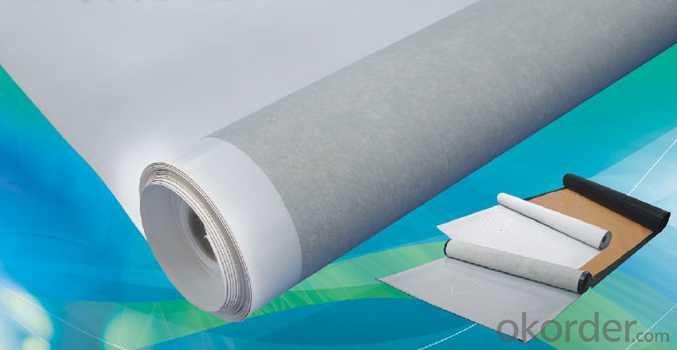

PVC Plastic Waterproof Membrane for Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of PVC Plastic Waterproof Membrane

High tension , perfect elongation ,perfect heating resistance .

Perfect jointing , It can be fused with base as a whole after heatingjointing .

High permeability ,chilling material and moisture can be expelled easily .

High aging resistance, UV resistance , corrosion resistance and erosion resistance .

Good cold flexibility (-20°C).

Service life can reach 50 years long with no pollution .

Surface can reflect UV .The temperature on the surface is low due to little absorbing heat.

Product features:

The physical and mechanical properties of stability, durability and anti ageing capacity is good, its oil and solvent resistance and general-purpose chloroprene rubber be roughly the same.

1 Good heat resistance, cold resistance, can be in (-60-150 C) within the scope of use.

2 Extension and rate very high tear strength, shrinkage cracking of buildings or a strong ability to adapt.

3 The proportion of light (0.90~0.97), the appearance of uniform quality, has good flexibility and elasticity.

4 Good weldability, materials can be directly welded, is conducive to ensure weld quality. After welding to form an integral waterproof layer.

5 Good dimensional stability, heat shrinkage is small, the deformation is small, keep a good state during construction.

6 Environmental protection type. Does not produce harmful substances in the production, construction and use of the process, and can be recycled, does not produce construction waste.

Specification of EPDM Waterproofing Membrane

1 | Breaking Tensile Strength(Room temperature) | Mpa | ≥7.5 | |

2 | Breaking Tensile Strength 60℃ | Mpa | ≥2.3 | |

3 | Breaking Elongation(Room temperature) | % | ≥450 | |

4 | Breaking Elongation(-20℃) | % | ≥200 | |

5 | Tearing strength | KN/m | ≥25 | |

6 | Impermeability, 30min no leakage | -- | 0.3Mpa no leakage | |

7 | Low temperature bending | ℃ | ≤ -40 | |

8 | Heating shrinking | Extension | mm | ≤2 |

Shrink | mm | ≤4 | ||

9 | Heat resistance (80℃x168h) | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥70 | ||

10 | Alkaline resistance, Ca(OH)2 solution, room temperature x168h | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥80 | ||

11 | Ozone aging(40℃x168h) | Elongation40%, 500x10-2 | -- | Non-crack |

12 | Synthetic aging | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥70 | ||

FAQ of EPDM Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Does a waterproofing membrane require any special tools or equipment for installation?

- Yes, the installation of a waterproofing membrane typically requires some special tools and equipment. These tools and equipment are necessary to ensure a proper and effective installation. Some common tools used during the installation process include a trowel, roller, brush, and squeegee. These tools help in applying the membrane evenly and smoothly. Additionally, specialized equipment such as a heat gun or torch may be required for certain types of waterproofing membranes that require heat activation. It is important to follow the manufacturer's instructions and guidelines when it comes to the tools and equipment needed for the specific type of waterproofing membrane being used. Using the correct tools and equipment will help ensure a successful installation and enhance the performance and longevity of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on cinder block surfaces?

- Yes, a waterproofing membrane can be used on cinder block surfaces. It provides an effective barrier against water penetration and helps to protect the cinder block from moisture-related damage.

- Q: Can a waterproofing membrane be used on tunnels with soundproofing systems?

- Tunnels with soundproofing systems can benefit from the use of a waterproofing membrane. It is common practice to integrate waterproofing membranes with soundproofing systems in tunnels. This is because tunnels are prone to water infiltration, which can cause structural damage and impact the performance of the soundproofing system. By applying a waterproofing membrane, the tunnel can be shielded from water intrusion, ensuring the durability and efficacy of the soundproofing system. Moreover, the waterproofing membrane aids in maintaining a dry and comfortable environment in the tunnel, which is essential for the efficient operation of the soundproofing system. Therefore, combining a waterproofing membrane with a soundproofing system is highly recommended in tunnels to provide both water protection and sound insulation.

- Q: Can waterproofing membranes be used on concrete pools?

- Yes, waterproofing membranes can be used on concrete pools. Waterproofing membranes are designed to provide a barrier against water penetration and can be applied to various surfaces, including concrete. Concrete pools are susceptible to water leakage over time due to cracks or deterioration, and applying a waterproofing membrane can help prevent these issues. The membrane is typically applied to the pool's interior surface, creating a seamless and watertight seal. It is important to choose a high-quality waterproofing membrane specifically designed for use in swimming pools to ensure long-lasting and effective results.

- Q: Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Yes, a waterproofing membrane can be used for shopping malls or commercial buildings. Waterproofing membranes are commonly used in construction to protect the structure from water damage. They are specifically designed to create a barrier against water infiltration, preventing leaks and moisture buildup. By applying a waterproofing membrane to the building's exterior, it helps to ensure the longevity and durability of the structure. Shopping malls and commercial buildings often have large surface areas that are exposed to different weather conditions, making them susceptible to water damage. Therefore, using a waterproofing membrane is an effective solution to protect these buildings and maintain their structural integrity.

- Q: Are there any specific building code requirements for using a waterproofing membrane?

- Yes, there are specific building code requirements for using a waterproofing membrane. Building codes vary by jurisdiction, but most require that waterproofing membranes meet certain standards and be installed in accordance with manufacturer instructions. These codes often specify the type of membrane that should be used, the minimum thickness, and the method of installation. For example, the International Building Code (IBC) mandates that waterproofing membranes be listed and labeled by an approved testing agency. The code also requires that the membrane be installed in a manner that provides continuous protection and is capable of withstanding anticipated structural movements and environmental conditions. In addition to the type and installation requirements, building codes may also dictate the testing and inspection procedures for waterproofing membranes. This ensures that the membrane is properly installed and will effectively prevent moisture intrusion, protecting the building from potential damage and deterioration. It is important to consult the local building code or work with a qualified professional to determine the specific requirements for using a waterproofing membrane in a particular jurisdiction. Compliance with these requirements is crucial to ensure a safe and durable waterproofing system that meets the necessary standards.

- Q: Is a waterproofing membrane resistant to punctures?

- Yes, a waterproofing membrane is generally designed to be resistant to punctures. It is engineered with durable materials and reinforced to provide protection against puncturing forces, ensuring its longevity and effectiveness in preventing water penetration.

- Q: How is a waterproofing membrane installed?

- Installing a waterproofing membrane typically involves a step-by-step process to ensure proper installation and effective waterproofing. Here is a general overview of how a waterproofing membrane is installed: 1. Surface Preparation: The first step is to prepare the surface where the membrane will be installed. This involves cleaning the surface thoroughly and removing any dirt, debris, or loose materials. It is essential to create a clean and smooth surface for optimal adhesion of the membrane. 2. Priming: Next, a primer is applied to the surface. The primer helps improve adhesion between the membrane and the substrate. It also provides a uniform surface for the membrane to adhere to. 3. Membrane Application: The waterproofing membrane is then applied to the prepared surface. There are different types of membranes available, such as sheet membranes or liquid-applied membranes. Sheet membranes are typically rolled out onto the surface and adhered using a suitable adhesive or self-adhesive backing. Liquid-applied membranes are spread or sprayed onto the surface in multiple coats, allowing each coat to cure before applying the next one. 4. Seam and Joint Treatment: In areas where multiple sheets or sections of the membrane meet, seams and joints are treated to ensure a watertight seal. This may involve overlapping the sheets and applying a seam tape or using a liquid-applied sealant to fill any gaps or joints. 5. Protection and Drainage: Once the membrane is installed, it is essential to protect it from damage and provide proper drainage. This can be achieved by installing a protective layer, such as a geotextile fabric or a drainage board, over the membrane. These layers help prevent punctures or abrasions and allow any water that penetrates the surface to drain away effectively. 6. Quality Control: After the installation is complete, it is crucial to perform quality control checks to ensure the membrane has been installed correctly. This may involve visual inspections, conducting water tests, or using specialized equipment to test the integrity of the membrane. It is important to note that the specific installation process may vary depending on the type of waterproofing membrane used and the requirements of the project. It is recommended to follow the manufacturer's guidelines and consult with a professional waterproofing contractor for accurate installation instructions.

- Q: Can a waterproofing membrane be used on stone surfaces?

- Yes, a waterproofing membrane can be used on stone surfaces. Waterproofing membranes are designed to protect various materials from water damage, including stone. They create a barrier that prevents water penetration, helping to preserve the integrity and longevity of the stone surface.

- Q: Can a waterproofing membrane be used for a water tank sealant?

- Yes, a waterproofing membrane can be used as a water tank sealant. Waterproofing membranes are designed to create a barrier against water penetration, making them an effective choice for sealing water tanks and preventing leaks.

Send your message to us

PVC Plastic Waterproof Membrane for Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords