Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-6

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-6

Description:

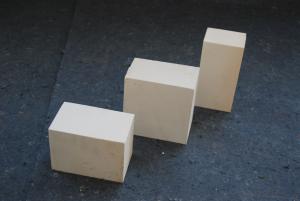

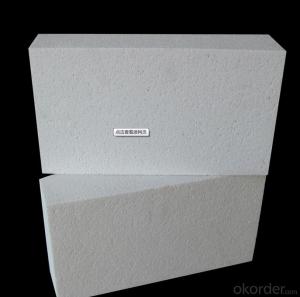

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:Refractory GJM Mullite Insulation Brick B-6

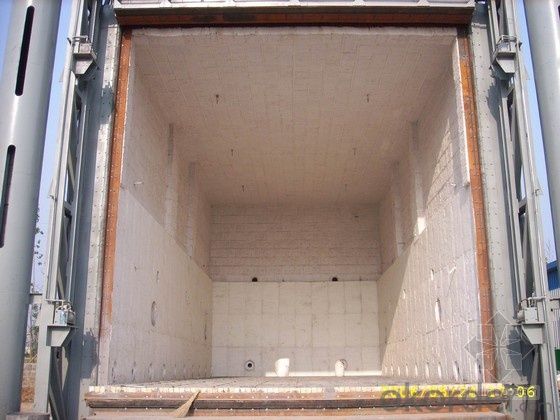

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-6

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very muchRefractory GJM Mullite Insulation Brick B-6

- Q: Are insulating fire bricks resistant to insect infestation?

- Insulating fire bricks are not specifically designed to be resistant to insect infestation. These bricks are primarily used for their thermal insulation properties in high-temperature applications such as kilns, furnaces, and fireplaces. While they are not typically prone to insect damage, they are not completely immune to it either. Insects may still be able to penetrate the bricks if they find small cracks or openings in the material. However, insulating fire bricks are generally dense and compact, making it difficult for insects to burrow or nest within them. It is always recommended to take preventive measures to control and eliminate potential insect infestations in any construction material, including insulating fire bricks, to ensure their longevity and functionality.

- Q: Do insulating fire bricks have low thermal conductivity?

- Yes, insulating fire bricks have low thermal conductivity.

- Q: What industries commonly use insulating fire bricks?

- Insulating fire bricks find widespread use in diverse industries that require high-temperature insulation. Some of the sectors that commonly utilize these bricks are: 1. Steel industry: Furnaces, kilns, and other equipment in steel manufacturing plants are lined with insulating fire bricks to enhance insulation, minimize heat loss, and optimize energy efficiency. 2. Glass industry: Insulating fire bricks are employed in furnaces and ovens where glass is melted and molded. They maintain high temperatures, minimize heat loss, and ensure consistent and efficient production. 3. Ceramic industry: Ceramic kilns and pottery ovens rely on insulating fire bricks for thermal insulation, which helps maintain the desired temperature for clay and ceramic products. These bricks conserve energy and optimize firing processes. 4. Cement industry: Cement kilns require efficient high-temperature insulation, achieved through the use of insulating fire bricks. They line the kilns, reducing heat loss and improving thermal efficiency. 5. Foundry industry: Foundries use insulating fire bricks to line melting furnaces and ovens for metal casting. These bricks retain heat, ensuring consistent and efficient metal melting. 6. Power generation industry: Boilers, furnaces, and incinerators in power plants benefit from the thermal insulation provided by insulating fire bricks. They prevent heat loss, improving overall power generation efficiency. 7. Petrochemical industry: Refineries and chemical processing plants rely on insulating fire bricks to line reactors, furnaces, and ovens. These bricks offer insulation against high temperatures and harsh chemical environments. 8. Pharmaceutical industry: Insulating fire bricks are used in pharmaceutical manufacturing facilities to line ovens and dryers. They enable precise temperature control and enhance energy efficiency. In conclusion, insulating fire bricks have wide-ranging applications in industries that emphasize the importance of high-temperature insulation for efficient and cost-effective operations.

- Q: Can insulating fire bricks be used to line industrial boilers?

- Yes, insulating fire bricks can be used to line industrial boilers. Insulating fire bricks are specially designed to have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in the boiler system. These bricks are made from lightweight materials such as clay and alumina, which have excellent insulation properties. By lining the interior of the boiler with insulating fire bricks, the heat generated by the combustion process can be contained within the boiler, resulting in higher heating efficiency and reduced fuel consumption. Additionally, insulating fire bricks can withstand high temperatures and thermal shocks, making them suitable for the harsh operating conditions often encountered in industrial boilers. Overall, using insulating fire bricks as a lining material in industrial boilers can contribute to improved energy efficiency, reduced operating costs, and increased durability of the boiler system.

- Q: Is it possible to paint or coat insulating fire bricks?

- Yes, it is possible to paint or coat insulating fire bricks. However, it is important to use a paint or coating that can withstand high temperatures, as insulating fire bricks are designed to be used in extremely hot environments. Regular paint or coatings may not be suitable as they can burn or deteriorate when exposed to high temperatures. It is recommended to use specialized high temperature paint or coatings that are specifically formulated to withstand the heat of insulating fire bricks. These paints or coatings typically have a high temperature resistance of several hundred degrees Celsius or more. Additionally, it is important to properly clean and prepare the surface of the bricks before applying any paint or coating to ensure good adhesion and durability.

- Q: Can insulating fire bricks be used in the construction of hot air generators?

- Indeed, the utilization of insulating fire bricks is applicable in the fabrication of hot air generators. Specifically engineered to endure extreme temperatures and deliver exceptional thermal insulation, insulating fire bricks are well-suited for incorporation into hot air generators. These generators necessitate insulation to uphold elevated temperatures and avert heat dissipation. By diminishing heat transfer to the surroundings, insulating fire bricks effectively enhance the efficiency and functionality of hot air generators. Furthermore, their lightweight nature, effortless installation, and long-lasting durability contribute to their widespread adoption in diverse industrial sectors, including the construction of hot air generators.

- Q: Can insulating fire bricks be used in DIY projects?

- Yes, insulating fire bricks can certainly be used in DIY projects. These bricks are lightweight and have excellent thermal insulation properties, making them suitable for various applications. They are commonly used in projects such as constructing wood-fired ovens, fire pits, kilns, and even for building the walls of a forge. Insulating fire bricks can withstand high temperatures and are resistant to thermal shock, making them a reliable choice for DIY enthusiasts who want to create heat-resistant structures. They are also easy to cut and shape, allowing for customization according to specific project needs.

- Q: Can insulating fire bricks be used in electric furnaces?

- Indeed, electric furnaces can utilize insulating fire bricks. These bricks are intentionally engineered to possess a minimal thermal conductivity, rendering them highly suitable for situations necessitating heat containment or insulation. Electric furnaces necessitate insulation to thwart heat dissipation and enhance energy efficacy. Insulating fire bricks can endure extreme temperatures and possess exceptional insulation attributes, rendering them a fitting choice for electric furnace applications. Moreover, their lightweight nature and effortless installation make them a favored option for electric furnace insulation.

- Q: Can insulating fire bricks be used in the construction of glass bottle production furnaces?

- Yes, insulating fire bricks can be used in the construction of glass bottle production furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are often used in applications that require heat retention and energy efficiency, such as furnaces. By using insulating fire bricks in the construction of glass bottle production furnaces, the heat generated during the glass-making process can be effectively contained within the furnace, reducing heat loss and improving energy efficiency. This can result in cost savings and improved production performance. Additionally, insulating fire bricks can help protect the structural integrity of the furnace by minimizing thermal stress and preventing heat transfer to the surrounding environment. Overall, the use of insulating fire bricks in glass bottle production furnaces can contribute to more efficient and durable furnace operation.

- Q: Do insulating fire bricks have a high resistance to creep?

- Yes, insulating fire bricks generally have a high resistance to creep. The low thermal conductivity and high refractoriness of these bricks allow them to withstand high temperatures without significant deformation or creep.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords