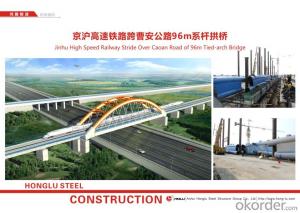

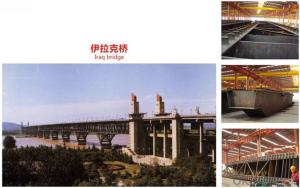

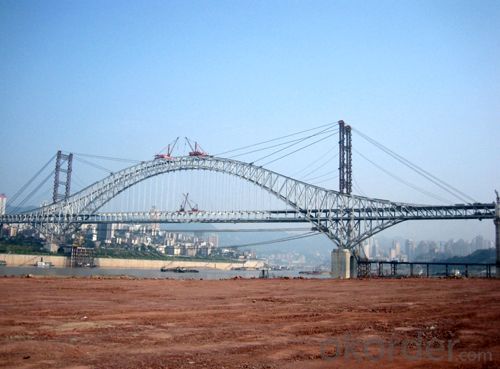

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

| Model Number | B |

| Material | Metal |

| Drawing for design | According to your requirement.We can quote according to your drawing. |

| Surface Treatment | Hot galvanized,painted,powder coated |

Packing Details

| a)Steel strip. |

| b)According to the customers' requirement |

Payments and Shipping Terms

| MOQ | 25 Ton |

| Supply Ability | 100 ton/Month |

| Payment Term | a)L/C b)T/T |

| FOB Shanghai Price | USD1000-1200/Ton |

Check Below for more imformation on placing an order

| 1. Inquiry-Professional quotation. |

| 2. Confirm the price, lead time, payment term etc. |

| 3. Our sales send the Proforma Invoice. |

| 4.Customer make the payment for deposit and send us Bank receipt. |

5.We will arrange the production & inform the estimated time. |

6. Middle Production:send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

7. End Production:Mass production products photos will send to you for approval. You can also arrange the third party Inspection. |

8. Clients make payment for balance and we Ship the goods .Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients. |

9. Order can be say “finish” when you receive the goods and satisfy with them . |

10. Feedback to us about Quality , Service, Market Feedback & Suggestion. And we will do better. |

- Q: How are steel structures designed to withstand seismic forces?

- Steel structures are designed to withstand seismic forces through a combination of factors. First, the use of high-strength steel materials with excellent ductility allows the structure to absorb and dissipate the seismic energy effectively. Secondly, various structural elements like braces, shear walls, and moment frames are incorporated into the design to enhance the building's stiffness and resistance to lateral forces. Additionally, engineers consider the building's weight distribution, foundation design, and overall structural configuration to ensure stability during seismic events. These measures collectively help steel structures to effectively resist seismic forces and minimize damage.

- Q: What are the advantages of using steel structures in the automotive industry?

- There are several advantages of using steel structures in the automotive industry. Firstly, steel is known for its high tensile strength, which makes it a reliable and sturdy material for constructing car frames and structural components. This strength enhances the safety of vehicles in case of accidents or collisions. Secondly, steel is a highly durable material that can withstand harsh weather conditions, corrosion, and wear and tear. This durability ensures that the structure of the vehicle remains intact over a longer period, reducing maintenance and repair costs. Additionally, steel is readily available and cost-effective compared to other materials used in the automotive industry. This makes it a preferred choice for mass production and helps in keeping the overall manufacturing costs down. Moreover, steel is easily recyclable, making it an environmentally friendly option. The automotive industry is increasingly focusing on sustainability, and the use of steel structures aids in reducing the carbon footprint by promoting the recycling and reusing of materials. Overall, the advantages of using steel structures in the automotive industry include high strength, durability, cost-effectiveness, and environmental sustainability.

- Q: How are steel structures designed for different mezzanine levels?

- Steel structures for different mezzanine levels are typically designed based on the specific requirements of the space and the intended use of the mezzanine. Factors such as the load capacity, span length, and height clearance are taken into consideration during the design process. Structural engineers use computer-aided design software, along with relevant building codes and regulations, to create robust and efficient steel structures that can safely support the desired mezzanine levels.

- Q: How do steel structures provide resistance against seismic-induced soil liquefaction?

- There are several mechanisms through which steel structures can resist seismic-induced soil liquefaction. Firstly, the strength and stiffness of steel make it suitable for withstanding the dynamic forces of an earthquake. Steel structures are designed to have enough strength and flexibility to resist ground shaking and remain stable during seismic events, preventing collapse even in liquefied soil conditions. Secondly, steel structures can be designed to be flexible, which helps dissipate seismic energy and reduce forces transmitted to the foundation. In liquefiable soils, the ground experiences significant lateral displacements during an earthquake. The flexibility of steel structures allows them to deform and absorb these displacements, minimizing the potential for soil liquefaction. Furthermore, the lightweight nature of steel structures contributes to their ability to resist seismic-induced soil liquefaction. The lower weight of steel reduces the load on the foundation, preventing excessive settlement and movement of the underlying soil. This is especially advantageous in areas with loose or liquefiable soils, as it reduces the risk of soil liquefaction and subsequent structural damage. Moreover, steel structures can be constructed with deep foundations that extend into stable soil layers, bypassing the liquefiable soils. By reaching below the liquefiable layer, steel structures can transfer seismic loads to more stable ground, minimizing the risk of soil liquefaction. Lastly, steel structures can incorporate various techniques to mitigate soil liquefaction effects. These include ground improvement methods like compaction, soil densification, and the installation of reinforcement elements such as stone columns or deep soil mixing. These techniques strengthen the soil and increase its resistance to liquefaction, providing added protection to the steel structure. In conclusion, steel structures resist seismic-induced soil liquefaction through their strength, flexibility, lightweight nature, deep foundations, and the use of ground improvement techniques. By withstanding dynamic forces and minimizing the effects of soil liquefaction, steel structures contribute to the overall seismic resilience of buildings and infrastructure.

- Q: How do steel structures compare to concrete structures in terms of durability?

- Steel structures and concrete structures have different characteristics when it comes to durability. While both materials are known for their strength, steel structures are generally more resistant to corrosion and can withstand extreme weather conditions better than concrete structures. However, concrete structures have a longer lifespan and are better at resisting fire and natural disasters like earthquakes. Ultimately, the durability of a structure depends on various factors such as design, maintenance, and the environment it is exposed to.

- Q: How are steel structures designed for soil-structure interaction?

- To ensure stability and integrity, careful consideration is given to soil-structure interaction during the design of steel structures. This interaction refers to the way the steel structure and underlying soil interact, which greatly affects the structure's overall behavior and performance. In the design process of steel structures, several factors related to soil-structure interaction are taken into account. One important factor is the geotechnical properties of the soil, including its strength, stiffness, and settlement characteristics. These properties are determined through soil testing and analysis, providing insight into how the soil will interact with the steel structure. The design process also considers the various loadings on the steel structure, such as dead loads, live loads, wind loads, and seismic loads. These loadings can cause stresses and deformations in the structure, and the soil-structure interaction is crucial in distributing these loads to the underlying soil. The design engineer must ensure that the steel structure can safely transfer and distribute these loads to the soil, without causing excessive settlement or deformation. Different methods and approaches are used to design steel structures considering soil-structure interaction. One common approach is the use of foundation systems, such as footings or piles, to support the steel structure. The size, shape, and depth of these foundations are determined based on the geotechnical properties of the soil and the loads on the structure. These foundations provide a stable base for the steel structure and help distribute the loads to the soil effectively and safely. Advanced techniques, like finite element analysis, are often employed to analyze and model the behavior of soil-structure interaction. These techniques allow engineers to simulate and study the behavior of the steel structure and underlying soil under different loading conditions. By analyzing stress and deformation patterns in the structure and soil, engineers can optimize the design and ensure the structure is safe and reliable. Overall, designing steel structures to consider soil-structure interaction is a complex process that requires a thorough understanding of the geotechnical properties of the soil and the behavior of the steel structure. By considering loadings, foundation systems, and using advanced analysis techniques, engineers can effectively design steel structures capable of withstanding the effects of soil-structure interaction.

- Q: How are steel structures designed for different crane systems?

- Steel structures are designed for different crane systems by considering factors such as the load capacity, span, and type of crane being used. The design process involves analyzing the structural requirements and dynamics, ensuring that the steel structure can withstand the loads imposed by the crane system. Additionally, factors like the height and clearances required by the crane are taken into account to optimize the design for efficient and safe operation.

- Q: What are the guidelines for the maintenance and inspection of steel structures?

- The guidelines for the maintenance and inspection of steel structures typically include regular visual inspections to identify any signs of corrosion, cracking, or other structural issues. It is important to follow manufacturer recommendations for cleaning and maintenance, including regular washing and removal of any debris that can contribute to corrosion. Additionally, periodic structural inspections by certified professionals are crucial to ensure the integrity and safety of the steel structure. Regular maintenance and inspections help to identify and address any potential issues early on, preventing costly repairs or structural failures.

- Q: What are the considerations for designing steel structures for cold climates?

- When designing steel structures for cold climates, several considerations need to be taken into account. Firstly, the structural elements should be designed to withstand the low temperatures, as steel can become brittle and lose its strength in cold environments. This may require using steel grades that are suitable for low-temperature applications or providing additional insulation to prevent rapid heat loss. Another important consideration is the potential for snow and ice accumulation on the structure. The design should incorporate proper support and load calculations to account for the added weight and ensure the structure can withstand these loads. Additionally, snow guards or sloped roofs may be necessary to prevent sudden snow or ice sliding, which can pose a safety risk. Thermal bridging is another concern in cold climates. Steel has high thermal conductivity, which can result in heat loss and energy inefficiency. Therefore, the design should include thermal breaks or insulation to minimize thermal bridging and maintain a comfortable indoor environment. Lastly, corrosion protection is crucial in cold climates where deicing salts or moisture can accelerate the corrosion process. Proper coatings or galvanization should be applied to the steel to enhance its durability and prevent premature deterioration. Overall, designing steel structures for cold climates requires considering factors such as low-temperature effects on steel, snow and ice loads, thermal bridging, and corrosion protection to ensure the longevity, safety, and energy efficiency of the structure.

- Q: What are the considerations for designing steel structures in areas with high humidity?

- Careful consideration is necessary when designing steel structures in areas with high humidity to prevent corrosion and ensure the longevity and safety of the structure. Some key factors to consider include: 1. Selection of materials: It is crucial to choose the right type of steel and protective coatings. Often, stainless steel or weathering steel, which form a protective oxide layer, are preferred. Another effective option is to galvanize the steel or apply corrosion-resistant coatings. 2. Ventilation and drainage: Incorporating proper ventilation and drainage systems is important to prevent moisture accumulation. This involves designing for natural airflow and providing sufficient drainage to minimize steel exposure to standing water or excessive moisture. 3. Control of condensation: Condensation can occur when warm, moist air comes into contact with colder surfaces. To minimize condensation on steel surfaces, it is important to use proper insulation and vapor barriers. Additionally, designing for thermal breaks and providing adequate insulation can help reduce temperature differences and mitigate potential condensation issues. 4. Maintenance and inspection: Regular maintenance and inspections are essential to identify and address any signs of corrosion or damage. It is necessary to periodically clean, paint, and reapply protective coatings to maintain the integrity of the steel structure. 5. Humidity control: Controlling humidity levels within the structure may be necessary in some cases. This can be achieved by using dehumidifiers or proper HVAC systems to maintain relative humidity levels within an acceptable range. 6. Consideration of environmental factors: High humidity areas often come with other environmental factors such as saltwater exposure, coastal environments, or chemical pollutants. Designers should consider these factors to select appropriate materials and protective measures specific to the local conditions. 7. Structural design: The structural design should take into account the potential effects of high humidity, such as increased corrosion rates and reduced load-bearing capacity over time. It is important to follow appropriate safety factors and design codes to ensure the structural integrity of the steel elements. By considering these factors, designers can minimize the risk of corrosion and ensure the durability and safety of steel structures in areas with high humidity.

Send your message to us

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords