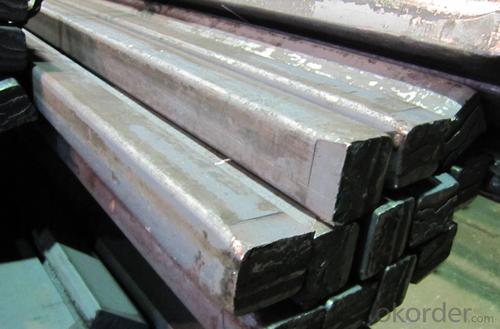

Q235/3SP 150MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 150MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 150MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 150MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 150MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 150MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Are steel billets used in the production of household goods?

- No, steel billets are typically not used in the production of household goods. They are usually used as raw materials in steel mills for the production of various steel products, such as bars, rods, pipes, and structural components.

- Q: Can steel billets be used in the production of construction machinery?

- Yes, steel billets can be used in the production of construction machinery. Steel billets are semi-finished products that can be further processed to manufacture various components and parts required in construction machinery. These billets provide a reliable and strong material, making them suitable for the construction industry's heavy-duty applications.

- Q: Are steel billets used in the production of sporting goods?

- Yes, steel billets are commonly used in the production of sporting goods. They are often utilized to create various components such as the shafts of golf clubs or the frames of bicycles. Steel billets provide durability and strength to these sporting goods, making them suitable for intense physical activity.

- Q: Can steel billets be used in the production of appliances?

- Yes, steel billets can be used in the production of appliances. Steel billets are semi-finished products that are typically used for further processing into various shapes and sizes. In the case of appliances, steel billets can be used as the raw material for manufacturing components such as frames, panels, and other structural parts. Steel is a versatile and durable material that offers strength, stability, and resistance to corrosion, making it suitable for use in appliances that require robust construction. Additionally, steel can be easily molded and shaped to meet the specific design requirements of different appliances, making it a preferred choice in the manufacturing process.

- Q: What is the active carbon. What is the difference with the charcoal?

- This decision of the activated carbon has Good adsorption of metal ions, adsorption, wastewater and waste gas in the harmful gases, organic pollutants, such as pigment. Application of activated carbon also requires high mechanical strength, good abrasion resistance, its structure to stabilize, adsorption energy required, to facilitate the regeneration. The active carbon used for oil, beverage, food, drinking water, decolorization, deodorization, gas separation, solvent recovery and air conditioning, adsorbent is used as a catalyst carrier and a gas mask. Charcoal is made from trees and dry, is a kind of fuel. Soil general burn charcoal, is placed in a kiln inner wood, after the ignition, when he arrived a certain temperature, closed kiln inlet, let the heat get distillation of wood and charcoal. To serve the people of Zhang Side is burning charcoal, charcoal kiln collapsed when.1 died

- Q: What are the different types of mechanical property testing methods for steel billets?

- Some different types of mechanical property testing methods for steel billets include tensile testing, hardness testing, impact testing, and fatigue testing. Tensile testing measures the strength and ductility of the material by applying a pulling force until it breaks. Hardness testing measures the resistance of the material to penetration or indentation. Impact testing evaluates the material's ability to absorb energy under high rates of loading. Fatigue testing assesses the material's resistance to failure under cyclic loading conditions.

- Q: What are the different types of extrusion processes used for shaping steel billets?

- The different types of extrusion processes used for shaping steel billets include hot extrusion, cold extrusion, direct extrusion, indirect extrusion, and hydrostatic extrusion.

- Q: How are steel billets used in the manufacturing of pumps and compressors?

- Pumps and compressors rely heavily on steel billets, a crucial raw material for their manufacturing process. These semi-finished steel forms are transformed into different components and parts of these devices. To prepare steel billets for shaping, the initial step involves heating them to a high temperature to make them malleable. Once heated, the billets go through various metalworking techniques like forging, rolling, or extrusion. By subjecting them to these processes, the billets are converted into the desired shapes and sizes required for specific pump and compressor components. In pump manufacturing, steel billets are utilized to fabricate impellers, responsible for fluid movement and circulation. The billets are shaped according to the impeller design through machining or casting procedures. Similarly, for compressors, steel billets are used to create vital components like cylinders, pistons, and connecting rods, which facilitate gas compression and movement. The preference for steel billets in pump and compressor manufacturing stems from their advantageous properties, such as strength, durability, and corrosion resistance. These properties are vital for ensuring the efficiency and longevity of these mechanical devices, especially when they operate under high pressures, temperatures, and harsh working conditions. In conclusion, steel billets play a fundamental role in the manufacturing process of pumps and compressors. They provide the necessary raw material for shaping and creating various components that enable these devices to function effectively.

- Q: How are steel billets used in the production of mining equipment?

- Due to their strength, durability, and versatility, steel billets are crucial for the production of mining equipment. These billets are typically made by pouring molten steel into a mold, resulting in a solid rectangular shape. They are then used as raw material in the manufacturing process of mining equipment. Mining operations require robust and reliable components for equipment such as excavators, bulldozers, and crushers, to withstand harsh conditions and heavy loads. Steel billets provide the necessary structural integrity and toughness, ensuring efficient and safe equipment operation. Once obtained, steel billets undergo various techniques such as forging, machining, and welding to transform them into specific parts and components. Forging can create heavy-duty gears, shafts, and axles, which are essential for mining equipment. Machining steel billets allows for custom-made components that fit seamlessly into mining equipment. This process involves cutting, drilling, and milling to create parts like buckets, cutting edges, and chassis. In addition, welding steel billets together creates complex structures and ensures equipment integrity and strength. This is particularly important in mining equipment construction, where safety and reliability are paramount. In conclusion, steel billets are vital for producing mining equipment as they provide the necessary raw material. Their strength, durability, and versatility allow for the creation of robust and reliable components that can withstand the demanding conditions of mining operations.

- Q: After processing to the color coating board, is there a fare increase of 1000?The price of galvanized coil is about +350 per ton of cold-rolled steel at present What about the cost of billet to cold rolling?What is the final cost of making the color coated sheet? How do you figure that?

- The cost of billet to cold rolling is about 1000Galvanized to color coated sheet costs vary greatly, generally around 300, a high of 500

Send your message to us

Q235/3SP 150MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords