks are suitable for the intended use.

- Q: Can insulating fire bricks reduce heating or cooling costs?

- Insulating fire bricks possess the ability to decrease heating or cooling expenses. These bricks are specially designed to exhibit a high level of thermal insulation, meaning they possess low thermal conductivity and can effectively hinder the transfer of heat between a building's interior and exterior. In the construction of fireplaces, ovens, or kilns, the utilization of insulating fire bricks aids in retaining heat within these structures. This enables them to achieve and maintain higher temperatures while consuming less energy. Consequently, this leads to substantial savings on heating costs, as the desired temperature can be achieved with reduced energy usage. Similarly, when employed in the construction of walls, insulating fire bricks serve to minimize heat transfer between a building's inside and outside. This results in decreased heating or cooling requirements, as the insulation helps to maintain a consistent indoor temperature. Subsequently, less energy is needed to heat or cool the building, resulting in lower energy bills and reduced overall heating or cooling expenses. It should be noted that the effectiveness of insulating fire bricks in reducing heating or cooling costs can vary based on factors such as overall building insulation, structure size and design, and climate conditions. Nevertheless, in general, the utilization of insulating fire bricks can contribute to energy efficiency and cost savings in heating or cooling systems.

- Q: Can insulating fire bricks be used in glass furnaces?

- Glass furnaces can indeed utilize insulating fire bricks. These bricks are specifically engineered with low thermal conductivity, rendering them ideal for high-temperature environments such as glass furnaces. The implementation of these bricks aids in the reduction of heat loss from the furnace, consequently enhancing energy efficiency and decreasing operational expenses. Moreover, they offer superior insulation and aid in maintaining consistent temperatures within the furnace, a vital factor in glass production. Furthermore, insulating fire bricks exhibit excellent resistance to thermal shock and can endure the extreme temperatures and rapid temperature fluctuations that are common in glass furnaces. Overall, integrating insulating fire bricks into glass furnaces can result in enhanced furnace performance, heightened productivity, and energy conservation.

- Q: Can insulating fire bricks be used in the construction of lime production kilns?

- Yes, insulating fire bricks can be used in the construction of lime production kilns. Insulating fire bricks are designed to have excellent thermal insulation properties, which makes them suitable for high-temperature applications like lime production kilns. They can help in maintaining the desired temperature inside the kilns and reducing heat loss, enhancing the efficiency and productivity of the lime production process.

Send your message to us

Insulating Fire Brick - High Temperature Bubble Alumina Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords