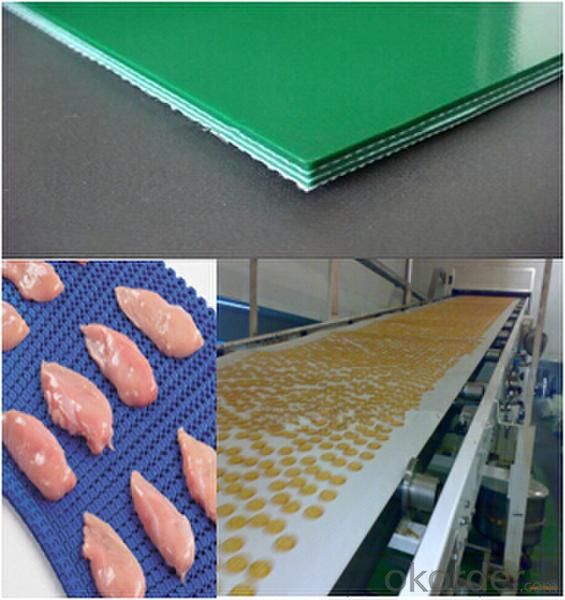

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

Specifications:

The PVC conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant. Our food conveyor belts are FDA/USDA approved and most types also have USDA Dairy Approvedand support your HACCP concept.

Features:

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

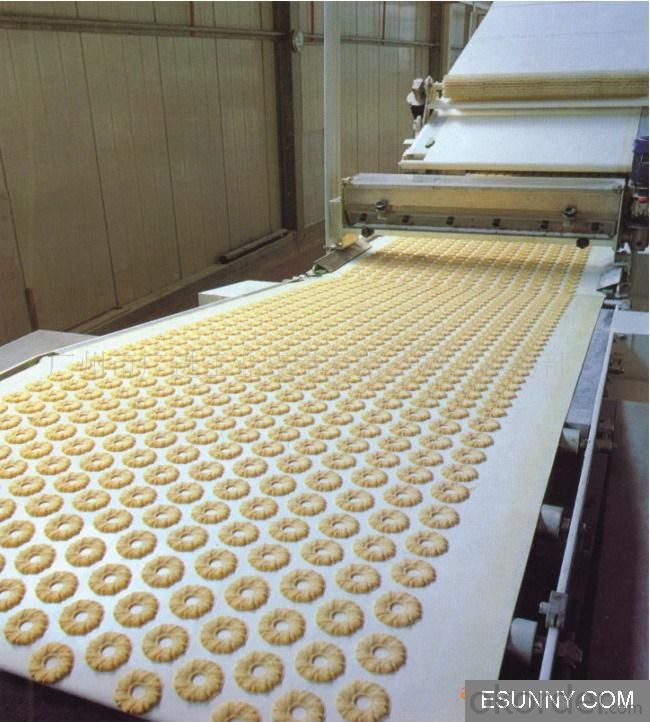

Application:

The belts are bets suited for varied applications like light weight conveyors systems, such as food processing industry, tobacco industry, textial, marble, wood, etc.

We can product various kinds of conveyor, and we also can customize with your requirement

PVC Solid Woven Conveyor Belt:

Ø Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Ø Cover thickness can be from 0.5 to 4mm.

Ø Nitrile covered PVG type

Ø Suitable for applications at a slope angle of less than 20 degrees, thickness can be 1 to 18mm.

Ø Resistance to wetness, slip, low temperature and wear resistance of the belt.

| Specification | Thickness (mm) | Color | Style |

| 1 ply fabric~1 ply p | 1 | green/white | plain |

| 1 ply fabric~2 ply p | 2/3/4/5 | green/white | skirt lace |

| 2 ply fabric~2 ply p | 2/3 | white/B.matt/green | diamond with small dot/grass |

| 2 ply fabric~3 ply p | 3 | green | diamond |

| 3 ply fabric~3 ply p | 4/5/6/7 | white/green matt | network wire |

| 3 ply fabric~4 ply p | 4/5 | green | diamond |

| 4 ply fabric~4 ply p | 9 | green matt | marble |

Above the form just list a part, we can product as your requirement, welcome to negotiate.

- Q: What is the difference between a thermoforming machine and an injection molding machine in a rubber plant?

- Hot pressing machine needs a forming template to process it, so there are many processes.If you shoot it, you can finish the product directly

- Q: Why is rubber forest a green desert?

- The "green desert" refers to a large area of green trees, the tree species is single, consistent with age and height, and very dense. The dense single canopy layer completely blocked the sunlight, resulting in the growth of lower vegetation and lack of intermediate shrub and ground vegetation in the understory.

- Q: What kind of rubber products are expensive?

- Other technologies, processes, and logistics all determine the cost

- Q: How to distinguish between good and bad silicone rubber gasket?

- When the silica gel products are subjected to alternating stress (or strain), the structure and properties of the material change. With the development of fatigue process, the failure of silica gel products is called fatigue damage. Therefore, fatigue is also a way to distinguish the quality of silicone products.

- Q: Doors and windows shock absorber seals, rubber blocks, rubber products, do not know where to buy, where suppliers?

- A customer feels that the product is cheaper, and there is a problem with the quality. Products are free to send samples, but also the implementation of standards, quality inspection reports, technical data and other samples along with the courier in the past, so that in exchange for each other's trust, and has become a long-term partner.

- Q: How long does the rubber last?

- In addition, aging has ozone aging, weather aging, heat aging and so on. Ding Qing rubber is not resistant to ozone, the time is not long, it will appear aging.

- Q: Rubber products are not allowed to touch oil products, but why can rubber gloves be contacted daily? What's the point?

- Contact every day is not every day inside the bubble, the contact time is short, the impact on rubber is very small.Raw rubber rubber products are: natural rubber, isoprene rubber, nitrile rubber, EPDM rubber, polybutadiene rubber, styrene butadiene rubber, polyurethane rubber, chloroprene rubber, silica gel etc.

- Q: EPDM rubber foam?

- Its characteristics: due to the internal foaming material containing a large amount of air or other gas, and should not be in circulation, especially the closed cell foam, with independent foam completely separated, material can obviously slow down on the heat conduction coefficient of heat conduction, very basic, more softness of the material itself, and good elasticity, can be used as the car, insulation materials, household appliances, ship electronic equipment, medical equipment, fitness equipment, such as the ideal air conditioning pipeline...

- Q: What is the rubber composition of sole?

- The sole of high pressure polyethylene and rubber flavor, rubber and plastic used together.Student: Rubber soled heavy, expensive, not resistant to oil, heat. Variable color.

- Q: How is the temperature range of rubber determined?

- Vulcanized rubber is related to vulcanizing reagents, fillers and so on! The low temperature limit generally refers to the glass transition temperature. Of course, the finished rubber also has the physical properties required by the customer for the low temperature dynamic work!

Send your message to us

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords