PVC PU Conveyor Belt in Food Industry White Food Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC PU Conveyor Belt in Food Industry White Food Belt

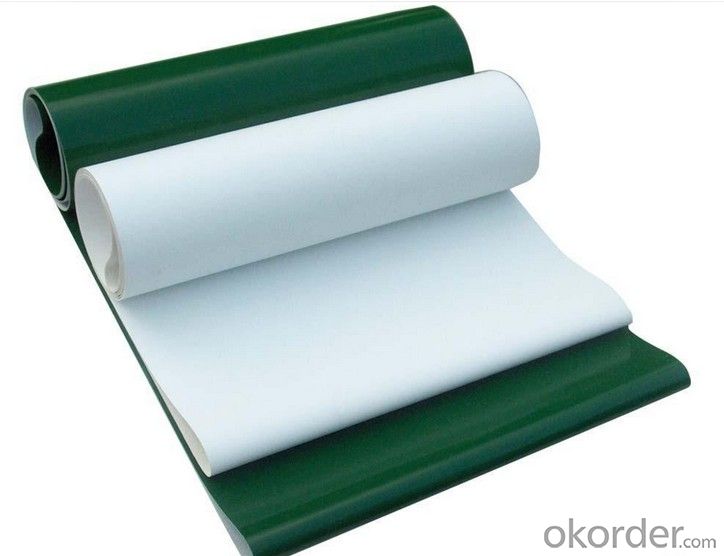

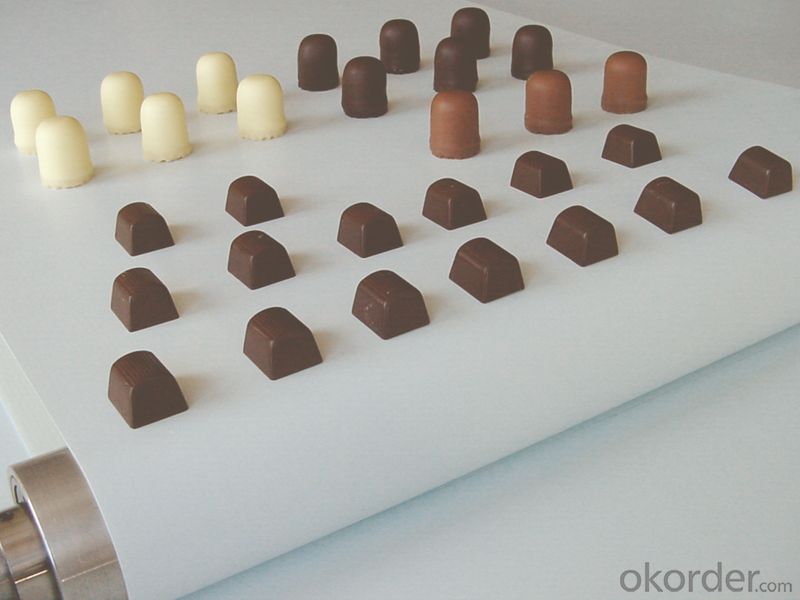

Description of PVC / PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

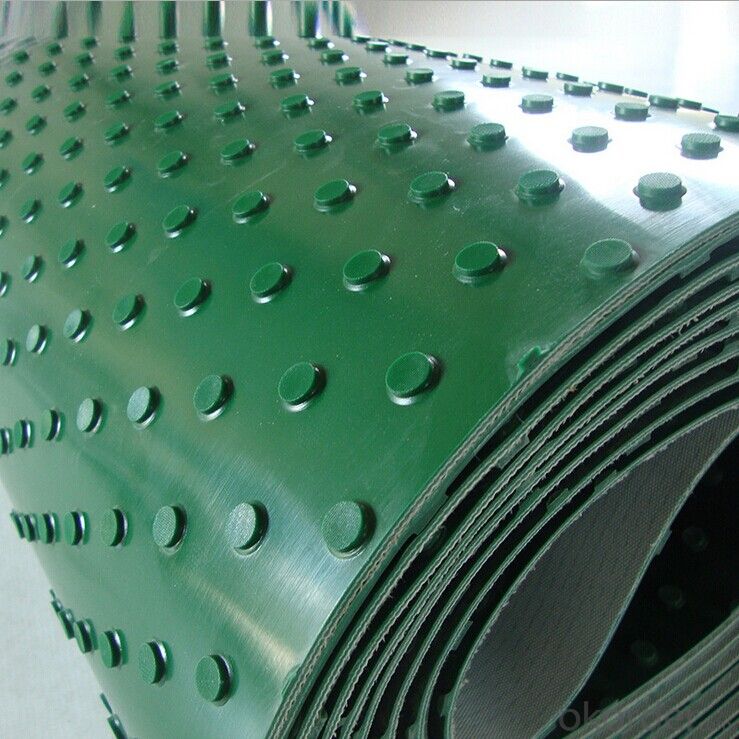

The main products include flat surface series, anti-slid series which diversified in a lot of textures for meeting different conveying conditions and environment, featuring anti-static, anti-corrosion, flame retardant etc.

There are wide range of patterns of rough top belt available including Diamond, Chevron, Herringbone, Rib, Grid, Wave, Round and Oval nubs, Convex-tooth etc.

Advantages of PVC/PU Conveyor Belt

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Applications of PVC/PU conveyor belt

Widely used in the Conveyance and production assembly lines in the areas of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre , electronics, pharmaceutical, printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How should the rubber products be dirty?

- First coated with vinegar on the top, after dry, and then wipe paper, so clean

- Q: Does antirust oil affect rubber?

- Antirust oil on rubber must have some influence, and a variety of anti rust oil, you can choose corrosive minimum rust preventive oil,,

- Q: How does rubber mobile phone cover change yellow?

- Generally discarded, disposed of, replaced by new ones.Can be used to deal with non toothpaste brush view can restore the original color!

- Q: Will the rubber ring of the thermos bottle be harmful to the human body?

- No harmThe rubber washer of the thermos bottle comprises a common thermos bottle, an air pressure thermos bottle, an electric pressure bottle and an automatic electrothermal thermos bottle, etc. the rubber sealing washer is directly contacted with the drinking water, and is sealed and heat insulated

- Q: How are rubber wires processed?

- In the production of rubber products, vulcanization is the last process.Vulcanization is a crosslinking process in which rubber molecules change from linear structure to network structure under certain conditions. Curing methods are cold vulcanization, room temperature vulcanization and heat vulcanizing three kinds. Most rubber products are vulcanized by heat. Hot vulcanizing equipment, vulcanizing pot, flat vulcanizing machine, etc.. Rubber wires and cables are vulcanized by continuous hot air.

- Q: How are rubber wires processed?

- [summary] the main raw material is rubber, rubber products with various agents, as well as the fiber and metal skeleton material, the basic production process of rubber products including plastication, mixing, calendering, extrusion, molding, curing 6 basic processes.The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q: What is the size of the scorch time of the rubber?

- Scorch time, or T10, is the time required for torque to reach 10%. Scorch is the phenomenon of early vulcanization occurring in the processing of rubber compound.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- Tensile strength is the ultimate ability to characterize a product against tensile failure.

- Q: What is a rubber accelerator? What role?

- Thiofide ETU (Na-22), Thiofide DETU, Thiofide ZDC (EZ), Thiofide ZDMC (PZ) Thiofide ZDBC (BZ), Thiofide ZMBT (MZ), Thiofide TMTM, Thiofide MBT (M), Thiofide MBTS (DM)

- Q: Is rubber flame retardant?

- Mainly to see the use of related products, for example, the glass door rubber strip is flame retardant, and the vehicle's internal and external tires are not flame retardant.

Send your message to us

PVC PU Conveyor Belt in Food Industry White Food Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords