High Quality Deformed Steel Rebars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000tons/year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Deformed Steel Rebars:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Packing | Export standard packing: wrapped by wire rod in bundles | ||

Each bundle weight | 2-3MT, or as required | ||

Trade terms | FOB, CFR, CIF | ||

Payment terms | TT payment in advance or Irrevocable LC at sight. | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

Chemical Composition: (Please kindly find our chemistry of our material based on JIS as below for your information)

JISG3112 SD390 | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.22 | 1.38 | 0.4 | 0.014 | 0.022 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

620 | ≥400 | 21 | |||

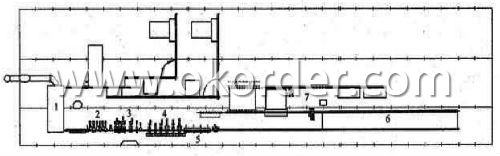

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of High Quality Deformed Steel Rebars:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of High Quality Deformed Steel Rebars:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Price: Keep lower operating costs so as to offer competitive price for our clients

Deformed Steel Rebars according to Korean standard

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: What are the common applications of steel rebars?

- Steel rebars are commonly used in the construction industry for reinforcing concrete structures such as buildings, bridges, highways, and dams. They provide strength, durability, and stability to the concrete, enhancing its load-bearing capacity and resistance to tension and bending forces.

- Q: What is the role of steel rebars in the construction of multi-level car parks?

- The role of steel rebars in the construction of multi-level car parks is to provide reinforcement and strength to the concrete structures. Rebars are incorporated within the concrete to enhance its tensile strength, durability, and resistance to cracking or collapsing under heavy loads. They help distribute the weight and stress evenly, ensuring the structural integrity of the car park and ensuring it can safely support multiple levels of vehicles.

- Q: What are the different types of steel rebars used in road constructions?

- Road constructions commonly utilize various types of steel rebars. These include: 1. Mild steel rebars: These are the most frequently employed rebars in road constructions. They consist of low carbon steel and possess a smooth surface. Mild steel rebars are renowned for their durability and strength, making them suitable for a range of road construction applications. 2. High-strength rebars: Crafted from high-strength steel, these rebars possess a greater yield strength compared to mild steel rebars. They are utilized in road constructions that require enhanced load-bearing capacity, such as bridges and highways. 3. Epoxy-coated rebars: These rebars are coated with epoxy resin to enhance their resistance to corrosion. They are commonly used in road constructions in areas exposed to moisture and chemicals, such as coastal regions. 4. Galvanized rebars: These rebars feature a zinc coating that provides protection against corrosion. They are particularly suitable for road constructions in regions with high humidity or a high risk of corrosion. 5. Stainless steel rebars: Constructed from stainless steel, these rebars exhibit exceptional corrosion resistance. They are frequently employed in road constructions that necessitate long-term durability and resistance to corrosion, such as tunnels and underground structures. Selecting the appropriate type of steel rebar for road constructions is crucial and should be based on specific project requirements, including load-bearing capacity, exposure to corrosion, and environmental conditions. Consulting structural engineers and adhering to local construction codes and standards is essential to ensure the successful implementation of road construction projects.

- Q: Are there any health and safety concerns related to steel rebars?

- Yes, there are potential health and safety concerns related to steel rebars. Handling and working with steel rebars can pose risks such as cuts, injuries from falling or displaced rebars, and musculoskeletal disorders due to heavy lifting or repetitive movements. Additionally, workers may be exposed to hazards during the fabrication process, such as welding fumes or noise pollution. Adequate safety measures, including personal protective equipment and proper training, should be implemented to mitigate these risks and ensure a safe working environment.

- Q: What is the role of steel rebars in preventing concrete shrinkage?

- Steel rebars play a crucial role in preventing concrete shrinkage. When concrete cures, it tends to shrink and undergoes volumetric changes. This shrinkage can lead to the development of cracks, compromising the structural integrity and durability of the concrete. Rebars, which are steel reinforcement bars, are embedded within the concrete to counteract this shrinkage. The primary function of rebars is to provide tensile strength to the concrete, as concrete is weak in tension but strong in compression. By adding rebars, the concrete becomes reinforced and gains the ability to withstand tensile forces. During the curing process, the concrete shrinks, but the presence of rebars helps distribute the stress and strain caused by this shrinkage. The rebars act as a framework, resisting the shrinkage-induced forces and preventing the formation of significant cracks. Instead of the concrete trying to shrink uniformly across its entire surface, the rebars help to control and limit the shrinkage, minimizing the potential for cracking. Additionally, rebars also contribute to the overall structural stability of the concrete. They enhance the load-bearing capacity, improve resistance against external forces such as earthquakes or heavy loads, and increase the flexural strength of the concrete. By reinforcing the concrete with rebars, the structure becomes more resistant to deformation, ensuring its longevity and safety. In summary, steel rebars play a critical role in preventing concrete shrinkage by providing tensile strength and distributing stress and strain. They reinforce the concrete, enhance its structural stability, and minimize the risk of cracking, thereby ensuring the durability and integrity of concrete structures.

- Q: How do steel rebars improve the load-carrying capacity of concrete?

- Steel rebars improve the load-carrying capacity of concrete by providing additional tensile strength. When concrete is subjected to heavy loads or forces, it tends to crack under tension. The inclusion of steel rebars within the concrete helps to counteract this weakness by absorbing the tensile forces and distributing them throughout the structure. This reinforcement enhances the overall durability and structural integrity of the concrete, allowing it to bear heavier loads without failing.

- Q: How do steel rebars affect the overall durability of marine structures?

- Steel rebars greatly enhance the overall durability of marine structures. These reinforced bars provide additional strength and resilience, making the structures more resistant to corrosion, fatigue, and the constant exposure to harsh marine environments. By reinforcing the concrete, steel rebars increase the structural integrity, preventing cracks and enhancing load-bearing capacity, ensuring that marine structures can withstand the forces of waves, tides, and weather conditions, thereby prolonging their lifespan.

- Q: How do steel rebars contribute to the structural integrity of a building?

- Steel rebars play a crucial role in enhancing the structural integrity of a building. These reinforcing bars, commonly known as rebars, are typically made from steel and are used to provide strength and stability to concrete structures. They are embedded within the concrete to create a composite material that can withstand various types of forces and loads. Firstly, rebars help to distribute and transfer loads throughout the structure. When a building is subjected to external forces such as wind, earthquakes, or heavy loads, the rebars act as a reinforcement by absorbing and dispersing these forces. By distributing the load over a larger area, they prevent concentrated stress points that could potentially lead to structural failure. Secondly, rebars assist in preventing cracks and fractures in the concrete. Concrete, although highly durable in compression, is weak in tension. Steel rebars, with their high tensile strength, counteract this weakness by resisting the tensile forces that may cause the concrete to crack or fail. By reinforcing the concrete, rebars ensure that the structure remains intact and can withstand various types of stresses. Moreover, rebars increase the overall durability and lifespan of a building. By providing additional strength and stability, they reduce the likelihood of structural damage, ensuring that the building can withstand the test of time. This is particularly important in areas prone to natural disasters, where the strength of a building can be a matter of life and death. Lastly, steel rebars contribute to the overall safety of a building. By reinforcing the structure, they increase its ability to withstand extreme events such as earthquakes or heavy impacts. This not only protects the occupants of the building but also reduces the risk of collateral damage to surrounding structures. In conclusion, steel rebars are essential components in construction that significantly contribute to the structural integrity of a building. Their ability to distribute loads, prevent cracks, increase durability, and enhance safety make them an indispensable element in modern construction practices.

- Q: What are the guidelines for handling and installing steel rebars in construction sites?

- The guidelines for handling and installing steel rebars in construction sites typically include the following: 1. Storage: Steel rebars should be stored on a flat and dry surface, preferably on elevated racks to prevent contact with the ground and avoid rusting or damage. 2. Transportation: Rebars should be moved using appropriate lifting equipment, such as cranes or forklifts, to prevent excessive bending or mishandling. 3. Inspection: Rebars should be inspected for any defects, such as bends, cracks, or excessive rust, before installation. Damaged rebars should not be used. 4. Cutting and bending: Rebars should be cut and bent using appropriate tools and equipment, following the specifications and dimensions provided in the construction plans. 5. Placement: Rebars should be placed accurately and securely within the concrete structures, ensuring proper alignment and spacing as per the design requirements. 6. Tying: Rebars should be securely tied together using wire or approved tying methods at the intersections to maintain the desired positions during concrete pouring. 7. Embedment: Rebars should be properly embedded within the concrete to ensure sufficient coverage, typically complying with the minimum concrete cover specified in the design. 8. Safety: Adequate personal protective equipment (PPE), such as gloves and safety boots, should be worn by workers during rebars handling and installation to prevent injuries. It is important to note that specific construction projects and local regulations may have additional guidelines or requirements for handling and installing steel rebars. Therefore, it is crucial to refer to the project specifications and consult with relevant experts or authorities for comprehensive guidelines.

- Q: How are steel rebars protected during concrete pouring?

- Steel rebars are typically protected during concrete pouring by using a layer of epoxy coating or corrosion-resistant paint. This protective layer acts as a barrier between the rebar and the concrete, preventing direct contact and reducing the risk of corrosion. Additionally, plastic or foam covers can be used to shield the rebars from the wet concrete, ensuring proper adhesion and preventing damage during the pouring process.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; East Asia; Middle east |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 40%-60% |

| No.of Employees in Trade Department | 21-60 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 850,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

High Quality Deformed Steel Rebars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000tons/year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords