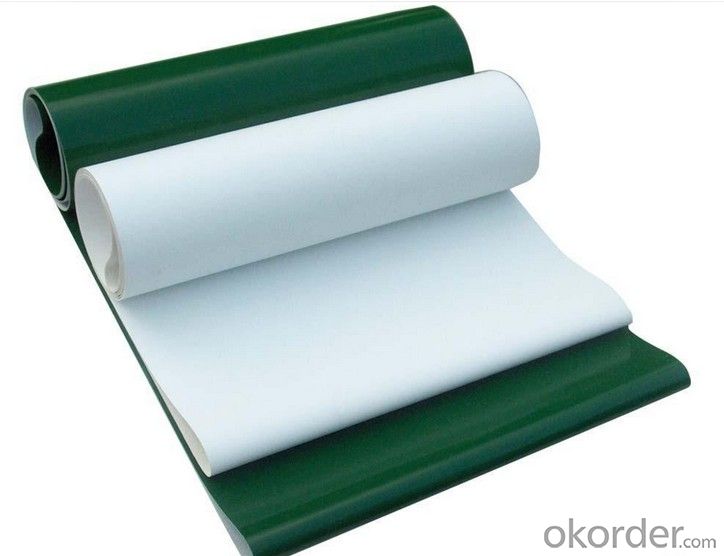

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

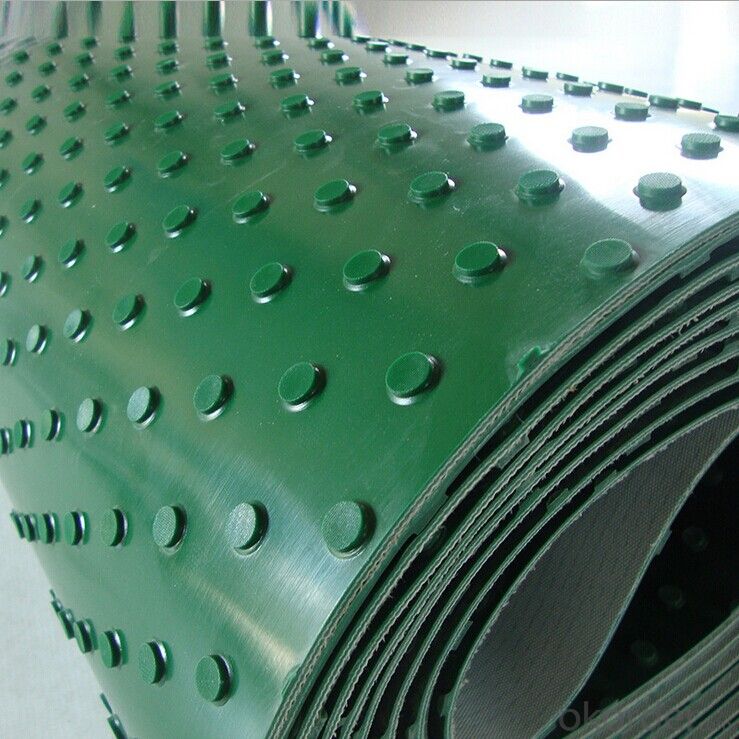

Descriptions of PVC Conveyor Belt

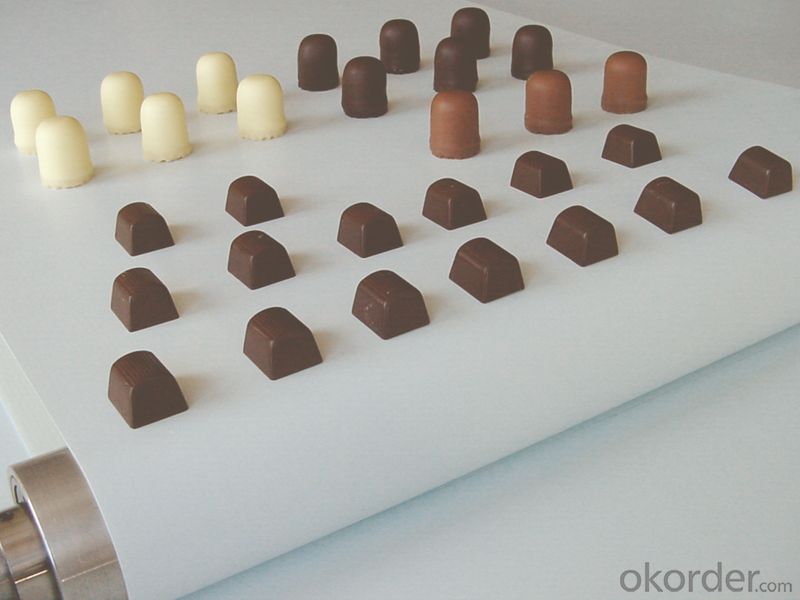

PVC conveyor belt for Conveyance and production assembly lines in the areas of food,beverage, cigarettes,tobacco,airportetc.

Thickness: 2.0mm

Width: Width of the largest production 3 meter

Length: According to the customer request production. Regular length is 100 meters.

Color: White, green, black etc.

Can be produced as customers' requirements, such as thickness, width and length.

Features of PVC Conveyor Belt

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

It adopts high-intensity polyester filament and yarn weave as the whole core, and then is impregnated by the PVC&PU. We introduce the key technologies and equipment from the United Kingdom Specialization (Fenner) Corporation in the production.

Applications of PVC conveyor belt

Widely used in the Conveyance and production assembly lines in the areas of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre , electronics, pharmaceutical, printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How should the rubber products be dirty?

- First coated with vinegar on the top, after dry, and then wipe paper, so clean

- Q: How long is the warranty period for EPDM?

- Rubber product (rubber products) refers to the natural and synthetic rubber as raw material to produce all kinds of rubber products activities, including the use of waste rubber reproduction of rubber products.

- Q: Is sandal rubber bottom good or polyurethane good?

- Overall, the bottom and bottom of polyurethane rubber polyurethane rubber bottom bottom than everyone has his hobby, more wear and more folding, but lighter than polyurethane rubber bottom bottom.

- Q: How does rubber mobile phone cover change yellow?

- In physical properties, rubber has swelling, rheological properties and other changes. Tensile strength, elongation at break, impact strength, flexural strength, compression ratio and elasticity decrease.

- Q: Rubber Mooney value is what meaning, what is the role of

- Mooney viscosity (Mooney viscosity) also called rotation (Mooney) is determined by numerical viscosity, Mooney viscometer, synthetic rubber can basically reflect the degree of polymerization and molecular weight. The rotor is a standard Mooney viscometer, at a constant speed (2 RPM), rotating in a closed chamber in the sample the viscosity change of shear resistance. The size of the sample and the rotation of the rotor during the curing process, through the force measuring device is displayed on the dial to Mooney units, at the same time interval can be read Mooney, vulcanization curve, door number rose after the first drop, 5 unit increase in the time from the lowest point called the Mooney scorch time, the Mooney scorch and then increased to 30 units and the time that scorch time.

- Q: How do rubber undergo vulcanization?

- Rubber vulcanization is a chemical reaction process, before vulcanization rubber is present in a linear molecular form, is the linear sulfide molecules through some other substances (such as sulfur and peroxide) connected together to form a three-dimensional network structure. Sulfur must not be used with sulfur material, as long as the rubber linear molecules can be linked together to form a body shape on the lineEach rubber formulation has an optimum curing temperature, which increases the speed of vulcanization within a certain range, but the performance of the product decreases

- Q: Is vulcanized sole good or rubber sole is good?

- Rubber sole refers to some students glue, wear resistance, good elasticity, also known as Dichotomanthes bottomIn general, there are advantages to each other, depending on what kind of thing you like

- Q: What are the forming methods of rubber products?

- In these methods, injection molding has the significant advantages of simplifying process, reducing the number of operators; second, reduce the energy consumption of about 10%; the production efficiency is improved by 4 ~ 7 times; improve product uniformity, stability, size precision and the qualification rate; reduce the flash, saving material and convenient operation;, low labor intensity, high degree of mechanization and automation. Therefore, in recent years, more and more attention has been paid to injection molding technology, and it has been developed rapidly in rubber products production

- Q: How to improve the aging resistance of rubber?

- In the course of oxidation, ozone can produce molecular cracks, but also make the deformed rubber crack in the direction of stress, namely ozone cracking".Heat will increase the temperature, thermal cracking or thermal crosslinking of rubber will accelerate the oxidation rate of the rubber, that is, heat aging.

- Q: How can rubber products be softened?

- Softener generally need to add a certain amount of plasticizer in rubber processing. It is usually of low softness to make the rubber softMolecular substances, they can increase the plasticity of rubber, liquidity, adhesion, in order to facilitate molding and molding and other process operations. It can also help the powder mixture to disperse and reduce the mixing temperature, at the same time, it can reduce the viscous flow temperature and the glass transition temperature of rubber, and improve the low temperature resistance of rubber.

Send your message to us

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords