Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

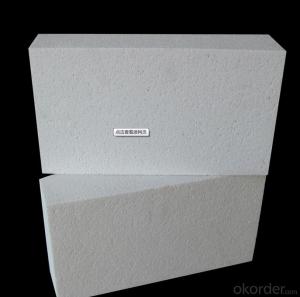

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-7

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-7

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:Refractory GJM Mullite Insulation Brick B-7

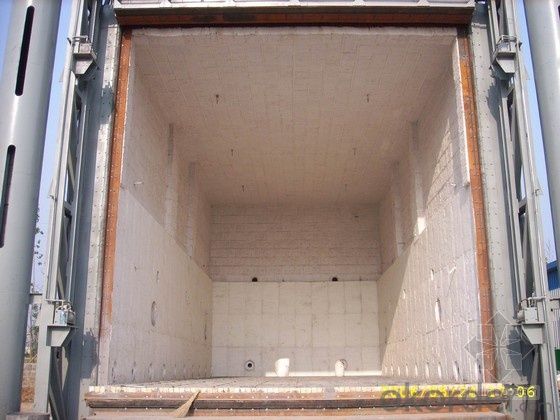

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-7

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-7

- Q: Are insulating fire bricks suitable for insulation in heat treatment furnaces?

- Yes, insulating fire bricks are suitable for insulation in heat treatment furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them ideal for use in heat treatment furnaces where maintaining consistent and controlled temperatures is crucial. These bricks help minimize heat loss, increase energy efficiency, and ensure uniform heating throughout the furnace, resulting in improved performance and cost savings.

- Q: Can insulating fire bricks be used for insulation in incinerators?

- Indeed, insulation in incinerators can be achieved by utilizing insulating fire bricks. Constructed from lightweight refractory materials, these bricks possess excellent insulating characteristics, rendering them highly suitable for applications demanding heat containment and energy efficiency, such as incinerators. Due to their low thermal conductivity, these bricks effectively trap and retain heat within the incinerator, thereby preventing heat leakage and enhancing the overall efficiency of the incineration procedure. Furthermore, insulating fire bricks exhibit remarkable resistance to high temperatures and can endure the harsh conditions commonly encountered in incinerators, establishing them as a dependable option for insulation purposes.

- Q: Can insulating fire bricks be used in solar power plants?

- Yes, insulating fire bricks can be used in solar power plants. They are commonly used in the construction of high-temperature equipment such as solar receivers, combustion chambers, and thermal energy storage systems. Insulating fire bricks help to minimize heat loss and maintain high operating temperatures, making them suitable for various applications in solar power plants.

- Q: Can insulating fire bricks be used in heat treatment furnaces?

- Yes, insulating fire bricks can be used in heat treatment furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in heat treatment furnaces where high temperatures are required. These bricks help to retain heat, minimize energy loss, and ensure efficient heat distribution throughout the furnace, resulting in improved heat treatment processes.

- Q: Are there any construction waste materials for composite thermal insulation bricks?

- Material production of ordinary light insulating brick clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating refractory brick, diatomite insulating refractory brick.

- Q: Do insulating fire bricks have a high resistance to spalling?

- Yes, insulating fire bricks have a high resistance to spalling. Spalling refers to the breaking off or flaking of the surface of a material, and in the case of fire bricks, it typically occurs due to high temperatures and thermal shock. Insulating fire bricks are specifically designed to withstand these extreme temperatures and thermal cycling, making them highly resistant to spalling. These bricks are made from high-quality refractory materials, such as alumina or silica, which have excellent thermal shock resistance. Additionally, they are manufactured with a low thermal conductivity, which helps to minimize heat transfer and reduce the risk of spalling. Overall, insulating fire bricks are an ideal choice for applications where high resistance to spalling is required, such as in furnaces, kilns, and other high-temperature environments.

- Q: Energy saving bricks or bricks?

- Energy saving brick may be cement slag, or cement, water residue, cement, coal ash, etc. overview

- Q: Are insulating fire bricks resistant to cracking?

- Insulating fire bricks possess a deliberate design aimed at achieving exceptional crack resistance. Crafted from lightweight ceramic substances with low thermal conductivity and remarkable thermal shock resistance, these bricks can endure swift temperature fluctuations without fracturing. Moreover, the bricks undergo a firing process that fortifies their structure and reduces the likelihood of cracking. Nevertheless, it is crucial to acknowledge that insulating fire bricks may still incur cracks under extreme thermal shock or physical impact. Hence, it is imperative to handle and install them properly to safeguard their durability and efficacy.

- Q: How do insulating fire bricks contribute to reducing heat loss?

- Insulating fire bricks contribute to reducing heat loss by providing a high level of thermal insulation. These bricks are specifically designed to have low thermal conductivity, which means they are able to trap and retain heat within a given space. This insulation property helps to prevent the transfer of heat from one side of the brick to the other, effectively reducing heat loss. By using insulating fire bricks, heat can be conserved and efficiently utilized, resulting in energy savings and improved overall thermal efficiency.

- Q: Are insulating fire bricks suitable for commercial or industrial applications?

- Insulating fire bricks are an ideal choice for commercial and industrial use. These bricks are specifically designed to withstand high temperatures and provide exceptional thermal insulation. They are commonly used in industries such as steel, cement, glass, and ceramics. In commercial settings, insulating fire bricks are frequently employed in kilns, furnaces, and ovens to ensure heat retention and energy efficiency. They help minimize heat loss, resulting in lower fuel consumption and cost savings for businesses. Additionally, their lightweight nature facilitates easy handling and installation, which is advantageous in time-sensitive commercial environments. In industrial applications, insulating fire bricks play a critical role in maintaining desired temperatures in industrial furnaces, reactors, and boilers. These bricks can endure extremely high temperatures, making them suitable for harsh industrial conditions. They also exhibit excellent resistance to thermal shock, preventing cracking or breaking when exposed to rapid temperature changes. Moreover, insulating fire bricks provide effective insulation against heat transfer, enhancing the overall efficiency of industrial processes. By reducing heat loss, they contribute to energy conservation and lower operating costs. Additionally, their durability and ability to withstand the demands of industrial operations make them a reliable choice for long-term use. In conclusion, insulating fire bricks are highly suitable for both commercial and industrial applications. Their exceptional thermal insulation properties, resistance to high temperatures, and durability make them the preferred choice in industries where heat retention, energy efficiency, and cost-effectiveness are of utmost importance.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords