Deformed Steel Bar Astm A615 Grade 40 Grade 60 Rebar Steel Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

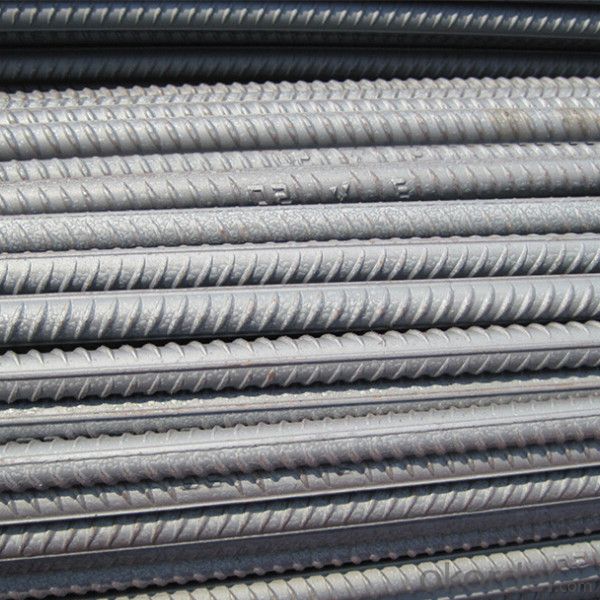

Deformed Steel Bar Astm A615 Grade 40 Grade 60 Rebar Steel Prices

Products Description:

Rebar is common known as steel reinforcing bar, usually applied to reinforced concrete and reinforced masonry structures. Formed from mild steel, it is given ribs for better frictional adhesion to the concrete. In other words rebar is an iron rod, a weldable plain reinforcing steel bar, that it can be also used for steel meshes.

1. Diameter: 5.5mm-10mm rounds reinforcing steel bar

10m- 40 rods reinforcing deformed steel bar

2. Length: 6m, 9m, 12m or customized

3. Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN. OEM technology - send detailed technical parameters for accurate quotation.

4. Produce Process: smelt iron - EAF smelt billet - ESR smelt billet - hot rolled or forged to get the steel round bar and plate

5. Heat Treatment: annealing, normalizing, tempering, quenching

6. Surface Treatment: Black

7. Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Theoretical weight and section area:

| Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

| 8 | 50.27 | 0.395 | 4.74 |

| 12 | 113.1 | 0.888 | 10.656 |

| 16 | 201.1 | 1.58 | 18.96 |

| 20 | 314.2 | 2.47 | 29.64 |

| 25 | 490.9 | 3.85 | 46.2 |

| 32 | 804.2 | 6.31 | 75.72 |

| 40 | 1257 | 9.87 | 118.44 |

| 50 | 1964 | 15.42 | 185.04 |

Technical Datas:

Grade | Technical data of the original chemical composition (%) | |||||

| C | Mn | Si | S | P | V | |

| ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

HRB400 | Physical capability | |||||

| Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | ||||

| ≥400 | ≥570 | ≥14 | ||||

Products Show:

Packages and Shipping:

| Packaging | A seaworthy pachaging or as per customer required |

| Shipping | 10- 30days after we receive 30% deposite |

FAQ:

1. Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Payment Terms?

30% TT as deposit and 70% before delivery. Or Irrevocable L/C at sight.

4. Trading Terms?

EXW, FOB, CIF, FFR, CNF

5. After-sale Service

We provide the services and support you need for every step of our cooperation. We're the business partner you can trust. For any problem, please kindly contact us at any your convenient time.

- Q: Are steel rebars suitable for use in extreme temperatures?

- Yes, steel rebars are suitable for use in extreme temperatures. Steel has excellent thermal properties and can withstand both high and low temperatures without significant loss in strength or structural integrity. This makes steel rebars a reliable choice for reinforcing concrete structures in extreme temperature conditions.

- Q: How do steel rebars affect the durability of a structure?

- Steel rebars greatly enhance the durability of a structure by providing reinforcement and strength to withstand external forces, such as tension and compression. They improve the structural integrity, increase resistance to cracking and bending, and ensure long-term stability, making the structure more resistant to corrosion and structural failure.

- Q: What is the diameter range of steel rebars?

- The diameter range of steel rebars typically varies from 6mm to 50mm.

- Q: Can steel rebars be used in non-load-bearing structures?

- Yes, steel rebars can be used in non-load-bearing structures. While rebars are primarily used for reinforcing concrete in load-bearing structures, they can also be employed in non-load-bearing structures such as decorative or architectural elements.

- Q: Can steel rebars be used in power plant construction?

- Power plant construction can indeed utilize steel rebars. These rebars, also referred to as reinforcing bars, are frequently employed in the construction sector to provide concrete structures with strength and support. In power plant construction, it is common practice to reinforce concrete foundations, walls, and structural components like columns and beams with steel rebars. The remarkable tensile strength and durability of these rebars make them highly suitable for enduring the heavy loads and extreme conditions typically encountered in power plant environments. Additionally, steel rebars can enhance the overall strength and stability of power plant infrastructure by being employed in the construction of reinforcing cages for underground pipelines and cooling towers.

- Q: Are steel rebars suitable for use in structures with high impact resistance requirements?

- High tensile strength and the ability to withstand heavy loads make steel rebars a common choice in construction. However, they may not be suitable for structures with high impact resistance requirements. Although steel rebars are strong, they do not possess the same level of impact resistance as materials like fiberglass or carbon fiber. For structures that are exposed to heavy impact loads, such as bridges, earthquake-resistant buildings, or structures at risk of collisions with heavy machinery or vehicles, alternative materials may be more appropriate. For instance, fiberglass rebars offer improved impact resistance due to their flexibility and capacity to absorb energy without breaking. Moreover, they have a higher strength-to-weight ratio compared to steel rebars. In contrast, carbon fiber rebars have exceptional impact resistance and are commonly utilized in aerospace and military applications. In conclusion, while steel rebars are reliable for many structural purposes, structures requiring high impact resistance may benefit from the use of alternative materials like fiberglass or carbon fiber rebars. It is crucial to carefully evaluate the specific needs and demands of the structure to ensure both its durability and safety.

- Q: What are the different types of steel rebars used in industrial constructions?

- There are several different types of steel rebars that are commonly used in industrial constructions. These rebars are essential for reinforcing concrete structures and providing strength and durability to the overall construction. Some of the main types of steel rebars used in industrial constructions include: 1. Mild Steel Rebars: Also known as black steel rebars, these are the most commonly used type of rebars in construction. They are made from carbon steel and have a smooth surface. Mild steel rebars provide adequate strength and are cost-effective, making them suitable for a wide range of industrial applications. 2. High-strength Deformed Steel Rebars (HSD): These rebars have ribs or deformations on their surface to provide better bonding with concrete. HSD rebars are made from carbon steel and undergo a process called thermomechanical treatment to increase their strength. These rebars are commonly used in heavy-duty industrial constructions where higher strength is required. 3. Epoxy-coated Rebars: These rebars are coated with an epoxy resin to protect them from corrosion. Epoxy-coated rebars are commonly used in areas where the concrete is exposed to moisture or chemicals, such as bridges and marine structures. The epoxy coating acts as a barrier, preventing corrosion and extending the lifespan of the structure. 4. Galvanized Rebars: Galvanized rebars are coated with a layer of zinc to provide corrosion resistance. The zinc coating acts as a sacrificial layer, protecting the steel rebars from rusting. These rebars are commonly used in areas where the concrete is exposed to harsh environmental conditions or in coastal regions where the risk of corrosion is high. 5. Stainless Steel Rebars: Stainless steel rebars are highly corrosion-resistant and are used in environments that require exceptional durability and resistance to corrosion. They are commonly used in industrial constructions that are exposed to aggressive chemicals, high humidity, or extreme temperatures. Each type of steel rebar has its own set of advantages and is suitable for different applications based on the specific requirements of the industrial construction project. It is important to carefully consider factors such as strength, corrosion resistance, and cost when selecting the appropriate type of steel rebar for a particular construction project.

- Q: Laiwu steel thread steel trademark color blue and red Qu Qu

- The current steel market shoddy (commonly known as hot rolled ribbed steel rebar) unqualified factors are mainly: 1, the actual size than the nominal size is small, the actual weight of dealers through purchase, the amount of metal delivery weight theory earn profits. 2, the intensity is low. 3, the chemical composition unqualified rate is high. The main reason is that the raw material of the small rolling mill is not qualified, and the steel billet is rolled by soil.

- Q: How are steel rebars transported and stored on construction sites?

- Trucks or trailers are typically used to transport steel rebars to construction sites. These vehicles are specifically designed to safely carry and unload the heavy and bulky rebars. When the rebars arrive at the site, they are usually offloaded using cranes or forklifts. To make storage and access more efficient, rebars are often kept in designated areas known as rebar yards. These yards are typically organized in a manner that allows for easy identification and retrieval of rebars when needed. The rebars are sorted and stacked according to their size, length, and type to avoid any confusion during construction. In the rebar yard, rebars are commonly stored horizontally on racks made of steel or wood. These racks are designed to provide proper support and prevent any damage to the rebars. It's important to note that rebars should be stored above ground level to protect them from moisture, rust, and contamination. They should also be kept away from damp areas and direct contact with soil. To maintain the quality of the rebars, it's crucial to protect them from rain, snow, and excessive sunlight. Therefore, construction sites often utilize protective covers like tarps or plastic sheets to shield the rebars and prevent any corrosion or deterioration. Additionally, construction workers must handle rebars with care to avoid bending or deformation. Special attention should be paid to prevent dropping or dragging of rebars, as it can compromise their structural integrity. Overall, careful planning and adherence to safety guidelines are necessary for the transportation and storage of steel rebars on construction sites. This ensures the rebars maintain their quality and effectiveness in reinforcing concrete structures.

- Q: What are the guidelines for repairing damaged steel rebars in a structure?

- When it comes to repairing damaged steel rebars in a structure, there are several guidelines that need to be followed to ensure the structural integrity of the building. Here are some key guidelines: 1. Inspection: Before starting the repair process, a thorough inspection of the damaged rebars should be conducted. This includes assessing the extent of the damage, identifying the cause of the damage, and determining whether repair is feasible or if replacement is required. 2. Cleaning: The damaged rebars need to be cleaned properly to remove any loose rust, scale, or other contaminants. This can be done using wire brushes, sandblasting, or other appropriate cleaning methods. 3. Removal of damaged material: Any corroded or severely damaged portions of the rebars should be removed. This may involve cutting out the damaged area and replacing it with a new rebar, or using techniques such as welding or epoxy bonding to repair the damaged section. 4. Surface preparation: The surface of the rebars should be prepared to ensure proper adhesion of the repair material. This may involve roughening the surface, applying a bonding agent, or using other surface preparation techniques depending on the specific repair method being employed. 5. Repair material selection: The choice of repair material will depend on factors such as the severity of the damage, the load-bearing capacity required, and the environment in which the rebars are located. Common repair materials include epoxy resins, cementitious mortars, or other specialized repair products. 6. Repair technique: The repair technique chosen should be appropriate for the specific damage and should comply with relevant industry standards and codes. Techniques such as welding, epoxy bonding, or mechanical splicing can be used to repair damaged rebars. 7. Quality control: Throughout the repair process, quality control measures should be implemented to ensure the effectiveness and durability of the repair. This may involve testing the repaired rebars for strength, monitoring the curing process, and conducting inspections to verify that the repairs have been carried out in accordance with the guidelines. 8. Documentation: It is essential to maintain thorough documentation of the repair process, including photographs, test results, and any relevant certifications or warranties. This documentation can be useful for future reference, maintenance, and to provide evidence of the repair work done. It is important to note that the guidelines for repairing damaged steel rebars may vary depending on the specific requirements of each project, local building codes, and the recommendations of structural engineers or repair specialists. Therefore, it is crucial to consult with experts in the field to ensure that the repair work is carried out safely and effectively.

Send your message to us

Deformed Steel Bar Astm A615 Grade 40 Grade 60 Rebar Steel Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords