PVC Membrane Reinforcement of Polyester for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Membrane Reinforcement of Polyester for Waterproof System

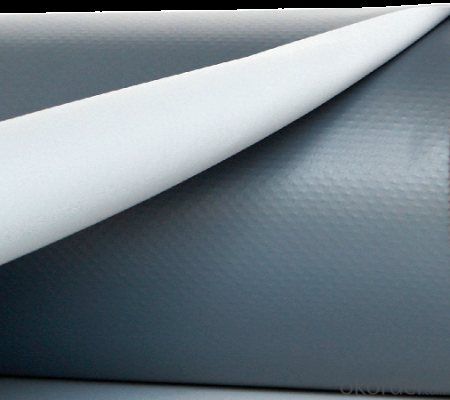

Description Of PVC Membrane Reinforcement fo Polyester for Waterproof System:

1. PVC Membrane Reinforcement fo Polyester is made from PVC and poliester , which is for waterproofing of exposed and non-exposed applications.

2. PVC Membrane Reinforcement fo Polyester adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. PVC Membrane Reinforcement fo Polyester is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of PVC Membrane Reinforcement fo Polyester:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of PVC Membrane Reinforcement fo Polyester:

Material | PVC |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m |

Thick | 1.2mm, 1.5mm, |

Type | Reinforcement fo Polyester |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of PVC Membrane Reinforcement fo Polyester:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

IMages of PVC Membrane Reinforcement fo Polyester:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can a waterproofing membrane be used in areas with high levels of salt or saltwater exposure?

- Yes, a waterproofing membrane can be used in areas with high levels of salt or saltwater exposure. However, it is important to choose a membrane specifically designed to withstand such conditions. Certain waterproofing membranes are specifically formulated to be resistant to salt and saltwater exposure, preventing any potential damage or degradation. These membranes are typically made with materials that are highly resistant to corrosion and have enhanced durability. It is crucial to consult with a professional to ensure the correct type of waterproofing membrane is selected for high salt or saltwater exposure areas to ensure long-term effectiveness and protection.

- Q: Can waterproofing membranes be used on concrete tanks?

- Yes, waterproofing membranes can be used on concrete tanks. They provide a protective barrier against water penetration, preventing leakage and water damage.

- Q: Can a waterproofing membrane be used on precast brick block surfaces?

- Yes, a waterproofing membrane can be used on precast brick block surfaces. The membrane acts as a barrier to prevent water penetration and can help protect the precast brick blocks from moisture damage.

- Q: Can a waterproofing membrane be used in high-traffic areas, such as decks or balconies?

- Yes, a waterproofing membrane can be used in high-traffic areas such as decks or balconies. Waterproofing membranes are designed to provide protection against water damage and can withstand regular foot traffic. They are durable and can effectively prevent water penetration, making them suitable for use in areas that experience heavy use.

- Q: Can a waterproofing membrane be used for tunnels and underground structures?

- Tunnels and underground structures necessitate the use of a waterproofing membrane to combat water infiltration and safeguard against potential water damage. Such membranes are commonly employed in construction to create a barrier against water and are particularly vital in these situations due to the increased risk of water ingress from surrounding soil and groundwater. The integrity and longevity of the infrastructure rely on waterproofing membranes in these environments. Waterproofing membranes designed for tunnels and underground structures are specifically engineered to endure the unique challenges presented by these settings. Typically composed of resilient and flexible materials like bitumen, PVC, or EPDM, they effectively resist water pressure and provide long-lasting protection. Furthermore, these membranes are often reinforced with multiple layers or fabrics to enhance strength and resistance against punctures or tears. The meticulous process of applying waterproofing membranes in tunnels and underground structures involves thorough cleaning and preparation of surfaces such as walls and floors to ensure proper adhesion of the membrane. Multiple layers are then applied to achieve complete coverage and a seamless seal. Special attention is paid to critical areas such as joints, corners, and penetrations to eliminate potential weak points. The utilization of a waterproofing membrane effectively shields tunnels and underground structures from water intrusion, groundwater pressure, and potential moisture-induced damage. This preserves the structural integrity of the infrastructure, prevents water-related issues like leaks, corrosion, or deterioration, and guarantees the safety and functionality of the tunnel or underground facility.

- Q: Does a waterproofing membrane prevent water infiltration through concrete or other building materials?

- Indeed, the primary purpose of a waterproofing membrane is to thwart the ingress of water into concrete or other construction materials. It serves as a safeguarding shield that is administered onto the material's surface, creating a layer impervious to water. The composition of this membrane can vary, encompassing substances like bitumen, rubberized asphalt, or liquid polymers. Once installed with precision, it effectively averts water infiltration, thereby safeguarding the edifice against potential water-induced harm or moisture-related predicaments.

- Q: Can a waterproofing membrane be used for a retaining wall drainage?

- Yes, a waterproofing membrane can be used for retaining wall drainage. A waterproofing membrane is typically used to prevent water from penetrating through a structure, such as a basement or foundation. However, it can also be used in the construction of retaining walls to provide a barrier against water seepage. Retaining walls are designed to hold back soil and prevent erosion, but they can be susceptible to water damage if not properly constructed. Water seepage can cause pressure build-up behind the wall, leading to structural issues over time. By installing a waterproofing membrane on the backside of the retaining wall, it acts as a barrier to prevent water from infiltrating the soil and accumulating behind the wall. In addition to preventing water seepage, a waterproofing membrane can also aid in the drainage of water away from the retaining wall. By incorporating drainage systems, such as weep holes or French drains, in conjunction with the membrane, water can be directed away from the wall, reducing hydrostatic pressure and potential damage. It is important to note that while a waterproofing membrane can be used for retaining wall drainage, it is crucial to ensure proper installation and compatibility with the specific retaining wall system and conditions. Consulting with a professional engineer or contractor experienced in the construction of retaining walls is recommended to ensure the best approach for your specific project.

- Q: Can a waterproofing membrane be used in new construction?

- Yes, a waterproofing membrane can be used in new construction. In fact, it is often recommended to install a waterproofing membrane during the construction phase to provide an added layer of protection against water damage. Waterproofing membranes are typically applied to the exterior foundation walls and basement floors to prevent water infiltration and to create a barrier against moisture. This can help to prevent issues such as leaks, mold, and structural damage in the future. Additionally, waterproofing membranes can also be used in other areas of a new construction project, such as roofs, balconies, and bathrooms, to ensure long-lasting waterproofing protection. Overall, using a waterproofing membrane in new construction can help to prolong the lifespan of the building and provide peace of mind for the occupants.

- Q: Can a waterproofing membrane be used for planter boxes or green roofs?

- Yes, a waterproofing membrane can be used for planter boxes or green roofs. It helps to prevent water leakage and protect the underlying structure.

- Q: Can a waterproofing membrane be used in roofs?

- Yes, a waterproofing membrane can be used in roofs. Waterproofing membranes are often used in roofing systems to provide a protective barrier against water infiltration, preventing leaks and water damage.

Send your message to us

PVC Membrane Reinforcement of Polyester for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords