Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

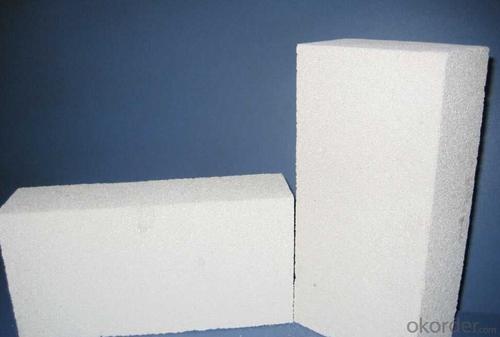

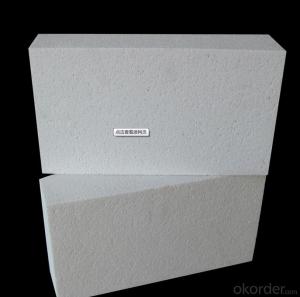

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:

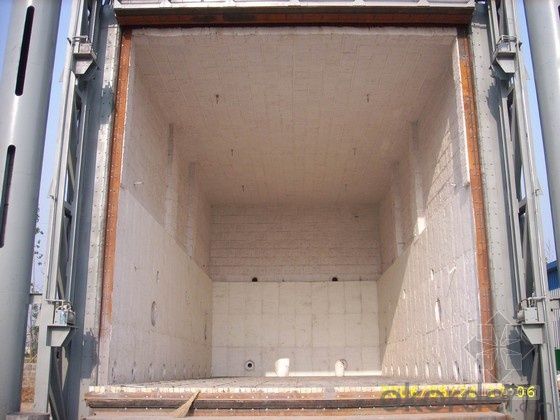

Refractory GJM Mullite Insulation Brick B-4

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Refractory GJM Mullite Insulation Brick B-4

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-4

- Q: Are insulating fire bricks resistant to nitric acid?

- Insulating fire bricks usually lack resistance against nitric acid, a highly corrosive substance that can dissolve various materials, including specific types of fire bricks. Although insulating fire bricks are intended for enduring high temperatures and providing thermal insulation, they may not possess the required chemical resilience to withstand the corroding impact of nitric acid. When anticipating exposure to nitric acid, it is recommended to employ materials specifically engineered for acid resistance in such situations.

- Q: What are the safety precautions when working with insulating fire bricks?

- When working with insulating fire bricks, it is important to follow several safety precautions to ensure the well-being of yourself and others. Here are some key safety measures to consider: 1. Personal protective equipment (PPE): Wear appropriate PPE, including heat-resistant gloves, long-sleeved clothing, safety goggles, and a respiratory mask. These will protect you from potential burns, cuts, and inhalation of harmful dust or fumes. 2. Proper ventilation: Work in a well-ventilated area or use local exhaust ventilation to minimize exposure to dust and fumes that may be released during handling or cutting of the bricks. 3. Fire prevention: Keep a fire extinguisher nearby and ensure the workspace is clear of flammable materials. Insulating fire bricks are highly refractory and can withstand high temperatures, but it is still important to prevent accidental fires. 4. Manual handling: Insulating fire bricks can be heavy, so use proper lifting techniques and avoid overexertion to prevent strains or injuries. If necessary, use mechanical aids such as trolleys or lifting equipment to move the bricks. 5. Cutting and grinding: When cutting or grinding the bricks, use appropriate tools and ensure they are in good working condition. This will minimize the risk of accidents or injuries. Be cautious of sharp edges and wear protective gloves to avoid cuts. 6. Temperature control: Insulating fire bricks are designed to withstand high temperatures, but avoid direct contact with hot surfaces. Use appropriate tools or equipment to handle the bricks when they are at an elevated temperature. 7. Storage and handling: Store the bricks in a cool, dry place away from direct sunlight or extreme temperatures. Avoid stacking them too high to prevent the risk of collapse or toppling. 8. Training and knowledge: Ensure you have received proper training and are familiar with the characteristics and properties of insulating fire bricks. Understand their limitations and follow the manufacturer's guidelines for safe handling and usage. By adhering to these safety precautions, you can significantly reduce the risk of accidents, injuries, and health hazards when working with insulating fire bricks. Remember, safety should always be a top priority in any workplace.

- Q: Can insulating fire bricks be used in the construction of glassware production furnaces?

- Yes, insulating fire bricks can be used in the construction of glassware production furnaces. These bricks have excellent thermal insulation properties and can withstand high temperatures, making them ideal for creating a well-insulated and efficient furnace for glass production.

- Q: Can insulating fire bricks be used in chimneys?

- Yes, insulating fire bricks can be used in chimneys. Insulating fire bricks are designed to withstand high temperatures, making them an ideal choice for lining chimneys. They have excellent thermal insulation properties, which help to prevent heat loss and increase the efficiency of the chimney. Additionally, insulating fire bricks are lightweight and easy to install, making them a convenient option for chimney lining. However, it is important to note that insulating fire bricks are not suitable for all types of chimneys. It is recommended to consult a professional or chimney specialist to determine the appropriate materials for your specific chimney needs.

- Q: Are insulating fire bricks fireproof?

- Indeed, insulating fire bricks possess fireproof properties. Their design allows them to endure elevated temperatures while offering insulation to impede heat transfer. Composed of refractory materials with a high melting point, insulating fire bricks can withstand intense heat without disintegrating or liquefying. These bricks are frequently employed in scenarios involving high temperatures, such as kilns, furnaces, fireplaces, and ovens. As a means of fireproofing, insulating fire bricks are highly recommended due to their exceptional thermal insulation capabilities and their ability to effectively safeguard against the propagation of fire.

- Q: Can insulating fire bricks be used for insulation in furnaces?

- Yes, insulating fire bricks can be used for insulation in furnaces. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in furnaces to reduce heat loss and increase energy efficiency.

- Q: Can insulating fire bricks be used for insulation in oil refineries?

- Yes, insulating fire bricks can be used for insulation in oil refineries. These bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for insulation applications in oil refineries where heat is generated. They can help reduce heat loss and increase energy efficiency in the refining process.

- Q: What are the disadvantages of using insulating fire bricks?

- There are several disadvantages of using insulating fire bricks that potential users should be aware of. Firstly, insulating fire bricks have a relatively low compressive strength compared to other types of bricks. This means that they may not be suitable for applications that require high structural integrity or load-bearing capacity. If the bricks are subjected to excessive pressure or heavy loads, they may crack or break, compromising the overall stability of the structure. Secondly, insulating fire bricks are more susceptible to erosion and wear compared to other types of bricks. They have a lower resistance to abrasion and chemical attack, which means they may deteriorate more quickly when exposed to harsh environments or aggressive substances. This can result in the need for more frequent maintenance or replacement of the bricks, leading to increased costs and efforts. Another disadvantage of insulating fire bricks is their relatively high thermal conductivity. While they are designed to provide insulation and reduce heat transfer, they still allow some heat to pass through. This can be a drawback in applications where maximum thermal insulation is required, as it may result in heat loss and decreased energy efficiency. Furthermore, insulating fire bricks are typically more expensive than regular bricks or other insulation materials. Their specialized composition and manufacturing process contribute to higher production costs, which are then passed on to the consumer. This can make them less cost-effective for certain applications, especially when cheaper alternatives with similar insulation properties are available. Lastly, insulating fire bricks are generally not suitable for use in direct contact with high-temperature flames or extreme thermal conditions. While they can withstand high temperatures, there is a limit to their heat resistance. Exceeding this limit can cause the bricks to crack or even disintegrate, rendering them ineffective as insulation and potentially compromising the safety of the surrounding environment. In conclusion, while insulating fire bricks offer several advantages in terms of thermal insulation and lightweight properties, they also have some disadvantages that should be considered. These include low compressive strength, susceptibility to erosion and wear, relatively high thermal conductivity, higher cost compared to other materials, and limited tolerance to extreme thermal conditions.

- Q: Do insulating fire bricks have a high compressive strength?

- Yes, insulating fire bricks typically have a high compressive strength. These bricks are made from special refractory materials that are designed to withstand high temperatures and mechanical stress. As a result, they have excellent compressive strength, allowing them to bear heavy loads without cracking or breaking. The high compressive strength of insulating fire bricks makes them ideal for applications where structural integrity is crucial, such as in furnaces, kilns, and other high-temperature industrial equipment.

- Q: Can insulating fire bricks be used in a refractory lining?

- Yes, insulating fire bricks can be used in a refractory lining. Insulating fire bricks are made from lightweight materials and have high insulating properties, which make them suitable for use in refractory linings to reduce heat loss and improve energy efficiency.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords