PVC Waterproofing Membrane for Underground Leakage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

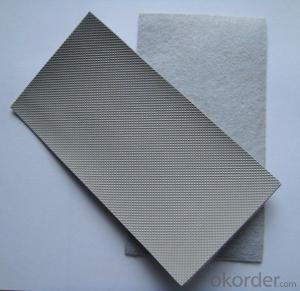

Introduction of PVC Waterproofing Membrane:

PVC Self-adhesive Waterproof Membrane is a kind of synthetic polymer waterproof membrane which made from polymer self-adhesive polymer, uses Polymer sheet(PVC) as the original source. It has high tensile strength, perfect elongation, excellent resistance to punture and tear, the greatest feature the material is: Concrete can be pasted directly on the membrane surface, after the concrete has been setted, bond strength of membrane and concrete is greater than 2.0Mpa so as to solve the problem of membrane channeling water and leakage.

Features

1.High Tensile strength, excellent resistance to tear and puncture.

2.Strong adhesion with the concrete, effectively prevent the emergence of a single polymer sheet phenomenon of channeling water.

3.Lap with pre- self-adhesive side lap to ensure the seamless of waterproof system.

4.Perfect resistance to acid&alkali,weather and aging.

5.Simple operation, High work efficiency, Low cost.

6.Non toxic, tasteless and be environmentfriendly.

Scope of Application

Large-scale underground structures.

Surface of concrete slabs for planting.

For Roads, Rails, Subway tunnels projects.

For reservoirs, canals, dams and other water conservancy projects.

For air defense, military facilities waterproof projects.

Construction technology

Tunnels, bridges should use polmer sheet welding lap joints. Firstly, pre-paved polymer sheet side of polymer self-adhesive composite waterproof membrane toward the base, and fix it with dedicated pieces of machine, double lap weld seam welding machine should be used for lap joints. Tear off insulation paper, band reinforced concrete directly, self-adhesive waterproof membrane will adhere to the main body of concrete structure closely to achieve full adhesion.

General building underground projects should use self-adhesive overlap method. Basement bottom: pre-laying the membrane on cushion firstly(polymer sheet face down), tear off reserved isolation paper of lap joints self-adhesive side and can be sealed when paste directly; tear off isolation paper of self-adhesive waterproof layer, structural concrete, the membrane will anti-stick to the concrete structure to form dense waterproof system.

Basement side wall, Surface of concrete slabs for planting: attach the self-adhesive material side to the base surface directly, tear off reserved isolation paper of lap joints self-adhesive side. Side wall shall be fixed with dedicated pieces of machine.

Half header treatment:Wether horizontal half header or vertical half header, which should be sealed with sealant, membrane in the elevation without groove half header, it shall be fixed with metal straps firstly, then seal the top hole of metal straps and fixed screw with sealant.

Specification of PVC Waterproofing Membrane:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Remark: The property of artificial weathering might not be applicable to non-exposed product | |||

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on chrome surfaces?

- No, a waterproofing membrane is not suitable for use on chrome surfaces as it is designed to be used on porous materials such as concrete or wood to prevent water penetration. Chrome surfaces are already water-resistant, so applying a waterproofing membrane would be unnecessary and may damage the chrome finish.

- Q: Can a waterproofing membrane be used on planter boxes?

- Yes, a waterproofing membrane can be used on planter boxes to prevent water leakage and protect the structure of the boxes.

- Q: Can a waterproofing membrane be used in below-grade applications?

- Yes, a waterproofing membrane can be used in below-grade applications. Below-grade applications refer to areas below ground level, such as basements or underground structures. Using a waterproofing membrane in these areas is crucial to prevent water infiltration, as these areas are more susceptible to moisture and water damage. The waterproofing membrane acts as a barrier, preventing water from seeping through the walls or floors and causing structural damage or moisture-related issues. It helps to keep the below-grade areas dry, thereby protecting the integrity of the building and ensuring a safe and habitable environment. Waterproofing membranes designed for below-grade applications are typically made of durable materials that are resistant to water and have high tensile strength to withstand ground pressure. They are specifically designed to adhere to various substrates like concrete, ensuring a tight and secure seal. Overall, using a waterproofing membrane in below-grade applications is essential for maintaining a moisture-free and structurally sound space.

- Q: Can a waterproofing membrane be used for a shopping mall underground parking?

- In a shopping mall underground parking, it is possible to use a waterproofing membrane. Due to their below-ground location, underground parking structures are at a high risk of water infiltration. To prevent this, a waterproofing membrane is typically installed during the construction process. This membrane acts as a barrier, stopping water from seeping into the parking structure and causing damage. It is designed to withstand the pressure from the surrounding soil and any potential hydrostatic forces. Moreover, a waterproofing membrane can also help reduce the risk of moisture-related issues like mold or mildew, which can compromise the safety and integrity of the parking structure. Therefore, incorporating a waterproofing membrane is a widely used and effective solution to ensure the long-term durability and functionality of underground parking facilities in shopping malls.

- Q: Can a waterproofing membrane be used for underground parking garages?

- Yes, a waterproofing membrane can be used for underground parking garages. In fact, it is highly recommended to use a waterproofing membrane in these types of structures to prevent water infiltration and damage. Underground parking garages are prone to water seepage from the surrounding soil, and the constant exposure to moisture can lead to structural deterioration, corrosion of steel reinforcements, and the growth of mold and mildew. A waterproofing membrane acts as a barrier, preventing water from penetrating the walls and floors of the garage. It is applied to the exterior surfaces of the structure, providing a protective layer that keeps the interior dry and free from water-related issues. The membrane should be selected based on the specific requirements of the project, considering factors such as the type of construction materials, the groundwater conditions, and the anticipated level of water pressure. Additionally, proper installation techniques and regular maintenance are crucial to ensure the long-term effectiveness of the waterproofing system.

- Q: Can a waterproofing membrane be used in conjunction with concrete repair or restoration?

- Yes, a waterproofing membrane can be used in conjunction with concrete repair or restoration. In fact, it is often recommended to use a waterproofing membrane as a protective layer over repaired or restored concrete surfaces. This is because concrete repair or restoration may involve the removal of damaged or deteriorated areas, which can compromise the waterproofing properties of the original concrete. By applying a waterproofing membrane, you can ensure that the repaired or restored concrete remains protected against water intrusion, which can lead to further damage and deterioration. Additionally, the waterproofing membrane can also help to enhance the overall durability and longevity of the concrete structure.

- Q: Are waterproofing membranes resistant to gasoline vapors?

- Yes, waterproofing membranes are generally resistant to gasoline vapors. They are designed to create a barrier against moisture and other liquids, including gasoline and its vapors.

- Q: Are waterproofing membranes resistant to acid exposure?

- The resistance of waterproofing membranes to acid exposure can differ depending on the specific type of membrane used. Certain waterproofing membranes are engineered to withstand acid exposure, whereas others may not have the same resistance. Therefore, it is of utmost importance to meticulously choose the suitable waterproofing membrane for the particular application and environment where acid exposure could be an issue. Seeking guidance from manufacturers or industry professionals is also recommended in order to determine the most effective waterproofing membrane solution for areas prone to acid.

- Q: How much does a waterproofing membrane cost?

- The cost of a waterproofing membrane can vary depending on factors such as the type of membrane, the size of the area to be waterproofed, and the brand. On average, you can expect to spend anywhere from $1 to $5 per square foot for the material and installation.

- Q: Can a waterproofing membrane be used in crawl spaces?

- Yes, a waterproofing membrane can be used in crawl spaces to prevent moisture infiltration and protect the space from water damage.

Send your message to us

PVC Waterproofing Membrane for Underground Leakage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords