Rebar Near Me - Construction Deformed Steel Rebar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Construction Deformed Steel Rebar:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Packing | Export standard packing: wrapped by wire rod in bundles | ||

Each bundle weight | 2-3MT, or as required | ||

Inspection | Accept the third party inspection | ||

Type | Hot rolled steel rebar | ||

Brand name | DRAGON | ||

Chemical Composition: (Please kindly find our chemistry of our material based on BS4449 as below for your information)

BS4449 G460B | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.18 | 0.35 | 0.14 | 0.025 | 0.25 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

625 | ≥460 | 18 | |||

BS4449 500B | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.24 | 0.45 | 0.16 | 0.05 | 0.31 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

650 | ≥500 | 19 | |||

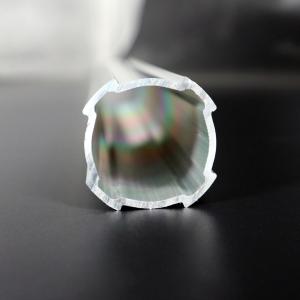

Deformed Steel Rebar in factory

Usage and Applications of Construction Deformed Steel Rebar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Construction Deformed Steel Rebar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Delivery Detail: within 45 days after received advanced payment or LC.

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q:Can steel rebars be used in the construction of hotels and resorts?

- Yes, steel rebars can be used in the construction of hotels and resorts. Steel rebars are commonly used as reinforcement in concrete structures to provide strength and durability. In the construction of hotels and resorts, where large-scale and high-quality structures are required, steel rebars are often used to ensure the safety and stability of the buildings.

- Q:What are the common defects observed in steel rebars?

- Steel rebars can exhibit several common defects, including rust and corrosion, cracks and fractures, lack of bond, bent or deformed shapes, dimensional inaccuracies, and inclusions or impurities. When exposed to moisture and oxygen, rebars are susceptible to rust and corrosion, which weaken their structural integrity and compromise the overall strength of concrete structures. Various factors such as excessive bending, improper handling during transportation and installation, or overloading can lead to cracks and fractures in rebars, reducing their load-bearing capacity and affecting the performance of concrete structures. Adequate bond between rebars and the surrounding concrete is crucial for effective load transfer, but poor surface preparation, improper placement, or the presence of contaminants can result in a lack of bond and reduced structural strength. Improper bending techniques, excessive bending, or mishandling can result in rebars with incorrect shapes or deformities, compromising their structural integrity and load-bearing capacity. Steel rebars must conform to specific dimensional tolerances to ensure proper fit and alignment within concrete structures, but manufacturing errors or improper storage and handling can cause dimensional inaccuracies, leading to difficulties during installation and potentially impacting structural performance. Ideally, steel rebars should be free from any inclusions or impurities that can weaken the material, but inadequate quality control during the manufacturing process can result in the presence of foreign materials or impurities, reducing the strength and durability of rebars. To minimize these defects and ensure the long-term structural integrity of concrete structures, it is important to implement proper quality control measures and adhere to industry standards during the manufacturing, transportation, and installation of steel rebars.

- Q:What are the limitations of using steel rebars in construction?

- One limitation of using steel rebars in construction is their susceptibility to corrosion. When exposed to moisture and oxygen, steel rebars can rust over time, compromising the structural integrity of the concrete. Additionally, steel rebars are relatively heavy, which can increase the overall weight of the structure and potentially require additional support. Lastly, steel rebars can be expensive, especially in regions where the cost of steel is high, making alternative reinforcement materials more appealing from a cost perspective.

- Q:Can steel rebars be used in fire-resistant structures?

- Yes, steel rebars can be used in fire-resistant structures. Steel has a high melting point and retains its strength even at high temperatures. However, to enhance fire resistance, additional measures such as fireproof coatings or concrete encasement may be necessary.

- Q:Can steel rebars be used in the construction of residential communities?

- Yes, steel rebars can be used in the construction of residential communities. Steel rebars are commonly used in the construction industry for reinforcing concrete structures, including residential buildings. They provide strength and durability to the concrete, improving its load-bearing capacity and resistance to cracks and other forms of structural damage. Steel rebars are often used in residential construction to reinforce foundation footings, walls, columns, and beams. They help to ensure the structural integrity of the building, making it safer and longer-lasting. Additionally, steel rebars can be easily customized and shaped to fit specific design requirements, allowing for flexibility in construction. Overall, the use of steel rebars in residential communities is a common and widely accepted practice in the construction industry.

- Q:How are steel rebars protected against corrosion?

- Steel rebars are protected against corrosion through various methods such as applying a protective coating, using corrosion inhibitors, cathodic protection, and ensuring proper concrete cover to prevent exposure to moisture and aggressive chemicals.

- Q:What are the common grades of steel rebars?

- The common grades of steel rebars include Grade 40, Grade 60, and Grade 75.

- Q:How are steel rebars stored on construction sites?

- Steel rebars are typically stored on construction sites in an organized manner, usually in designated areas called rebar cages or racks. These storage facilities are designed to keep the rebars off the ground and prevent them from getting damaged or rusted. The rebars are often sorted by size and type, and are secured in bundles or tied together using wire or straps. Additionally, they are stored in a way that allows easy access and efficient retrieval when needed for construction purposes.

- Q:How do steel rebars prevent concrete structures from collapsing?

- Steel rebars prevent concrete structures from collapsing by providing reinforcement and strength to the concrete. The rebars act as a framework within the concrete, helping distribute loads and resist tension forces. This added strength prevents cracks from forming and spreading, ensuring the structural integrity of the concrete and preventing collapse.

- Q:How are steel rebars used in parking structures?

- Steel rebars are used in parking structures to reinforce the concrete and provide structural strength. They are typically embedded within the concrete to ensure that the structure can withstand heavy loads and resist any potential cracks or damages. The rebars help distribute the weight evenly, enhancing the overall stability and durability of the parking structure.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; East Asia; Middle east |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 40%-60% |

| No.of Employees in Trade Department | 21-60 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 850,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Rebar Near Me - Construction Deformed Steel Rebar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords