Steel Rebar KS Standard SD400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

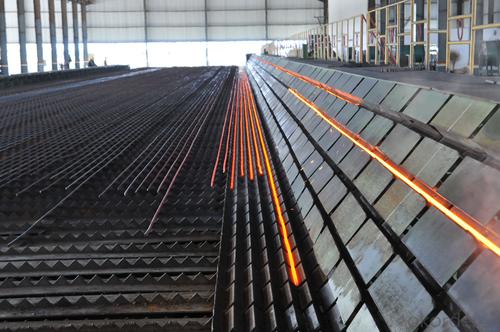

OKorder is offering Steel Rebar KS Standard SD400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Rebar KS Standard SD400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Rebar KS Standard SD400 are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SD400,SD500

Size: 6mm-32mm

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| DEFORMED BAR | |

| SIZE d(mm) | theoretical kg/m |

| 6 | 0.222 |

| 8 | 0.395 |

| 10 | 0.617 |

| 12 | 0.888 |

| 14 | 1.21 |

| 16 | 1.58 |

| 18 | 2 |

| 20 | 2.47 |

| 22 | 2.98 |

| 25 | 3.85 |

| 28 | 4.83 |

| 32 | 6.31 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q3: what is the difference between actual weight and theoretical weight?

A3: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Images:

- Q: What is the difference between the II and III grades of threaded steel?

- Compared with traditional II grade steel, the characteristics are as follows:1, high corrosion resistance, can be a large number of security reserves.2. In the chemical composition, because of the low carbon equivalent of the new third grade steel, the welding performance is good.3, high strength ratio, meet the seismic performance requirements. Particularly suitable for high-rise buildings and high seismic performance requirements of the project.4, cold bending performance is good, can be repeatedly bent, more in line with and meet the construction requirements of the construction.5, because of the high strength, can reduce the use of steel, effectively solve the problem of reinforcing steel bars too close, easy to concrete pouring. At the same time, it also reduces the cost of steel transportation and on-site processing.

- Q: What is the process of connecting steel rebars to structural members?

- The process of connecting steel rebars to structural members involves several steps to ensure a secure and reliable connection. Firstly, the rebars, which are typically long, steel bars with ridges or deformations on their surface, need to be accurately positioned within the structural member according to the design specifications. This is often done by using spacers or chairs to maintain the proper spacing between the rebars and the surrounding formwork. Next, the rebars are joined to the structural member using various methods. One common method is through lap splicing, where the rebars are overlapped for a certain distance and then tied together using wire or mechanical connectors. The length of the overlap is determined by engineering calculations to ensure sufficient strength and load transfer. Another method is the use of mechanical couplers, which are pre-fabricated devices that provide a reliable connection between rebars. These couplers are designed to grip the rebars tightly and transfer the load effectively. They offer advantages such as faster installation, reduced labor costs, and improved structural integrity. In addition to splicing, the rebars may also need to be anchored or hooked into the structural member. Anchoring involves extending the length of the rebar beyond the connection point and then bending it back into the concrete, creating a hook shape. This provides additional resistance to the pull-out forces. Throughout the process, it is crucial to ensure that the rebars are clean, free from rust, and properly aligned. Any contaminants or misalignments can weaken the connection and compromise the structural integrity. Therefore, thorough inspection and quality control measures are essential to ensure a successful connection. Overall, the process of connecting steel rebars to structural members involves careful planning, accurate positioning, proper splicing or coupling, and thorough inspection. By following these steps, a strong and durable connection can be achieved, ensuring the safety and stability of the structure.

- Q: Can steel rebars be used in the construction of offshore oil platforms?

- Yes, steel rebars can be used in the construction of offshore oil platforms. Steel rebars are commonly used in construction to reinforce concrete structures and provide additional strength and durability. In the case of offshore oil platforms, steel rebars are used to reinforce the concrete foundations and structures of the platform, helping to withstand the harsh environmental conditions and the weight of the equipment and infrastructure on the platform. The steel rebars are designed to resist corrosion and are typically coated with epoxy or other protective coatings to prevent rusting in the corrosive marine environment. Additionally, steel rebars can be custom-designed to meet the specific requirements of the offshore oil platform, ensuring they provide the necessary strength and stability.

- Q: Can steel rebars be used in the construction of educational institutions?

- Yes, steel rebars can be used in the construction of educational institutions. Steel rebars are commonly used in reinforced concrete structures, including educational buildings, to provide strength and stability to the structure. They are an essential component in the construction of foundations, columns, beams, and slabs, which are all integral parts of educational institutions.

- Q: What are the different types of corrosion protection coatings for steel rebars?

- There are several types of corrosion protection coatings available for steel rebars, each offering different levels of protection and durability. 1. Epoxy Coatings: Epoxy coatings are one of the most common and effective corrosion protection coatings for steel rebars. They provide a thick, durable barrier that prevents moisture and corrosive substances from reaching the steel surface. Epoxy coatings can be applied by spray, brush, or dip methods and provide excellent adhesion and resistance to chemicals. 2. Zinc Coatings: Zinc coatings, such as hot-dip galvanization or zinc-rich paint, are another popular choice for corrosion protection. These coatings create a sacrificial barrier, where the zinc corrodes instead of the steel rebar. Zinc coatings are highly effective in preventing corrosion, even in harsh environments, and can be applied in various thicknesses depending on the level of protection required. 3. Fusion-Bonded Epoxy (FBE) Coatings: FBE coatings are commonly used in underground or submerged applications. These coatings are applied by heating the steel rebar, which causes the epoxy powder to melt and bond to the surface. FBE coatings provide excellent corrosion resistance and are resistant to chemicals, abrasion, and impact. 4. Polymer Coatings: Polymer coatings, such as polyurethane or polyethylene, are often used in high-temperature environments or where chemical resistance is required. These coatings provide a protective barrier that is resistant to UV radiation, abrasion, and chemicals. Polymer coatings can be applied by spray or dip methods and offer good adhesion to the steel surface. 5. Concrete Coatings: In reinforced concrete structures, the concrete itself can act as a corrosion protection coating for the steel rebars. The high alkalinity of concrete creates a protective layer around the steel, known as the passivating layer, which helps prevent corrosion. Additionally, the use of corrosion inhibitors in the concrete mix can enhance the corrosion protection of steel rebars. It is important to select the appropriate corrosion protection coating based on the specific environmental conditions, intended application, and required durability. Consulting with experts or engineers experienced in corrosion protection can help determine the most suitable coating for steel rebars in a given situation.

- Q: Can steel rebars be used in the construction of underground parking garages?

- Yes, steel rebars can be used in the construction of underground parking garages. Steel rebars are commonly used as reinforcement in concrete structures, including underground parking garages, to enhance the overall strength and durability of the construction. The use of steel rebars helps to prevent cracking and structural failures, making them an essential component in underground parking garage construction.

- Q: How are steel rebars used in the construction of water treatment plants?

- Steel rebars are used in the construction of water treatment plants to reinforce the structural integrity of various components, such as concrete foundations, walls, and floors. These rebars help to provide strength and support, ensuring that the water treatment plant can withstand heavy loads, seismic activity, and other environmental factors.

- Q: How do steel rebars contribute to the overall ductility of a structure?

- The overall ductility of a structure is significantly improved by steel rebars in various ways. To begin with, steel rebars possess high flexibility and can endure substantial stress before yielding or breaking. This flexibility enables them to absorb and distribute the applied load, minimizing the risk of sudden failure or collapse. By reinforcing the concrete, rebars assist the structure in withstanding external forces like earthquakes or extreme weather conditions. Furthermore, rebars augment the tensile strength of the concrete. Although concrete is renowned for its impressive compressive strength, its tensile strength is relatively low. When stress is exerted on a structure, rebars aid in resisting tension forces and averting cracking or failure. This ensures that the structure can withstand both compressive and tensile forces, thereby bolstering its overall durability and safety. Moreover, steel rebars also bolster the structural integrity by impeding the propagation of cracks. When a crack initiates in a concrete element, the rebars act as a barrier, restraining the crack's expansion and preventing rapid dissemination. This characteristic of rebars helps to uphold the overall stability and integrity of the structure. Additionally, steel rebars offer a greater degree of flexibility during construction. They can be easily bent, shaped, and joined to meet specific design requirements, granting architects and engineers the ability to create structures that are more aesthetically pleasing and functional. This flexibility also facilitates the construction process by allowing modifications or adjustments to be made without compromising the overall strength or stability of the structure. In conclusion, steel rebars play an indispensable role in enhancing the ductility of a structure. They heighten the tensile strength, absorb and distribute stress, impede crack propagation, and provide flexibility during construction. These properties contribute to the overall durability, safety, and structural integrity of a building or infrastructure, establishing steel rebars as an essential component in contemporary construction practices.

- Q: What is the weight of a typical steel rebar?

- The weight of a typical steel rebar can vary depending on its size and length. However, a commonly used size is a #4 rebar, which has a diameter of 1/2 inch. A #4 rebar typically weighs around 0.67 pounds per foot or 9.5 pounds per 14-foot length. It is important to note that different sizes of steel rebar will have different weights, so it is crucial to consider the specific size and length when determining the weight.

- Q: How are steel rebars bent on-site?

- Steel rebars are bent on-site using specialized equipment such as hydraulic benders or manual bending machines. The rebars are carefully positioned and clamped into the bending machine, which then exerts necessary force to bend them to the desired angle or shape.

Send your message to us

Steel Rebar KS Standard SD400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords