White Food Grade PU Conveyor Belt PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Food Grade PU Conveyor Belt PVC Conveyor Belt

Conveyor Belt Descriptions

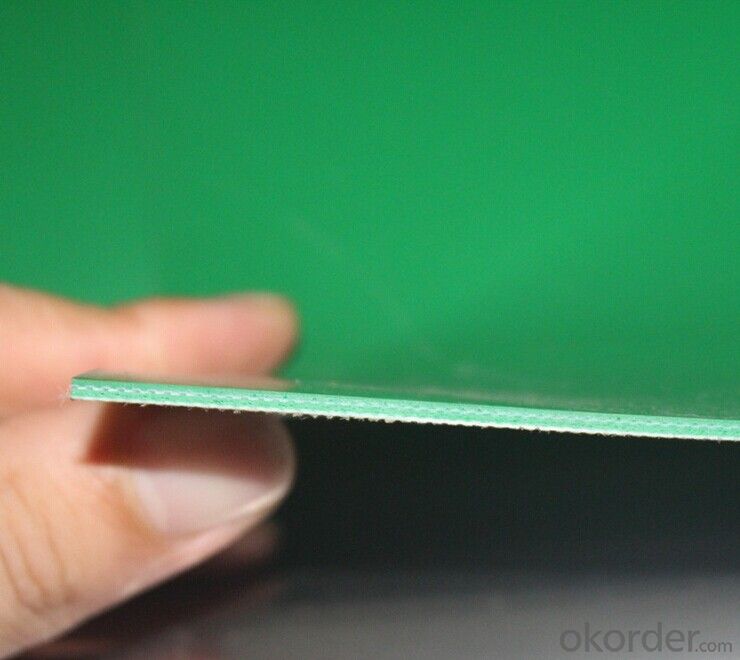

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

Conveyor Belt Specifications

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Conveyor Belt Working environment

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

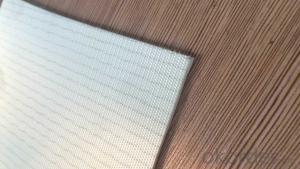

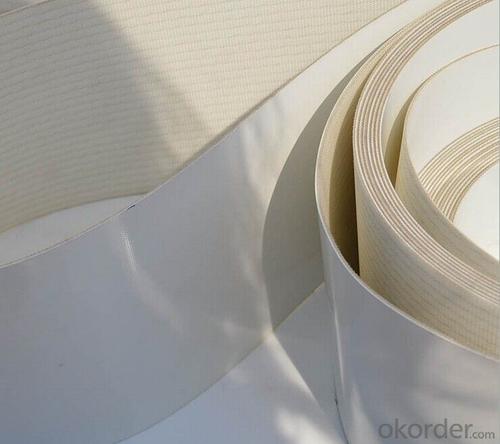

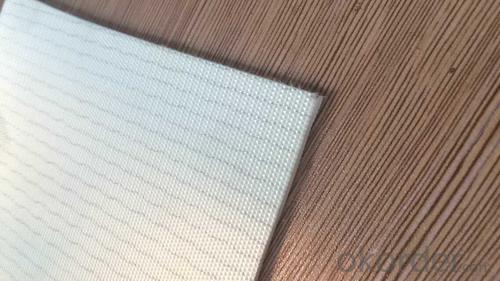

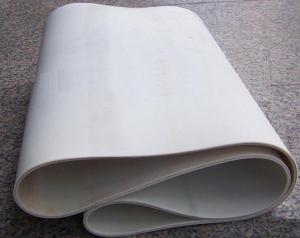

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How can I remove the scratches on the plastic?

- The so-called plastic, in fact, it is a kind of synthetic resin, the shape of the natural resin with pine resin similar to, through chemical means of artificial synthesis, and is called plastic.

- Q: Can olive nets be used for olive trees in windy regions?

- Yes, olive nets can be used for olive trees in windy regions. Olive nets are designed to protect the olives from birds and other pests, but they can also provide some protection against wind damage. However, in extremely windy regions, additional measures may need to be taken to ensure the stability of the olive nets and prevent them from getting damaged.

- Q: Can olive nets be used in hilly or sloped orchards?

- Yes, olive nets can be used in hilly or sloped orchards. The nets can be installed on terraces or slopes to protect the olives from falling off the trees and to facilitate harvesting.

- Q: How do you prevent olive nets from causing injuries to workers during harvesting?

- To prevent olive nets from causing injuries to workers during harvesting, several measures can be implemented. Firstly, training sessions should be conducted to educate workers about the potential risks associated with working around olive nets and the proper techniques to handle them safely. Additionally, workers should be provided with personal protective equipment (PPE) such as gloves, helmets, and sturdy footwear to minimize the risk of injuries. Regular inspection and maintenance of the nets is crucial to identify any damages or weak spots that could pose a safety hazard. Clear communication and teamwork are essential during harvesting to ensure that workers are aware of each other's positions and actions, reducing the chances of accidents. Supervisors should closely monitor the work environment and promptly address any safety concerns that arise. Lastly, implementing engineering controls like installing barriers or guardrails around the areas where nets are used can further enhance worker safety by providing physical protection against potential falls or entanglement. By combining proper training, PPE, regular maintenance, effective communication, and engineering controls, the risk of injuries caused by olive nets during harvesting can be significantly reduced.

- Q: How do olive nets prevent olives from falling to the ground?

- Olive nets are placed under olive trees to catch the olives as they naturally fall off. The nets act as a barrier, preventing the olives from hitting the ground and getting damaged or lost.

- Q: How do I store olive nets when not in use?

- To store olive nets when not in use, it is best to clean them thoroughly to remove any dirt or debris. Afterward, allow them to dry completely to prevent mold or mildew growth. Then, neatly fold or roll the nets and store them in a cool, dry place, preferably in a sealed container or bag to protect them from dust or pests.

- Q: How do olive nets prevent insect damage to olives?

- Olive nets prevent insect damage to olives by creating a physical barrier that blocks insects from reaching the trees and fruits. The nets are typically placed over the olive trees, acting as a protective shield against pests. This prevents insects from laying eggs, feeding on the olives, or transmitting diseases to the fruit. Additionally, olive nets also help reduce the risk of birds and other animals causing damage to the olives.

- Q: Can olive nets be used in regions with extreme temperature variations?

- Yes, olive nets can be used in regions with extreme temperature variations. Olive nets are primarily used to protect olive trees from birds and other pests, and they are not affected by temperature variations. However, the durability and longevity of the nets may be influenced by extreme temperatures, so it is important to choose high-quality nets that are specifically designed to withstand such conditions.

- Q: Do olive nets come with any warranties?

- Yes, olive nets typically come with warranties that vary depending on the manufacturer or seller. It is recommended to check with the specific brand or retailer to determine the details and terms of the warranty coverage.

- Q: Can olive nets be used in olive groves with limited access to roads?

- Yes, olive nets can be used in olive groves with limited access to roads. Olive nets are lightweight and portable, making them suitable for such groves. They can be easily transported to the grove by alternative means, such as smaller vehicles or even by hand.

Send your message to us

White Food Grade PU Conveyor Belt PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords