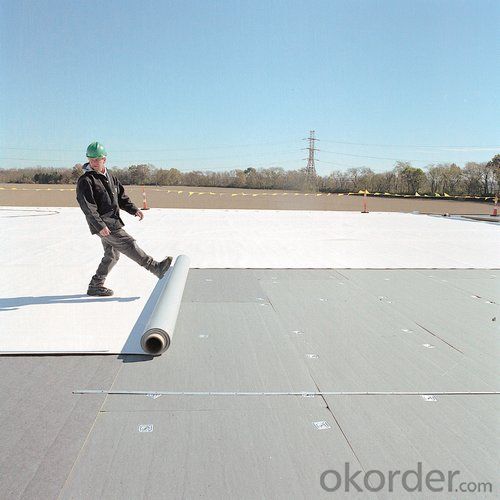

PVC High Polymer Waterproofing Membrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction for PVC Waterproofing Membrane

The P series waterproofing membrane is a heat-weldable membrane produced with an integral polyester reinforcement for high strength,for use in a Magical Stone's solution system. Its excellent performance of resistance to plasticizer extraction and migration, extend the product's life and more friendly to environment.

2.Technical data of PVC Membrane

No. | Item | Index | ||||||

H | L | P | G | GL | ||||

1 | resin thickness over the fabric mm,≥ | — | 0.4 | |||||

2 | tensile strength | max tension (N/CM),≥ | — | 120 | 250 | 120 | ||

tensile strength/Mpa,≥ | 10 | — | — | 10 | — | |||

elongation at max tension/%,≥ | — | — | 15 | — | — | |||

break elongation/%,≥ | 200 | 150 | — | 200 | 100 | |||

3 | thermal size change/%,≤ | 2 | 1 | 0.5 | 0.1 | 0.1 | ||

4 | low temperature flexibility/℃ | —25 no crack | ||||||

5 | impermeability | 0.3MPa,2h impermeable | ||||||

6 | anti-impact | 0.5kg.impermeable | ||||||

7 | static load | 20kg impermeable | ||||||

8 | cut strength/(N/mm),≥ | |||||||

joint peeling strength/(N/mm),≥ | 4 | 3 | ||||||

9 | vertical tearing strength/(N/mm),≥ | 50 | — | — | 50 | — | ||

10 | trapezoid tearing strength/(N/mm),≥ | 150 | 250 | 220 | ||||

11 | water absorption(70℃,160h)% | after saturation≤ | 4 | |||||

after dry≤ | —0.4 | |||||||

12 | heating aging | hour/h | 672 | |||||

appearance | no bubble,crack,seperation | |||||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

13 | anti chemical property | appearance | no bubble,crack,seperation | |||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

14 | artificial | hour/h | 1500 | |||||

appearance | no bubble,crack,seperation | |||||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

3.Characteristic of PVC Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

3.Applicable scope of PVC Membrane

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

4. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes resistant to freeze-thaw cycles?

- Yes, waterproofing membranes are generally resistant to freeze-thaw cycles. These membranes are designed to withstand extreme weather conditions, including freezing temperatures and the subsequent thawing process. The materials used in waterproofing membranes are often chosen for their durability and ability to expand and contract without compromising their waterproofing properties. This resistance to freeze-thaw cycles ensures that the membranes remain intact and effective in preventing water penetration, even in areas where temperature fluctuations occur frequently.

- Q: Can a waterproofing membrane be used on precast chrome surfaces?

- Indeed, precast chrome surfaces can be safeguarded by employing a waterproofing membrane. These membranes are frequently utilized to shield surfaces against water harm and hinder moisture from infiltrating the structure. In addition, the application of a waterproofing membrane on precast chrome surfaces can prove advantageous by guaranteeing their endurance and robustness. By creating a barrier between the surface and any potential water infiltration, the membrane effectively safeguards the precast chrome, sustaining its aesthetic appeal and functionality. It is crucial to select a waterproofing membrane that is harmonious with chrome surfaces and adhere to the manufacturer's guidelines for accurate application.

- Q: Can a waterproofing membrane be used for tunnels?

- Yes, a waterproofing membrane can be used for tunnels. Tunnels are often exposed to water infiltration due to their underground nature, making waterproofing crucial to prevent water damage and ensure structural integrity. Waterproofing membranes, which are specially designed to provide a barrier against water penetration, can be applied to the tunnel walls, floors, and ceilings to create a waterproof seal. These membranes are typically made of materials such as bitumen, EPDM, PVC, or polyurethane, which are highly resistant to water and can withstand the constant exposure to moisture in tunnels. Additionally, waterproofing membranes can also provide protection against other potential sources of water ingress, such as groundwater or heavy rainfall. Overall, the use of a waterproofing membrane in tunnels is a reliable and effective method to maintain a dry and safe environment within the tunnel structure.

- Q: Can a waterproofing membrane be used in historical or heritage buildings?

- Yes, a waterproofing membrane can be used in historical or heritage buildings. However, it should be done with caution and expertise to ensure that the membrane does not compromise the historical integrity or aesthetic value of the building. The selection and installation of the membrane should be carried out by professionals who understand the specific requirements and challenges associated with preserving the architectural significance of such buildings.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Absolutely, government or municipal projects can most certainly utilize a waterproofing membrane. It is, in fact, a vital element frequently employed in the construction or refurbishment of diverse infrastructure projects like roads, bridges, tunnels, and buildings. The purpose of waterproofing membranes is to thwart water infiltration, which may inflict harm upon the structure and undermine its stability. By incorporating a waterproofing membrane, government and municipal projects can guarantee the endurance and robustness of their infrastructure, thereby diminishing the necessity for costly repairs or replacements in the future. Furthermore, these membranes also contribute to energy efficiency by preventing moisture intrusion, thereby reducing the potential for mold growth and enhancing insulation properties. All in all, it is highly recommended to integrate a waterproofing membrane in government or municipal projects to elevate the lifespan and functionality of the infrastructure.

- Q: Can a waterproofing membrane be used on precast steel surfaces?

- Yes, a waterproofing membrane can be used on precast steel surfaces. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they can be applied to a variety of surfaces, including precast steel. The membrane acts as a waterproof layer, preventing water from penetrating the surface and causing damage. It is important to ensure that the surface is properly prepared and cleaned before applying the membrane to ensure proper adhesion and effectiveness. Additionally, it is recommended to consult with a professional waterproofing contractor to determine the best type of membrane and application method for the specific precast steel surface.

- Q: Can a waterproofing membrane be used on tile surfaces?

- Yes, a waterproofing membrane can be used on tile surfaces. It helps to provide an additional layer of protection against water damage and helps to prevent water penetration through the tile surface and grout lines.

- Q: Can a waterproofing membrane be used in swimming pools or water features?

- Swimming pools or water features can benefit from the use of a waterproofing membrane. This type of membrane is commonly employed in these scenarios to establish a barrier between the water and the surrounding structure. By doing so, it prevents any water leakage and structural damage, ultimately ensuring the swimming pool or water feature's longevity and durability. Typically, the membrane is applied to the structure's surface and can be composed of various materials like rubber, PVC, or bitumen. It is imperative to select a membrane specifically designed for underwater applications to guarantee its effectiveness in providing a watertight seal. Furthermore, proper installation and regular maintenance of the waterproofing membrane are vital to uphold its long-term performance.

- Q: Are waterproofing membranes breathable?

- No, waterproofing membranes are not typically breathable. They are designed to prevent water penetration, but this also means that air cannot easily pass through them.

- Q: Can a waterproofing membrane be used for wastewater facilities?

- Yes, a waterproofing membrane can be used for wastewater facilities. Waterproofing membranes are commonly used in wastewater facilities to prevent water leakage and seepage. They provide an effective barrier against water infiltration and protect the structure from water damage. Additionally, these membranes are resistant to chemicals and can withstand harsh environmental conditions often found in wastewater facilities.

Send your message to us

PVC High Polymer Waterproofing Membrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords