Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

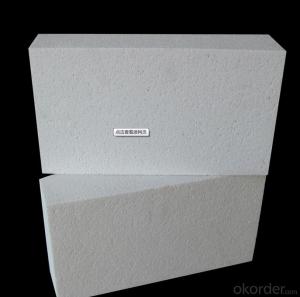

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-3

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-3

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:

Refractory GJM Mullite Insulation Brick B-3

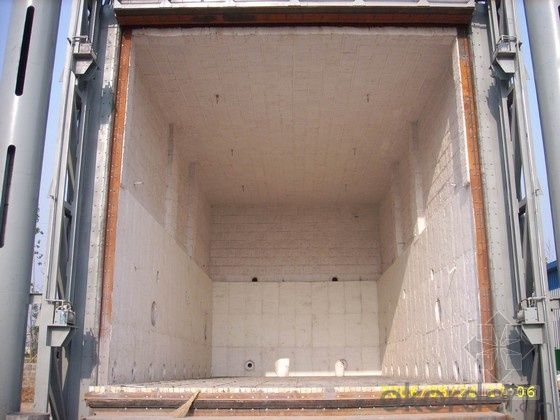

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Refractory GJM Mullite Insulation Brick B-3

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-3

- Q: Do insulating fire bricks have a low density?

- Yes, insulating fire bricks typically have a low density compared to other types of bricks.

- Q: Do insulating fire bricks require maintenance?

- Maintenance is required for insulating fire bricks. Despite their reputation for durability and ability to withstand high temperatures, it is important to regularly maintain them to ensure they perform at their best and last a long time. One crucial aspect of maintenance is periodic cleaning. Over time, insulating fire bricks can collect dust, soot, and other debris, which can impact their insulation properties. It is therefore advisable to clean the bricks regularly to eliminate any build-up. This can be achieved by using a soft brush or a mild cleaning solution. Another vital aspect of maintenance involves checking for any cracks or damages. It is essential to inspect the bricks for signs of wear and tear to identify and address any issues before they worsen. Cracks or damages can compromise the insulation and stability of the bricks, so they should be repaired or replaced as necessary. Additionally, it is important to monitor the condition of the mortar or refractory cement used to hold the insulating fire bricks together. Over time, the mortar can deteriorate due to exposure to heat and other elements. Regularly inspecting and repairing any damaged mortar helps to maintain the structural integrity of the fire bricks. Furthermore, it is crucial to adhere to the manufacturer's instructions and recommendations for the specific type of insulating fire bricks being used. This may involve following guidelines for installation, temperature limits, and any other specific care instructions. In conclusion, while insulating fire bricks are sturdy, regular maintenance is required to ensure they perform optimally and have a long lifespan. Proper cleaning, inspecting for damage, and following the manufacturer's guidelines are essential components of maintaining insulating fire bricks.

- Q: Can insulating fire bricks be used for insulation in sewage treatment plants?

- Yes, insulating fire bricks can be used for insulation in sewage treatment plants. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them suitable for use in environments where heat and moisture are present, such as sewage treatment plants. These bricks have low thermal conductivity, which helps to reduce heat loss and increase energy efficiency in the treatment process. Additionally, their resistance to chemicals and moisture makes them ideal for withstanding the corrosive environment found in sewage treatment plants. Therefore, insulating fire bricks can effectively provide insulation in sewage treatment plants, helping to maintain optimum operating temperatures and improve overall efficiency.

- Q: Can insulating fire bricks be used in the construction of ladles?

- Yes, insulating fire bricks can be used in the construction of ladles. These bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are commonly used in industrial applications such as ladle lining to maintain heat and prevent heat loss, ensuring efficient and safe operations in metal casting and foundry processes.

- Q: Is it possible to paint or coat insulating fire bricks?

- Yes, it is possible to paint or coat insulating fire bricks. However, it is important to use a paint or coating that can withstand high temperatures, as insulating fire bricks are designed to be used in extremely hot environments. Regular paint or coatings may not be suitable as they can burn or deteriorate when exposed to high temperatures. It is recommended to use specialized high temperature paint or coatings that are specifically formulated to withstand the heat of insulating fire bricks. These paints or coatings typically have a high temperature resistance of several hundred degrees Celsius or more. Additionally, it is important to properly clean and prepare the surface of the bricks before applying any paint or coating to ensure good adhesion and durability.

- Q: Are insulating fire bricks resistant to chemical attack?

- Yes, insulating fire bricks are generally resistant to chemical attack. These bricks are made from high-purity refractory materials, such as alumina or silica, which have excellent chemical stability. They are designed to withstand high temperatures and are thus highly resistant to the corrosive effects of chemicals. However, it is important to note that the degree of chemical resistance can vary depending on the specific composition of the insulating fire brick and the type of chemical being used. In some cases, certain aggressive chemicals may still cause some degree of degradation or erosion over time. Therefore, it is always recommended to consult the manufacturer or supplier for specific information regarding the chemical resistance of insulating fire bricks in relation to the intended application.

- Q: How do insulating fire bricks affect the overall thermal stability of a structure?

- Insulating fire bricks play a crucial role in enhancing the overall thermal stability of a structure. These bricks are designed to have low thermal conductivity, which means they are effective in minimizing heat transfer between different parts of a structure. By using insulating fire bricks, the amount of heat that can escape or enter a structure is significantly reduced, resulting in improved thermal stability. In cold weather, these bricks prevent heat from escaping, keeping the interior of the structure warm and reducing the need for excessive heating. Conversely, in hot weather, they prevent the entry of external heat, helping to keep the interior cool and reducing the need for excessive cooling. The low thermal conductivity of insulating fire bricks also helps in maintaining a consistent temperature within the structure. This is particularly important in areas where there are significant temperature fluctuations, as it helps to regulate the internal climate, making the structure more comfortable for its occupants. Furthermore, insulating fire bricks are known for their high resistance to thermal shock. This means that they can withstand rapid changes in temperature without cracking or breaking. By providing a stable and durable barrier against extreme temperatures, these bricks contribute to the overall thermal stability of a structure, ensuring its longevity and reliability. Overall, insulating fire bricks have a positive impact on the thermal stability of a structure by reducing heat transfer, maintaining consistent temperatures, and withstanding thermal shock. Their use can significantly enhance the comfort, energy efficiency, and durability of a building.

- Q: Are insulating fire bricks resistant to ultraviolet (UV) radiation?

- No, insulating fire bricks are not resistant to ultraviolet (UV) radiation.

- Q: Are insulating fire bricks resistant to ammonia gas?

- Insulating fire bricks, in general, lack resistance against ammonia gas. Although these bricks are engineered to endure elevated temperatures and offer thermal insulation, they are commonly constructed from lightweight refractory materials, like clay or silica, which are not particularly resilient to corrosive substances such as ammonia gas. Over time, ammonia gas can react with these materials and result in deterioration or harm to the bricks. Consequently, if you require fire bricks for an environment containing ammonia gas, it is advisable to opt for specially designed acid-resistant or chemical-resistant bricks that can endure the corrosive impact of ammonia gas.

- Q: Do insulating fire bricks require a specific curing or drying process before use?

- Insulating fire bricks typically necessitate a distinct curing or drying procedure prior to utilization. This action eradicates any moisture or volatile organic compounds (VOCs) that could be within the bricks and guarantees they attain their utmost insulating capabilities. The curing or drying procedure for insulating fire bricks generally entails a gradual increase in temperature, allowing the release of any moisture or VOCs without causing cracks or damage to the bricks. The rate of temperature escalation and the overall duration of the curing process may differ based on the bricks' type and thickness. Adhering to the manufacturer's instructions and recommendations for the specific type of insulating fire bricks employed is crucial. This ensures that the curing or drying process is executed accurately, preparing the bricks for use in high-temperature applications like kilns, furnaces, or fireplaces. Failing to appropriately cure or dry the bricks may lead to diminished insulating properties, as well as potential cracks or failure when subjected to elevated temperatures.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords