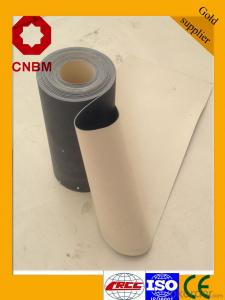

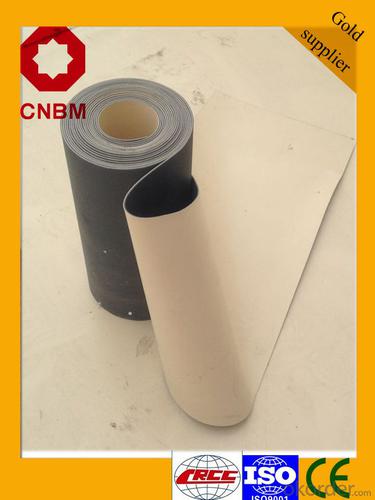

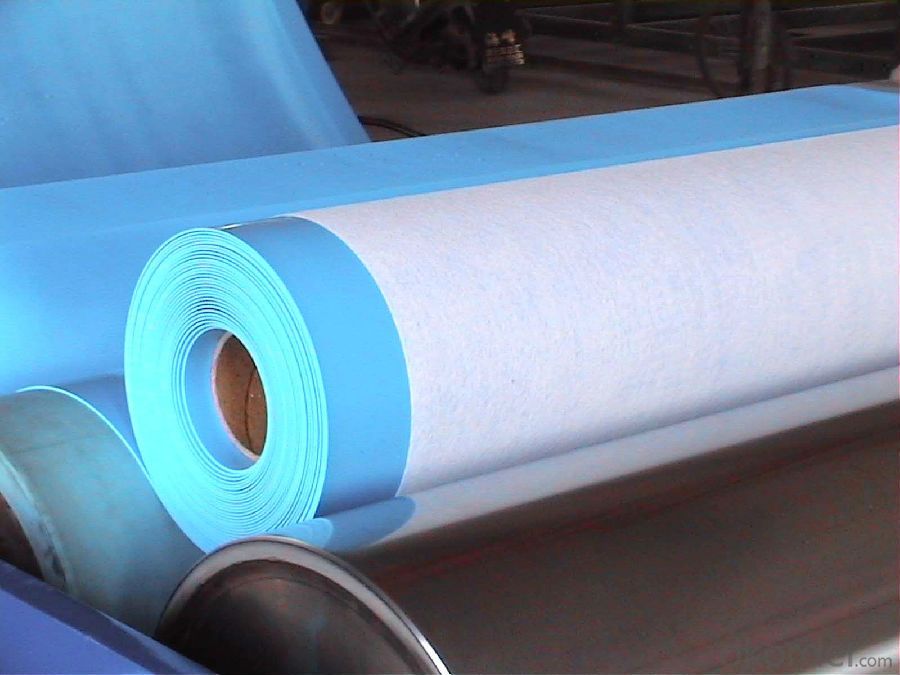

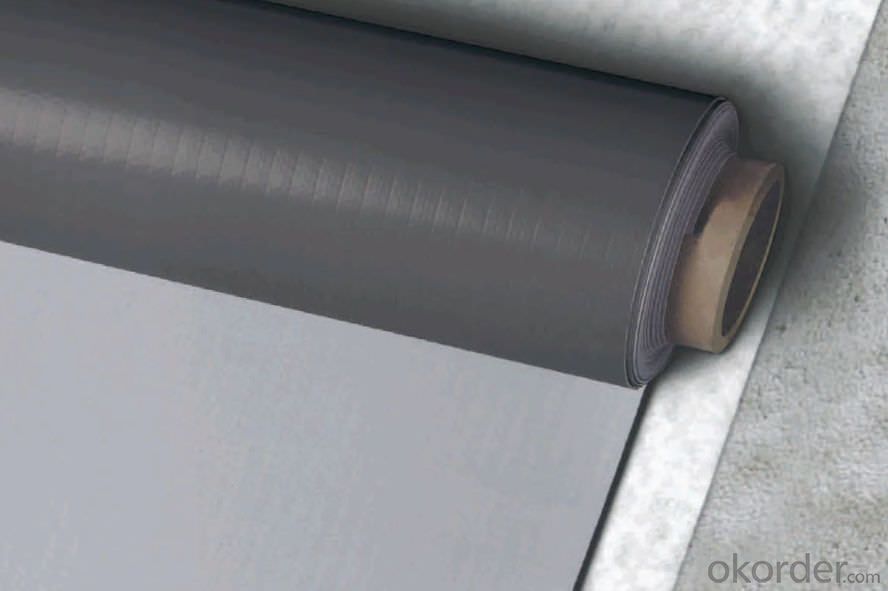

PVC Waterproof Rolling Membranes With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The P series waterproofing membrane is a heatweldable membrane produced with an integral polyester reinforcement for high strength,for use in a Magical Stone's solution system. Its excellent performance of resistance to plasticizer extraction and migration, extend the product's life and more friendly to environment.

Application Scope

Waterproofing, anti-seepage and moisture proof of side walls of basements, baseboards, head plates and roofs.

Advantagee

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

9.High Strength

10. Hot-air welded seams for long-term performance

11.Proven membrane performance

12. Excellent resistance to plasticizer extraction and migration performance.

Composition:

The P series waterproofing membrane is a high-quality,thermoplastic PVC membrane with a polyester scrim reinforcement. We solved the problem of extraction and migration of PVC plasticizer in production, make the products the best durability in thermoplastic waterproofing.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used in conjunction with concrete repair or restoration?

- Indeed, it is common practice to utilize a waterproofing membrane in conjunction with concrete repair or restoration. It is advisable to employ a waterproofing membrane as a safeguarding layer on top of repaired or restored concrete surfaces. This is due to the potential compromise of the original concrete's waterproofing properties during the repair or restoration process. Application of a waterproofing membrane guarantees the continued protection of the repaired or restored concrete against water infiltration, thereby preventing additional harm and deterioration. Moreover, the waterproofing membrane contributes to bolstering the overall strength and lifespan of the concrete structure.

- Q: Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Yes, a waterproofing membrane can be used for shopping malls or commercial buildings. Waterproofing membranes are commonly used in construction to protect the structure from water damage. They are specifically designed to create a barrier against water infiltration, preventing leaks and moisture buildup. By applying a waterproofing membrane to the building's exterior, it helps to ensure the longevity and durability of the structure. Shopping malls and commercial buildings often have large surface areas that are exposed to different weather conditions, making them susceptible to water damage. Therefore, using a waterproofing membrane is an effective solution to protect these buildings and maintain their structural integrity.

- Q: How do waterproofing membranes prevent water leakage?

- Waterproofing membranes prevent water leakage by creating a physical barrier between the structure and the water. These membranes are made of materials that are impermeable to water, such as rubber, PVC, or bitumen. When applied correctly, they form a continuous and seamless layer that prevents water from seeping through cracks, joints, or other vulnerable areas. This barrier effectively stops water from infiltrating the structure, ensuring its protection against water damage and leakage.

- Q: Can a waterproofing membrane be used for walkways or pedestrian bridges?

- Yes, a waterproofing membrane can be used for walkways or pedestrian bridges. Waterproofing membranes are designed to create a barrier that prevents water from seeping into the structure and causing damage. By applying a waterproofing membrane to the surface of a walkway or pedestrian bridge, it can protect the underlying structure from water infiltration, thus increasing its durability and lifespan. This is especially important in areas prone to heavy rainfall or where the walkway or bridge is exposed to water sources such as rivers or lakes. Additionally, waterproofing membranes can also provide additional benefits such as improving slip resistance and protecting against chemicals or pollutants.

- Q: Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

- Q: Can a waterproofing membrane be used on balconies or decks?

- Balconies or decks can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to offer a shield against water and moisture, making them an ideal solution for outdoor spaces that are constantly exposed to the elements. Their composition typically includes rubber, PVC, or bitumen, and they are directly applied to the surface of the balcony or deck. By doing so, they effectively prevent water from penetrating the underlying structure, safeguarding it against potential damage caused by moisture. Waterproofing membranes prove particularly advantageous in areas prone to heavy rainfall, snow, or high humidity, as they effectively prolong the lifespan of the balcony or deck by preventing water-related issues such as rot, mold, or deterioration. Moreover, these membranes also serve as an additional layer of protection against harmful UV rays, effectively preventing discoloration or fading of the balcony or deck surface. Ultimately, opting for a waterproofing membrane for balconies or decks is a wise investment that ensures their durability while maintaining their aesthetic appeal.

- Q: Can a waterproofing membrane be used on both horizontal and vertical surfaces of a structure?

- Both horizontal and vertical surfaces of a structure can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier against moisture and are commonly utilized in various applications including roofs, basements, foundations, balconies, and walls. Due to their flexibility, they can easily adapt to different surface orientations, making them suitable for both horizontal and vertical installations. The flexibility of the membrane enables it to be applied and adhere effortlessly to different surfaces, effectively protecting against water infiltration and potential damage caused by moisture. Whether it is used on a roof or a wall, a waterproofing membrane is capable of preserving the integrity and longevity of a structure by preventing water penetration and potential water-related issues.

- Q: Are waterproofing membranes resistant to hydrostatic pressure?

- Yes, waterproofing membranes are designed to be resistant to hydrostatic pressure.

- Q: Can a waterproofing membrane be used for residential swimming pools?

- Yes, a waterproofing membrane can be used for residential swimming pools. These membranes are specifically designed to provide a water-resistant barrier, preventing leakage and protecting the structure of the pool. Waterproofing membranes are commonly used in various applications, including swimming pools, to ensure durability and longevity of the pool.

- Q: Are waterproofing membranes resistant to alkalis?

- Yes, waterproofing membranes are generally resistant to alkalis.

Send your message to us

PVC Waterproof Rolling Membranes With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords