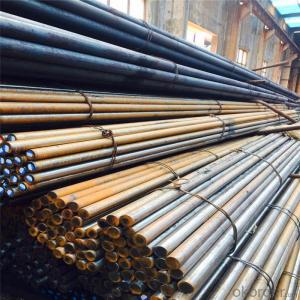

HRB400 hot-rolled reinforced bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HRB400 - Definition

That is the new standard name for HRB400 steel, grade three steel as the old name, as a kind of hot rolled ribbed bar. In the construction industry, three screw steel is the old saying.

Hot rolled ribbed steel grades by HRB and number of yield points minimumcomposition. H, R, B respectively (Hot rolled), hot rolled ribbed steel bar(ribbed), (Bars) the three word's first letter English.

HRB400 - Classification

Hot rolled ribbed steel bar is divided into HRB335 (the old number is 20MnSi),HRB400 (the old No. 20MnSiV, 20MnSiNb, 20Mnti), HRB500 three brands.

Hot rolled bars of fine grains in the grades of hot rolled ribbed bar after Englishabbreviation "fine" English (Fine) the first letter. Such as: HRBF335, HRBF400,HRBF500.

A suitable grade higher requirements for seismic structures: add E in the existing brands after (for example: HRB400E, HRBF400E).

HRB400 - the main purposes

Widely used in houses, bridges, roads and other civil engineeringconstruction.

HRB400 - the main origin

Screw thread steel producers in China are mainly distributed in the north and Northeast China, North China regions such as Shougang, Tang Gang, Xuan Steel, bearing steel, Shanxi Zhongyang steel plant, Baoding Purui the steel,the northeast area such as resistant, Bei Tai, Fushun Steel, these two areas account for about 50% of the total output in the screw thread steel.

The difference between the screw thread steel and round steel bar is provided with longitudinal ribs and transverse ribs surface, usually with two longitudinalribs and transverse ribs along the length direction of the uniform distribution.Screw thread steel belongs to the small steel steel, mainly used in reinforced concrete building components of the skeleton. In use requires a certainmechanical strength, flexural property of welding technology and properties.Screw thread steel billet production raw material for the carbon structure steelsmelting processing sedation or low alloy structural steel, finished steel for the hot rolling, normalizing or hot-rolled state of delivery.

The bending properties of HRB400 - reverse

According to the requirements of the buyer, screw steel for bendingperformance of reverse test.

Reverse bending test bending test bending center diameter than a corresponding increase in rebar diameter. The first positive bending 45 degrees, 23 degrees backward bending, reverse bending 23 degrees after.The reverse bend test, screw steel bending parts shall not generate cracksurface.

HRB400 - surface quality

Screw thread steel surface shall not be permitted to have crack, scarring andfolding.

Screw thread steel surface allows the bumps, but shall not exceed thetransverse rib height, depth of thread other defects on the surface of steel andheight shall not allow the deviation is greater than the location dimension.

HRB400 - dimension, shape, weight and permissible deviations

1 nominal diameter range and recommended diameter

Screw thread steel of nominal diameter range of 6 ~ 25mm, screw steelnominal diameter standard recommended for 6, 8, 10, 12, 16, 20, 25, 32, 40,50mm.

2 surface shape and size of the allowable deviation of rib steel plate

Ribbed Rebar shall meet the following basic rules of transverse ribs:

The included angle beta transverse rib and steel plate axis should not be less than 45 degrees, while the angle of not more than 70 degrees, the screw thread steel on both sides of the transverse rib of relative direction should bethe opposite;

Transverse rib and spacing L not greater than 0.7 times the nominal diameter of the screw thread steel;

Transverse rib side and screw steel surface shall not be less than 45 degreesangle;

The gap between the screw thread steel on both sides of the end of therelative transverse ribs (including longitudinal rib width) should not be greater than the nominal sum of screw thread steel perimeter 20%;

When the screw thread steel nominal diameter is less than 12mm, the relativerib area should not be less than 0.055; some nominal diameter is 14mm and 16mm, the relative rib area should not be less than 0.060; nominal diametergreater than 16mm, the relative rib area should not be less than 0.065.

The length and the allowable deviation of 3

A, length: screw steel usually according to fixed length delivery length, specific delivery length should be specified in the contract; some thread steel to coil at the time of delivery, every dish is a screw steel, allowing each batch of 5%number (less than two wheel is two disc) consisting of two screw thread steel.The wheel weight and diameter of disc by both sides provisions.

B, length tolerance: screw thread steel according to fixed length delivery length when the allowable deviation shall not exceed +50mm.

C, the bending degree and end: allergic straight thread steel bending does not affect the normal use, the total bending degree greater than the total length ofthread steel 40%; screw steel end should be cut straight, local deformationshould not affect the use. [1]

HRB400 - the need to detect project

Inspection items include: serial number of certificate, rolling furnace number,grade, chemical composition (C, Si, Mn, P, V), tensile strength, yield point,percentage elongation, relaxation rate, sectional area, product name,specifications, quantity, date of production, the implementation of standards,receiving unit etc.. Acceptance only after passing inspection will only be forrebar.

- Q: What are the different types of steel rebars used in road construction?

- There are several types of steel rebars used in road construction, each with its own specific characteristics and advantages. Some of the commonly used types include: 1. Mild Steel Rebars: Also known as carbon steel rebars, these are the most commonly used type in road construction. They have a low carbon content and are relatively inexpensive. Mild steel rebars are suitable for general-purpose applications and provide good strength and ductility. 2. High Strength Deformed (HSD) Rebars: These rebars have higher tensile strength compared to mild steel rebars. They are manufactured by subjecting mild steel bars to mechanical treatments, such as hot rolling, quenching, and tempering. HSD rebars are used in areas where higher load-bearing capacity is required, such as bridge construction. 3. Stainless Steel Rebars: These rebars are corrosion-resistant due to their high chromium content. They are especially beneficial in areas with high humidity, coastal regions, or where road construction is exposed to corrosive substances. Stainless steel rebars are more expensive than other types but offer long-term durability. 4. Epoxy-Coated Rebars: These rebars are coated with epoxy to provide protection against corrosion. Epoxy coating acts as a barrier between the steel surface and the environment, preventing the penetration of moisture and corrosive elements. Epoxy-coated rebars are commonly used in concrete pavements to enhance the longevity of the road. 5. Galvanized Rebars: These rebars are coated with a layer of zinc to protect against corrosion. The zinc coating acts as a sacrificial layer, preventing the steel from coming into contact with corrosive elements. Galvanized rebars are commonly used in road construction projects where corrosion resistance is crucial, such as in areas with high levels of moisture or chemical exposure. It is important to select the appropriate type of steel rebars based on the specific requirements of the road construction project. Factors such as load-bearing capacity, environmental conditions, and budget considerations play a significant role in determining the most suitable type of rebar to be used.

- Q: What is the content ratio of the screw steel and manganese steel?

- The standard type of high manganese steel Mn13 steel and Hadfield steel, high manganese steel castings in China National Standard (GB/T5680-1998) grade: ZGMn13-1, ZGMn13-2, ZGMn13-3, ZGMn13-4, ZGMn13-5; ASTM (ASTMA128/A128M-1993) standard austenitic manganese steel casting steel are: ASTM-A (UNS-J9110.

- Q: Can steel rebars be used in road and bridge construction?

- Yes, steel rebars can be used in road and bridge construction. Steel rebars provide structural integrity and strength to reinforce concrete structures, making them suitable for use in the construction of roads and bridges. They enhance the durability, load-bearing capacity, and resistance to cracking and deformation in these infrastructure projects.

- Q: What are the guidelines for proper curing of concrete structures with steel rebars?

- To ensure the strength, durability, and longevity of concrete structures with steel rebars, it is crucial to properly cure them. Here are some guidelines to consider: 1. Moisture Control: Maintaining a moist environment around the concrete structure is vital during the curing process. This can be done by either covering the concrete surface with a plastic sheet or using a curing compound. These measures prevent water evaporation, which can lead to shrinkage, cracking, and reduced strength. 2. Curing Duration: The duration of curing depends on factors like the concrete mix, environmental conditions, and the complexity of the structure. Generally, curing should last at least 7 days to allow sufficient strength development. However, for structures with steel rebars, it is advisable to extend the curing period to 14-28 days to ensure proper hydration and bonding between the concrete and steel. 3. Temperature Control: Temperature plays a crucial role in the curing process. Avoiding extreme temperature fluctuations is important as they can negatively affect concrete strength and durability. High temperatures can cause rapid drying and shrinkage, leading to cracks. Freezing temperatures can impede hydration. Therefore, maintaining a moderate and consistent temperature is essential for effective curing. 4. Protection from External Factors: During the curing period, concrete structures should be shielded from external factors that can compromise their integrity. This involves avoiding direct sunlight, rain, strong winds, or any adverse weather conditions. Additionally, protecting the concrete from potential damage caused by construction activities or heavy loads is vital. 5. Regular Inspection and Maintenance: Regularly inspecting the concrete structure throughout the curing process is necessary to identify issues like cracks, honeycombing, or inadequate curing. Any problems should be addressed promptly to prevent further damage. Once the curing process is complete, implementing a proper maintenance plan is crucial to ensure long-term durability and structural integrity. By adhering to these guidelines, the proper curing of concrete structures with steel rebars can be achieved, resulting in strong, durable, and dependable construction.

- Q: What are the different types of steel rebars used in parking structures?

- The different types of steel rebars commonly used in parking structures include conventional carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. These rebars are chosen based on their specific properties and resistance to corrosion, ensuring the structural integrity and longevity of the parking structure.

- Q: Grade 1, grade three, grade two, steel, wire rod, round bar

- Round steel is a solid strip of steel whose cross section is round. The specifications are expressed in millimeters of diameter, such as "50", which means a round bar of 50 millimeters in diameter. Round bar is divided into three parts: hot rolling, forging and cold drawing. Standard Specification for hot rolled round steel is 5.5-250 mm. Among them, 5.5-25 mm small round bars are mostly supplied by straight strips. They are used as reinforcing bars, bolts and various mechanical parts. They are more than 25 millimeters of round steel. They are mainly used in the manufacture of mechanical parts or seamless steel tube billets.

- Q: Can steel rebars be used in structures with high aesthetic requirements?

- Yes, steel rebars can be used in structures with high aesthetic requirements. While steel rebars are primarily used for their strength and durability, they can also be designed and incorporated in a way that meets aesthetic requirements. Rebars can be shaped, bent, or painted to match the desired aesthetic of the structure. Additionally, they can be hidden within the structure or covered by other materials to maintain a clean and visually appealing appearance. With careful planning and design, steel rebars can be successfully used in structures with high aesthetic requirements without compromising their functionality or visual appeal.

- Q: What are the different methods of reinforcing concrete structures using steel rebars?

- There are several methods of reinforcing concrete structures using steel rebars. These include placing the rebars in a grid pattern to provide overall strength and support, using stirrups or ties to hold the rebars in place and prevent them from moving, using dowel bars to connect two separate concrete elements, and using anchor bolts or hooks to secure the rebars to the existing structure. Additionally, steel mesh or fiber reinforcement can be used to enhance the overall durability and resilience of the concrete structure.

- Q: What are the different types of steel rebars used in underground structures?

- There exists a variety of steel rebars that are frequently utilized in underground structures, each possessing its own unique properties and characteristics. The decision regarding which type of rebar to use depends on a multitude of factors, such as the project's specific requirements, the necessary load-bearing capacity, and the environmental conditions of the underground structure. To begin with, there are mild steel rebars, which are also referred to as carbon steel rebars. These are the most commonly employed type due to their affordability and widespread availability. Mild steel rebars possess a low carbon content and offer commendable tensile strength, rendering them suitable for general construction purposes in underground structures. Next, we have high strength deformed (HSD) rebars, which are crafted from carbon steel and undergo additional heat treatment processes. These processes result in heightened yield strength and improved resistance to corrosion. HSD rebars find common usage in areas with high seismic activity or in situations where an increased load-bearing capacity is required. Furthermore, there are epoxy-coated rebars, which are specifically designed to combat aggressive environments that underground structures can be exposed to, including moisture and chemicals. By applying an epoxy coating to the surface of the rebar, enhanced corrosion resistance is achieved. This coating acts as a protective barrier, reducing the risk of corrosion and prolonging the lifespan of the rebar. Stainless steel rebars also play a significant role in underground structures. They possess an exceptional resistance to corrosion, which makes them ideal for usage in harsh underground environments. They prove particularly beneficial in structures where chloride or other corrosive agents are present, such as underground water treatment facilities or sewer systems. Lastly, there are galvanized rebars, which are coated with a layer of zinc to provide corrosion protection. This type of rebar is commonly employed in underground structures where moisture or exposure to corrosive elements is a concern. The zinc coating acts as a sacrificial layer, corroding in place of the rebar and extending its service life. In conclusion, underground structures employ various types of steel rebars, including mild steel rebars, high strength deformed rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. The selection of the appropriate rebar type is contingent upon the specific requirements and environmental conditions of the underground structure.

- Q: Can steel rebars be used in combination with other reinforcement materials?

- Yes, steel rebars can be used in combination with other reinforcement materials in construction projects. Steel rebars are commonly used in reinforced concrete structures to provide tensile strength and enhance the overall structural integrity. However, in some cases, additional reinforcement materials may be required to meet specific design requirements or address unique construction challenges. For instance, in high seismic areas, where flexibility and ductility are crucial, steel rebars can be combined with other materials such as fiber-reinforced polymer (FRP) bars or carbon fiber-reinforced polymer (CFRP) strips. These materials offer enhanced strength and flexibility, helping to improve the structure's resistance to seismic forces. Moreover, in situations where corrosion is a concern, steel rebars can be used in combination with corrosion-resistant materials like stainless steel rebars or epoxy-coated rebars. These materials create a protective barrier, preventing the steel rebars from coming in direct contact with moisture and corrosive agents. Additionally, in some specialized applications such as precast concrete elements or composite structures, steel rebars can be used alongside other reinforcement materials like prestressed tendons or structural fibers. This combination allows for the redistribution of loads and ensures optimal structural performance. In summary, steel rebars can be effectively combined with other reinforcement materials to meet specific construction requirements, enhance structural performance, and address challenges related to seismic activity, corrosion, or specialized applications.

Send your message to us

HRB400 hot-rolled reinforced bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords