China Manufacturer PVC Food Conveyor Belt,OEM,Food Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

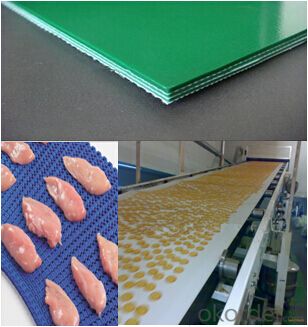

China Manufacturer PVC Food Conveyor Belt,OEM,Food Standard

Description of PVC Conveyor Belt:

1. Anti-fire, anti-static

2. Certificate:ISO9002

3. Factory with short delivery time

4.high intensity fabric

Characteristics of PVC Conveyor Belt:

It adopt high-intensity polyester filament and yarn weave as the whole core, and then is impregnated by the PVC. We introduce the key technologies and equipment from the United Kingdom Specialization (Fenner) Corporation in the production.

Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Cover thickness can be from 0.5 to 4 mm.

Standard Ranges

We have more than 100 types of belt and a wide range of belt accessories.

Features of PVC Conveyor Belt

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

Various surfaces with high, medium, and low coefficient friction

Dimensional stability

Less noise

Special belts can also be manufactured complete with

1) Guides, profiles and sidewalls fitted by means of high frequency or hot air welding machines.

2)Curved or Corner conveyor belts it allows the solving of logistic problems through the deviation of the conveying system from a few degrees to a 180°C turn.

3)Belts can be made endless, spliced or with prepared ends for on-site splicing to be done with dedicated Adhesives.

Applications of PVC Conveyor Belt:

Airports

Postal automation

Parcel handling

Treadmills

Packaging and wrapping

Confectionery Industry

Food Processing Industry

Paper Printing Industrys

Photo of PVC Conveyor Belt:

If you want to find more details about the pvc food conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What are the hazards of rubber accelerators?

- I have been engaged in the rubber industry for many years. I personally think that the accelerator has no harm to people. Wearing gloves, masks and protective measures during operation will not be harmful.

- Q: How long is the warranty period for EPDM?

- Rubber product (rubber products) refers to the natural and synthetic rubber as raw material to produce all kinds of rubber products activities, including the use of waste rubber reproduction of rubber products.

- Q: Excuse me, is PU one kind of silicone? Or what is the connection between the two?

- PU is the abbreviation of Polyurethane, Chinese name is polyurethane, referred to as polyurethane. Because of the simple modification of the formula, different density, elasticity, rigidity and other physical properties can be obtained. At present, a large number of glass fiber insulation materials, wood, traditional rubber products and so on.

- Q: Why do rubber products Blister?

- As the temperature is too high, the rubber organic matter boiling point is low, and then because of pressure, it will increase the internal energy, leading to temperature rise.As long as the temperature is lowered and the pressure is right, you can try not to blister

- Q: Does it work in a rubber factory that causes skin irritations?

- Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: Doors and windows shock absorber seals, rubber blocks, rubber products, do not know where to buy, where suppliers?

- A customer feels that the product is cheaper, and there is a problem with the quality. Products are free to send samples, but also the implementation of standards, quality inspection reports, technical data and other samples along with the courier in the past, so that in exchange for each other's trust, and has become a long-term partner.

- Q: What is rubber leather?

- The general rubber has good comprehensive properties and is widely used. The main contents are as follows: natural rubber. From the latex of the Hevea tree, the basic chemical composition is cis polyisoprene. Good elasticity, high strength and good comprehensive performance. Isoprene rubber. The full name is cis -1, 4- polyisoprene rubber, a high CIS synthetic rubber made from isoprene, because of its structure and properties similar to natural rubber, it is also called synthetic natural rubber. Styrene butadiene rubber. Referred to as SBR, made by copolymerization of butadiene and styrene. According to the production method, emulsion polymerization, styrene butadiene rubber and solution polymerized styrene butadiene rubber are divided into emulsion polymerization. Its comprehensive properties and chemical stability are good. The br. The full name is cis -1, 4- polybutadiene rubber, referred to as BR, made from butadiene polymerization. And the other than universal rubber, vulcanized butadiene rubber cold resistance, abrasion resistance and excellent elasticity, dynamic load, less heat, good aging resistance, easy and natural rubber, chloroprene rubber, nitrile rubber and etc..

- Q: What is rubber made of?

- Early rubber was made from latex of rubber trees, rubber grass and other materials made of flexible, insulating, impermeable and air.

- Q: What is the composition of the vulcanizing agent for silica gel?

- Any material that can undergo vulcanization or cross linking with rubber is collectively referred to as a vulcanizing agent, also known as a crosslinker.Many kinds of curing agents, and growing, curing agent has been used with sulfur, selenium, tellurium, sulfur compounds, metal oxides, peroxides, resin, quinone and amine etc..

- Q: What does rubber mean?

- Rubber is derived from latex of rubber trees, rubber plants, etc. it is made of elastic, insulating, impermeable and air.

Send your message to us

China Manufacturer PVC Food Conveyor Belt,OEM,Food Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords