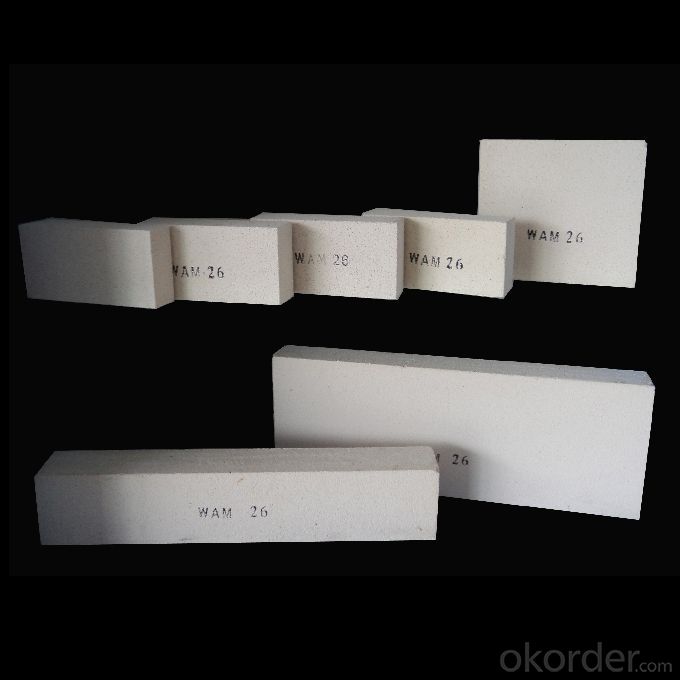

Insulating Fire Brick - Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: How do insulating fire bricks help reduce fuel consumption?

- Efficient insulation in high-temperature environments is facilitated by insulating fire bricks, resulting in reduced fuel consumption. These bricks are composed of lightweight materials that possess high thermal resistance, enabling them to retain heat and prevent its dissipation. Through the reduction of heat loss, insulating fire bricks establish an energy-efficient setting that necessitates less fuel to sustain the desired temperature. Furthermore, the insulating properties of these bricks facilitate the even distribution of heat, curtailing the need for excessive fuel consumption to rectify uneven heating. Ultimately, the utilization of insulating fire bricks conserves fuel and diminishes energy wastage across a range of industrial applications, including kilns, furnaces, and ovens.

- Q: Can insulating fire bricks be used in high-temperature insulation boards?

- Yes, insulating fire bricks can be used in high-temperature insulation boards. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. They can be easily incorporated into insulation boards to enhance their insulating properties and increase their resistance to heat.

- Q: Can insulating fire bricks be used in the construction of furnaces?

- Yes, insulating fire bricks can be used in the construction of furnaces. Insulating fire bricks are specially designed bricks that have high insulating properties, allowing them to withstand high temperatures while minimizing heat loss. These bricks are made from lightweight materials such as clay, silica, and alumina. They have a low thermal conductivity, which means they can effectively maintain heat within the furnace while preventing the outer surface from becoming too hot. This makes them ideal for lining the walls, roof, and floor of furnaces, helping to increase energy efficiency and reduce fuel consumption. Additionally, insulating fire bricks are resistant to thermal shock, making them highly durable and long-lasting in the harsh conditions of a furnace. Overall, insulating fire bricks are a popular choice for furnace construction due to their excellent insulating properties and ability to withstand high temperatures.

- Q: Do insulating fire bricks have good mechanical strength?

- Insulating fire bricks generally have moderate mechanical strength compared to regular fire bricks. While their main purpose is to provide excellent thermal insulation, they are still able to withstand some amount of mechanical stress. However, it is important to note that their mechanical strength may not be as high as other types of fire bricks, which are specifically designed to withstand heavier loads and abrasion. Therefore, if the application requires both high insulation and superior mechanical strength, it might be necessary to consider using a combination of insulating fire bricks and regular fire bricks to achieve the desired outcome.

- Q: Can insulating fire bricks be used for insulation in hot water tanks?

- Yes, insulating fire bricks can be used for insulation in hot water tanks. Insulating fire bricks are designed to have excellent thermal insulation properties, making them an ideal choice for insulating hot water tanks. These bricks can effectively prevent heat loss from the hot water tank, helping to maintain the temperature of the water for longer periods of time. Additionally, insulating fire bricks are highly durable and can withstand high temperatures without cracking or breaking, making them a reliable choice for hot water tank insulation.

- Q: Are insulating fire bricks resistant to moisture absorption?

- Indeed, insulating fire bricks exhibit resistance to moisture absorption. These bricks have been meticulously engineered to possess a low porosity, thereby thwarting any moisture absorption. The manufacturing procedure entails the utilization of top-notch refractory materials that possess the capability to endure extreme temperatures, while simultaneously resisting the detrimental impact of moisture. Consequently, insulating fire bricks emerge as an exemplary option for scenarios necessitating moisture resistance, such as kilns, furnaces, and other environments characterized by elevated temperatures.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber-lined kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic fiber-lined kilns. Insulating fire bricks are specifically designed to provide high levels of insulation, making them ideal for applications where heat retention is important. When used in conjunction with ceramic fiber lining, insulating fire bricks can help increase energy efficiency and reduce heat loss in kilns. Additionally, insulating fire bricks are lightweight and easy to work with, allowing for easier installation and construction of the kiln. Overall, using insulating fire bricks in the construction of ceramic fiber-lined kilns can help improve the kiln's performance and efficiency.

- Q: Do insulating fire bricks affect the overall aesthetics of a structure?

- Insulating fire bricks do not significantly impact the overall aesthetics of a structure since they are typically hidden within the walls or used in areas where their appearance is not prominently visible.

- Q: Are there any differences between insulating bricks and refractory bricks?

- The insulation performance of thermal conductivity of insulating brick in general 0.2-0.4 (average temperature 350 - 25 DEG C) w/m.k, and the thermal conductivity of refractory brick in 1 (the average temperature of 350 - 25 DEG C) above w/m.k, which can obtain the insulation performance of insulating brick than refractory brick insulation performance is much better.

- Q: Can insulating fire bricks be used in a refractory lining?

- Indeed, refractory linings can incorporate insulating fire bricks. These bricks are purposefully crafted to offer thermal insulation and minimize heat dissipation in scenarios involving high temperatures. Possessing low thermal conductivity and exceptional insulating properties, they are perfectly suited for use in refractory linings. By curbing heat transfer to the surrounding environment, these bricks contribute to the enhanced energy efficiency of furnaces, kilns, and other industrial applications. Moreover, insulating fire bricks are lightweight, effortlessly installable, and exhibit commendable strength and durability, rendering them a favored selection for refractory linings.

Send your message to us

Insulating Fire Brick - Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords