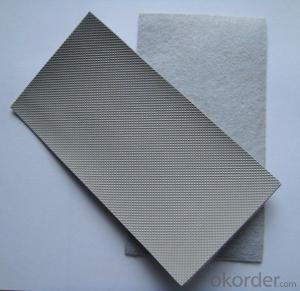

PVC Punched Waterproofing Membrane for Underground Leakage Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC membrane introduction:

Polyvinyl Chloride (PVC) membrane waterproof membrane is a kind of polymer compound

waterproof membrane compound of polyvinyl chloride colophony, plasticizer, stabilizing agent

,ultraviolet radiation(UV) resistance agent, all kinds of dyes and other agent.

1) Thickness: 0.3mm-2.0mm

2) Color: gray, green, blue

3.) Width: 2.0m

PVC waterproofing membrane is improved with the support of new technology,PVC waterproofing membrane, especially polyester reinforced pvc waterproofing membrane boasts the best quality in China at the moment.

Specification of PVC Waterproofing Membrane:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Remark: The property of artificial weathering might not be applicable to non-exposed product | |||

Characteristics of products:

Dimensionally stable

High mechanical strength

Vapour permeable

Highly flexible

Decay resistant

Root resistant

Weather and UV resistant

Hail resistant

High tensile strength

Application:

Reinforced PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes suitable for below-grade applications?

- Yes, waterproofing membranes are suitable for below-grade applications. Waterproofing membranes are specifically designed to prevent the infiltration of water into below-grade structures such as basements, foundations, and retaining walls. These membranes are made from durable materials that can withstand the pressure of soil and water, ensuring long-term protection against leaks and water damage. They are typically installed on the exterior side of the below-grade structure to create a barrier that prevents water from seeping through the walls or floors. Additionally, waterproofing membranes are flexible and can accommodate structural movements, ensuring their effectiveness even in challenging below-grade environments. Overall, waterproofing membranes are a reliable and effective solution for protecting below-grade structures from water intrusion.

- Q: Can a waterproofing membrane be used on insulation surfaces?

- Indeed, one can apply a waterproofing membrane to insulation surfaces. In fact, it is often advised to incorporate a waterproofing membrane above insulation as an extra layer of defense against water infiltration. This is particularly crucial in areas where moisture poses a concern, such as basements, roofs, or exterior walls. The waterproofing membrane functions as a barricade, preventing water from permeating the insulation and causing harm. It also aids in preserving the insulation's integrity and effectiveness by keeping it dry. Furthermore, certain waterproofing membranes have the added advantage of enhancing the insulation's energy efficiency by reducing air leakage and heat transfer. All in all, utilizing a waterproofing membrane on insulation surfaces is an intelligent and practical solution to safeguard your building or home from water damage.

- Q: Can waterproofing membranes be used on rooftop terraces?

- Yes, waterproofing membranes can be used on rooftop terraces to protect them from water damage and ensure their longevity.

- Q: Can a waterproofing membrane be used in rooftop gardens or green roofs?

- Yes, a waterproofing membrane can be used in rooftop gardens or green roofs. It is an essential component to prevent water leakage and protect the underlying structure from moisture damage. The membrane acts as a barrier, preventing water from penetrating the roof and causing potential structural issues. This ensures that the rooftop garden or green roof remains well-maintained and functional.

- Q: Can waterproofing membranes be used on concrete block walls?

- Yes, waterproofing membranes can be used on concrete block walls. These membranes are specifically designed to prevent water penetration and can effectively protect concrete block walls from moisture damage.

- Q: How does a waterproofing membrane handle settlement or movement of the substrate?

- A waterproofing membrane is specifically designed to handle settlement or movement of the substrate. It achieves this by offering flexibility and elasticity. Typically, it is made from materials such as modified bitumen, polyurethane, or acrylic polymers. These materials possess the ability to stretch and contract without compromising the membrane's integrity. In the event of settlement or movement in the substrate, the waterproofing membrane adjusts its shape and size accordingly. This prevents the occurrence of cracking or tearing in the membrane, which could result in water infiltration and damage to the underlying structure. Some waterproofing membranes go even further by including reinforcing layers or fabrics embedded within them. These layers enhance the membrane's strength and resistance to movement. They also help distribute stress and forces caused by settlement or movement, providing further protection against potential damage. In addition, proper installation techniques are of utmost importance to ensure the waterproofing membrane can effectively handle settlement or movement. The membrane should be applied in a continuous and seamless manner, using appropriate adhesives or fasteners to secure it to the substrate. This ensures that the membrane can flex and move in sync with the substrate, rather than resisting or restricting its movements. To sum up, a waterproofing membrane is created to accommodate settlement or movement in the substrate. It achieves this through flexibility, elasticity, and reinforcement. Proper installation techniques are crucial to ensure its effectiveness in handling these movements and maintaining a watertight barrier.

- Q: Can a waterproofing membrane be used in agricultural structures?

- Yes, a waterproofing membrane can be used in agricultural structures. It can help protect the structure from water damage, prevent moisture-related issues, and ensure a longer lifespan for the agricultural building.

- Q: Can a waterproofing membrane be used for pond or pool applications?

- Certainly! A waterproofing membrane is suitable for both pond and pool applications. Its main purpose is to create a barrier that prevents water from penetrating, making it an excellent choice for sealing ponds and pools. These membranes are typically made from synthetic materials like PVC, EPDM, or TPO, all of which have high resistance to water and UV rays. They come in different thicknesses and can be tailored to fit the specific dimensions of the pond or pool. Moreover, waterproofing membranes are incredibly durable and flexible, allowing them to withstand continuous exposure to water and the movement of the underlying substrate. In summary, utilizing a waterproofing membrane for pond or pool applications helps avoid leaks, extends the lifespan of the structure, and guarantees a safe and enjoyable water environment.

- Q: Can a waterproofing membrane be used for a fountain waterproofing system?

- Yes, a waterproofing membrane can be used for a fountain waterproofing system. A waterproofing membrane is a barrier that is designed to prevent water from infiltrating or leaking through the structure it is applied to. This membrane is typically made of materials such as rubber, PVC, or bitumen, and is applied to surfaces such as concrete, stone, or masonry. In the case of a fountain waterproofing system, a waterproofing membrane can be applied to the interior surfaces of the fountain to prevent water from seeping through and causing damage. The membrane acts as a protective layer that ensures the water remains contained within the fountain, preventing leaks or seepage. It is important to select a waterproofing membrane that is specifically designed for fountains or water features. This type of membrane should be able to withstand constant exposure to water, as well as the specific conditions and chemicals that may be present in a fountain environment. Additionally, proper installation and maintenance are crucial to ensure the effectiveness of the waterproofing membrane. It is recommended to consult with a professional waterproofing contractor or fountain specialist to assess the specific requirements of your fountain and to determine the most suitable membrane and installation method. Overall, a waterproofing membrane can be an effective solution for ensuring the waterproofing of a fountain system, helping to maintain its structural integrity and prevent water-related damage.

- Q: Can waterproofing membranes be used on concrete block walls?

- Yes, waterproofing membranes can be used on concrete block walls. In fact, it is often recommended to use waterproofing membranes on concrete block walls to prevent water infiltration and moisture damage. Waterproofing membranes are designed to create a barrier against water and can be applied to the exterior or interior surface of the concrete block walls. These membranes provide an additional layer of protection, preventing moisture from seeping into the walls and causing issues such as mold growth, efflorescence, and deterioration of the concrete blocks. By using waterproofing membranes, you can ensure the longevity and durability of your concrete block walls.

Send your message to us

PVC Punched Waterproofing Membrane for Underground Leakage Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords