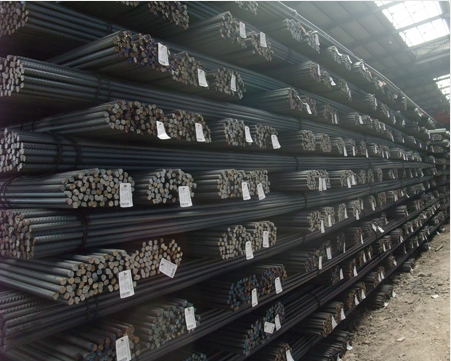

HRB400 Deformed Steel Bar with Leigth 6M,12M,9M

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality HRB400 Deformed Steel Bar with Leigth 6M,12M,9Mat great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

HRB400 Deformed Steel Bar with Leigth 6M,12M,9M are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's HRB400 Deformed Steel Bar with Leigth 6M,12M,9M are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of HRB400 Deformed Steel Bar with Leigth 6M,12M,9M:

Standard | GB | HRB400 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Advantages | exact size, regular package, chemical and mechanical properties are stable. | ||

Type | Hot rolled deformed steel bar | ||

Brand name | DRAGON | ||

Chemical Composition: (Please kindly find our chemistry of our material based on HRB500 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

Usage and Applications of HRB400 Deformed Steel Bar with Leigth 6M,12M,9M:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of HRB400 Deformed Steel Bar with Leigth 6M,12M,9M:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What is the role of steel rebars in preventing cracks in concrete?

- Steel rebars play a crucial role in preventing cracks in concrete by providing tensile strength. As concrete is strong in compression but weak in tension, rebars act as reinforcement, absorbing and distributing the tensile forces that would otherwise cause cracks. By resisting the tension, rebars reinforce the concrete structure, enhance its durability, and ensure it remains stable and crack-resistant over time.

- Q: How do steel rebars contribute to the durability of a structure?

- Steel rebars contribute to the durability of a structure by providing reinforcement and strength to concrete. They help to prevent cracking and structural failure by absorbing and distributing tensile forces, enhancing the overall structural integrity and resilience. Additionally, steel rebars offer resistance to corrosion, ensuring the longevity and durability of the structure.

- Q: Can steel rebars be used in structures with high electrical conductivity requirements?

- No, steel rebars cannot be used in structures with high electrical conductivity requirements as steel is a poor conductor of electricity.

- Q: How are steel rebars used in railway track construction?

- Steel rebars are used in railway track construction to reinforce the concrete sleepers, which are the main support structure for the tracks. The rebars add strength and durability to the sleepers, allowing them to withstand the heavy loads and constant vibrations from passing trains. Additionally, the rebars help to prevent cracking and shifting of the concrete, ensuring a stable and long-lasting railway track.

- Q: What are the guidelines for preventing steel rebars from rusting during construction?

- There are several guidelines to prevent steel rebars from rusting during construction. Firstly, rebars should be stored in a dry area to avoid moisture exposure. Secondly, they should be covered with a waterproof material to protect them from rain or snow. Thirdly, rebars should not be in direct contact with the ground to prevent moisture absorption. Additionally, using epoxy coating or galvanization can provide an extra layer of protection against rust. Lastly, proper curing of concrete should be ensured to minimize the risk of moisture penetration into the rebars.

- Q: How do steel rebars perform in blast-resistant structures?

- Steel rebars perform well in blast-resistant structures due to their high tensile strength and ability to absorb and distribute the energy generated by a blast. The reinforcement provided by rebars helps to strengthen the concrete structure, minimizing the risk of collapse and enhancing the overall resilience of the building. Additionally, steel rebars can be designed and placed strategically to further enhance blast resistance, making them a crucial component in ensuring the safety and durability of such structures.

- Q: What are the different types of steel rebars used in tunnel construction?

- Tunnel construction incorporates a variety of steel rebars, each possessing distinct properties and advantages. 1. Carbon Steel Rebars: These rebars, widely utilized in tunnel construction, boast exceptional strength and durability, rendering them suitable for rigorous applications. Additionally, they offer a cost-effective solution, making them a favored choice for numerous tunnel projects. 2. Stainless Steel Rebars: Tunnel environments exposed to elevated moisture levels, chemicals, or saltwater benefit from stainless steel rebars, which possess corrosion-resistant qualities. Compared to carbon steel rebars, they have a longer lifespan, ultimately reducing maintenance and replacement expenses. 3. Epoxy-Coated Rebars: Epoxy-coated rebars, comprising carbon steel rebars coated with an epoxy layer, provide additional protection against corrosion. As a result, they are well-suited for tunnels situated in harsh environments or those with high chloride content in the soil or water. 4. Galvanized Rebars: To safeguard against corrosion, carbon steel rebars undergo a zinc coating process, resulting in galvanized rebars. They find common use in tunnels where moisture and water exposure are significant concerns. Galvanized rebars exhibit durability and are relatively cost-effective. 5. Fiber-Reinforced Polymer (FRP) Rebars: FRP rebars, composed of composite materials such as fiberglass and resin, deliver benefits such as lightweight construction, corrosion resistance, and an exceptional strength-to-weight ratio. They prove particularly valuable in tunnels where weight reduction is essential, such as in soft ground conditions or when the tunnel structure has load-bearing capacity limitations. It is crucial to consider various factors, including project requirements, environmental conditions, and budgetary constraints, when selecting steel rebars for tunnel construction. Consulting with structural engineers and experts is imperative to determine the most suitable rebars for a specific tunnel project.

- Q: Are steel rebars cost-effective compared to other reinforcement materials?

- Yes, steel rebars are generally considered to be cost-effective compared to other reinforcement materials. Steel has a high strength-to-weight ratio, making it durable and efficient for construction projects. Additionally, steel rebars are readily available, easy to work with, and have a long lifespan, reducing maintenance and replacement costs. Overall, these factors contribute to the cost-effectiveness of steel rebars in comparison to alternative reinforcement materials.

- Q: Can steel rebars be used in modular bridges?

- Yes, steel rebars can be used in modular bridges. Steel rebars are commonly used as reinforcement in concrete structures, including bridges. In modular bridges, where pre-fabricated components are assembled on-site, steel rebars can be used to strengthen the concrete elements and provide additional support for the structure. The rebars are embedded within the concrete elements to enhance their tensile strength and prevent cracking or collapsing under heavy loads. This reinforcement ensures the durability and stability of the modular bridge, making it a reliable and safe transportation solution.

- Q: Can steel rebars be recycled after the demolition of a structure?

- After a structure is demolished, steel rebars can indeed be recycled. In fact, steel is widely recycled around the globe, and rebars are no exception to this trend. Typically, during the demolition process, rebars are separated from other materials like concrete and extracted from the structure. Subsequently, these rebars are gathered and transported to a recycling facility for further processing and melting. The molten steel can then be utilized to produce new rebars or other steel goods, thus decreasing the need for fresh steel production and preserving precious resources. By recycling rebars, not only do we help reduce waste and minimize environmental impact, but we also actively contribute to the circular economy by promoting material reuse.

Send your message to us

HRB400 Deformed Steel Bar with Leigth 6M,12M,9M

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords