Insulating Fire Brick - Mullite Refractory Jm 23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKORDER Series Insulating Bricks

OKORDER series insulating bricks are a kind of highly efficient, energy saving, low-carbon, environmental protection advanced products which are manufactured according to ASTM standard. OKORDER series products are the best lining and insulation materials in all types of industrial furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass. They can be applied as heat insulation or no-melt erosion parts of the working layer. The products have been widely used in the following furnaces and achieved satisfactory results.

Application of Insulating Bricks

Metallurgy industry: Blast furnace, Hot blast stove, Reheating furnace, etc.

Petrochemical industry: Ethylene cracking furnace, Hydrogen production furnace, Primary reformer furnace, Reheating furnace, etc.

Ceramics Industry: Roller kiln, Pusher kiln, etc.

Glass industry: Glass furnace regenerator, etc.

Carbon Industry: Carbon roaster, etc.

Aluminum electrolytic industry: aluminum reduction cells,etc.

Other industries: Tunnel kiln, Shuttle kiln, etc.

Advantages of Insulating Bricks

Low Thermal Conductivity: More porosity brings excellent insulation effect, energy saving.

High Crushing Strength: High crushing strength under thermal state, volume stability.

Low Heat Storage: Little thermal storage when absorb more heat, energy saving effect is obvious.

High Purity: Low content of iron, alkaline and metal impurities.

Accurate Dimension: Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

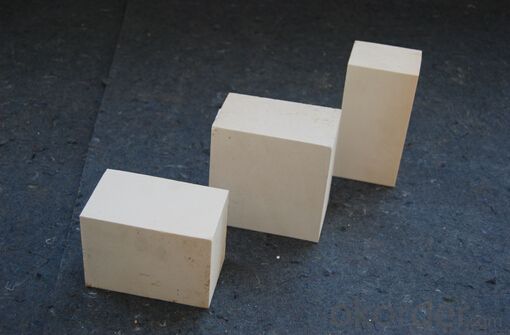

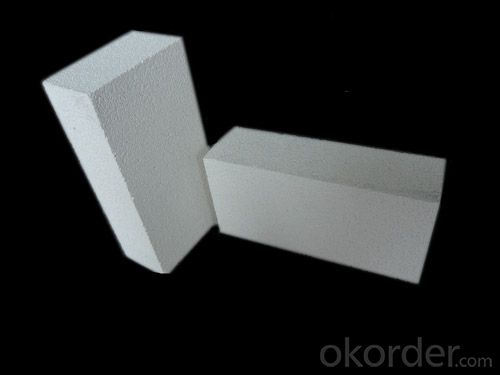

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Can insulating fire bricks be used in the construction of boilers for power plants?

- Insulating fire bricks have the capability to be utilized in the construction of boilers for power plants. These bricks are specially designed to possess a low thermal conductivity, enabling them to retain heat and prevent the loss of energy. This particular characteristic makes them well-suited for high-temperature applications like power plant boilers, where efficient heat transfer is vital for the production of steam and the generation of electricity. Furthermore, insulating fire bricks are lightweight and exhibit good resistance to thermal shocks, making them appropriate for the demanding conditions typically encountered in power plants. On the whole, incorporating insulating fire bricks into the construction of boilers can enhance energy efficiency and diminish heat loss, resulting in improved operational performance and cost savings for power plants.

- Q: Are insulating fire bricks resistant to vibration or seismic activity?

- Yes, insulating fire bricks are typically resistant to vibration or seismic activity. They are designed to withstand high temperatures and provide insulation, which also makes them relatively stable and resistant to external forces such as vibrations or seismic activity.

- Q: Can insulating fire bricks be cut or shaped using common tools?

- Yes, insulating fire bricks can be cut or shaped using common tools. These bricks are generally made from lightweight refractory materials such as clay and minerals, which make them easier to cut and shape compared to traditional fire bricks. Common tools like a handsaw, angle grinder, or even a chisel and hammer can be used to cut and shape the bricks according to the desired size and design. However, it is important to wear protective gear such as gloves, goggles, and a dust mask while working with insulating fire bricks to avoid any potential health hazards.

- Q: Can insulating fire bricks be used for soundproofing?

- Insulating fire bricks are primarily designed for high-temperature applications, such as lining kilns and furnaces, due to their ability to withstand extreme heat. While they do offer some level of sound insulation due to their dense composition, they are not specifically designed or recommended for soundproofing purposes. Insulating fire bricks are more effective at blocking heat transfer than sound transmission. For soundproofing purposes, other materials specifically engineered for acoustic insulation, such as mineral wool, fiberglass, or foam panels, are typically used. These materials are designed to absorb and dampen sound waves, providing better soundproofing results. Therefore, if your goal is to soundproof a space, it is recommended to use materials specifically designed for that purpose rather than relying on insulating fire bricks.

- Q: Do insulating fire bricks require a refractory mortar for installation?

- Yes, insulating fire bricks typically require a refractory mortar for proper installation. Refractory mortar helps to secure the bricks in place, fill any gaps or voids, and provide additional insulation and strength to the overall structure.

- Q: Can insulating fire bricks be used in textile industry kilns?

- Yes, insulating fire bricks can be used in textile industry kilns. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in kilns where textiles are processed or treated. Insulating fire bricks help maintain consistent temperatures, enhance energy efficiency, and protect the kiln from heat damage.

- Q: How do insulating fire bricks help improve the efficiency of heat recovery systems?

- Insulating fire bricks play a crucial role in improving the efficiency of heat recovery systems in several ways. Firstly, these bricks are made from high-quality insulating materials such as ceramic fiber, which have excellent thermal properties. This means that they have a low thermal conductivity, preventing heat from escaping or being wasted. By using insulating fire bricks as lining materials in heat recovery systems, the heat exchange process becomes more efficient as less heat is lost to the surroundings. Secondly, insulating fire bricks help to reduce heat transfer through conduction. They act as a barrier between the hot and cold sides of the system, minimizing heat loss through direct contact. This insulation effect allows the heat recovery system to maintain a higher temperature on the hot side, maximizing the temperature difference and thus enhancing the heat transfer rate. Additionally, insulating fire bricks are lightweight and have low heat storage capabilities. This means that they require less energy to heat up and cool down, resulting in faster response times of the heat recovery system. This quick response enables the system to adapt rapidly to changes in heat generation or demand, improving its overall efficiency. Moreover, the use of insulating fire bricks as refractory materials in heat recovery systems helps to reduce energy consumption. Since these bricks can withstand high temperatures without cracking or deforming, they contribute to the longevity of the system, reducing the need for frequent repairs or replacements. This leads to lower maintenance costs and less downtime, ultimately improving the overall energy efficiency of the heat recovery system. In summary, insulating fire bricks enhance the efficiency of heat recovery systems by providing excellent thermal insulation, reducing heat loss through conduction, enabling quick response times, and minimizing energy consumption. Their use as lining materials significantly improves the heat transfer process, resulting in more effective heat recovery and utilization.

- Q: Can insulating fire bricks be used in the construction of lime production ovens?

- Yes, insulating fire bricks can be used in the construction of lime production ovens. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for the intense heat and thermal requirements of lime production ovens. They help maintain consistent temperature levels, reduce heat loss, and improve energy efficiency, making them a reliable choice for such applications.

- Q: Are insulating fire bricks resistant to weathering or aging?

- Yes, insulating fire bricks are generally resistant to weathering and aging. These bricks are designed to withstand high temperatures and harsh conditions, making them durable and long-lasting. They are often used in applications where exposure to extreme weather, such as rain, snow, and sunlight, is common. However, it is important to note that the specific composition and quality of the bricks can vary, so it is advisable to consult the manufacturer or supplier for detailed information regarding their weathering and aging resistance properties.

- Q: Can insulating fire bricks be used in lime plants?

- Yes, insulating fire bricks can be used in lime plants. They are commonly used in high-temperature applications, such as lime kilns, to provide thermal insulation and reduce heat loss. Insulating fire bricks help maintain consistent and efficient heat distribution, which is essential for the lime production process.

Send your message to us

Insulating Fire Brick - Mullite Refractory Jm 23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords