Prime Steel Angle Bar with Low Price_Steel Angle Price_Angle Bar Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prime Steel Angle Bar with Low Price_Steel Angle Price_Angle Bar Steel

Detailed Informaion

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

Description | prime steel angle bar with low price / steel angle price / angle bar steel |

Thickness | 3-24 mm |

Length | 6m,9m,12m or as required |

Standard | GB/T 9787-2008,GB/T 706-2008, JIS G3101,ASTM |

Material | Q195, Q215, Q235, Q345, SS400, A36 |

Surface treatment | Galvanized |

Equal Angle | Size: 20-200mm |

| Thickness: 3.0-24mm |

| Weight: 0.597-71.168kg/m |

| Type: 2.5*1.6-20*12.5# |

| Size:25*16-200*125mm |

Unequal | Long Side: 25-200mm |

Angle | Short Side: 16-125mm |

| Thickness: 3.0-18mm |

| Weight: 1.687-43.588kg/m |

| widely used in a variety of architectural and |

| engineering structures, such as |

Application | a.) beams, bridges, ship; |

| b.) transmission tower, reaction tower; |

| c.) lifting transportation machinery; |

| d.) industrial furnace; |

| e.)container frame, warehouse goods shelves, etc |

Chemical Composition | C<0.22% Mn: 0.30—0.65% P<0.060% S<0.060% |

Payment | TT ,L/C |

Packing | Standard seaworthy bundle packing or as required |

Delivery time | About 10-30 days, mainly according to your quantity |

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

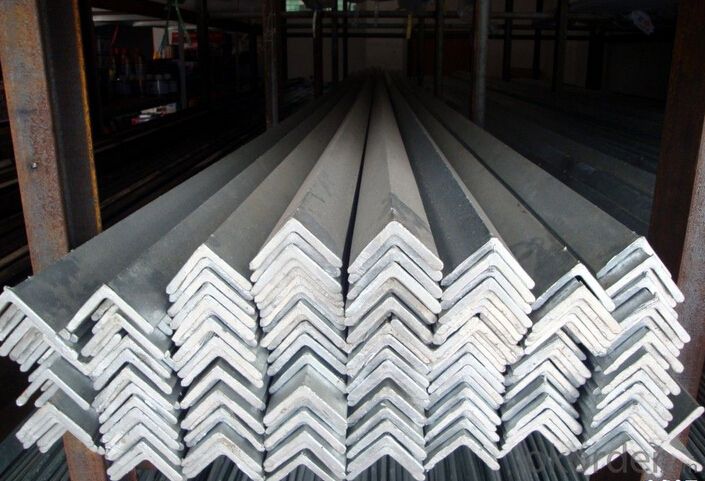

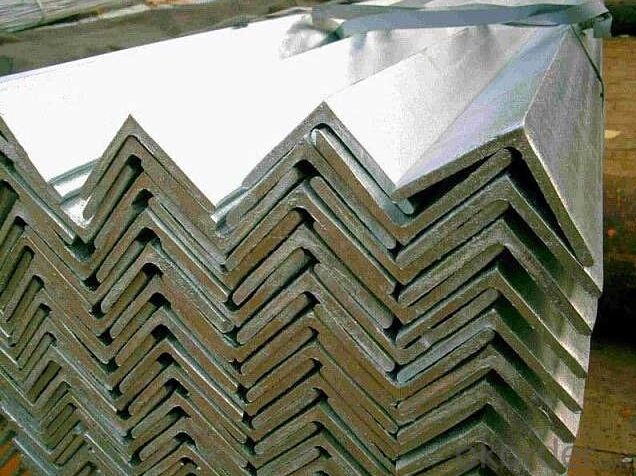

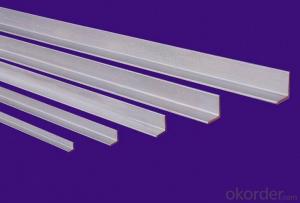

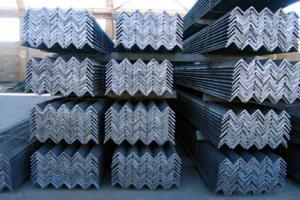

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the applications of special steel in the agriculture supply chain?

- Special steel has several applications in the agriculture supply chain. It is commonly used in the manufacturing of farm equipment and machinery such as tractors, plows, and harvesters. Special steel's high strength and durability make it ideal for these heavy-duty applications, ensuring that the equipment can withstand the demanding conditions of the agricultural sector. Additionally, special steel is also used in the production of storage tanks and silos, providing a robust and reliable solution for storing grains, fertilizers, and other agricultural products.

- Q: What are the different quality control measures for special steel production?

- There are several quality control measures for special steel production, including thorough material inspections, precise chemical composition analysis, stringent dimensional and shape control, non-destructive testing methods such as ultrasonic and magnetic particle inspections, and rigorous mechanical property evaluations. Additionally, heat treatment processes and surface treatments are closely monitored to ensure the desired properties and surface finish of the special steel. Continuous monitoring and quality checks are essential throughout the production process to maintain the highest standards and meet customer requirements.

- Q: What are the different methods of surface honing for special steel?

- Surface honing for special steel can be achieved through various methods, each with its own benefits and uses. Among the commonly employed techniques are: 1. Manual Honing: This approach entails the utilization of handheld honing tools, such as stones, sticks, or abrasive pads, to manually remove material from the steel's surface. Manual honing permits meticulous control and is often suitable for smaller or intricate components. 2. Machine Honing: Machine honing involves the use of specialized honing machines that automate the honing process. These machines typically feature rotating honing stones or abrasive belts, which eliminate material from the steel's surface. Machine honing is favored for larger or complex parts, as it ensures consistent and high-quality outcomes. 3. Diamond Honing: Diamond honing relies on diamond abrasives to eradicate material from the special steel's surface. Given that diamond is one of the hardest substances known, it is exceptionally effective for honing steel. This method is commonly employed in high-precision applications or instances where an exceedingly smooth surface finish is required. 4. Superfinishing: Superfinishing is a specialized honing process that achieves extremely fine surface finishes on special steel. It combines honing stones and abrasive pastes to remove minuscule amounts of material from the surface. Superfinishing is typically utilized in critical applications where surface roughness and dimensional accuracy are of utmost importance. 5. Lapping: Lapping is a honing method that employs a combination of abrasive particles and a rotating or vibrating tool to eliminate material from the steel's surface. It is particularly suitable for parts necessitating a very flat or parallel surface, such as bearings or sealing surfaces. 6. Electrochemical Honing: Electrochemical honing is a specialized process that employs an electric current to remove material from the special steel's surface. It is often employed for intricate or hard-to-reach surfaces, as it effectively eliminates material from areas inaccessible to other honing methods. To sum up, the various methods of surface honing for special steel encompass manual honing, machine honing, diamond honing, superfinishing, lapping, and electrochemical honing. Each method offers distinct advantages and applications, enabling precise control and the attainment of desired surface finishes and dimensional accuracy for special steel components.

- Q: How is special steel used in the aerospace manufacturing process?

- Special steel is used in the aerospace manufacturing process for various applications, such as producing critical components like landing gear, turbine blades, and engine parts. The high strength, durability, and resistance to corrosion make special steel an ideal material for these aerospace components, ensuring the safety, reliability, and performance of the aircraft.

- Q: How does special steel contribute to the automotive aftermarket industry?

- The automotive aftermarket industry greatly benefits from the use of special steel, as it offers various advantages that enhance the performance, durability, and safety of vehicles. To begin with, special steel is renowned for its exceptional strength and durability. This characteristic allows manufacturers and suppliers to create high-performance components and parts that can withstand extreme conditions and heavy usage. Engine parts, suspension systems, and chassis components all benefit from the superior strength of special steel, ensuring their longevity and reliability. Furthermore, special steel provides excellent corrosion resistance, which is crucial for automotive components exposed to different weather conditions and road environments. By utilizing corrosion-resistant steel, suppliers can produce parts that are less susceptible to rust and degradation, ultimately prolonging the lifespan of vehicles and reducing the need for frequent replacements. Additionally, special steel enables the production of lightweight components without compromising on strength. As the demand for fuel efficiency and reduced emissions continues to grow, lightweight materials are highly sought after in the automotive industry. By utilizing special steel, suppliers can create lightweight parts that contribute to improved fuel economy and overall vehicle performance. Moreover, the versatility of special steel allows for the development of complex and intricate components, which supports advancements in vehicle technology. From precision-engineered gears and shafts to specialized parts for electric vehicles, special steel can be tailored to meet specific automotive requirements, driving continuous innovation within the industry. Finally, special steel offers cost-effectiveness in the automotive aftermarket industry. While the initial cost of special steel may be higher than conventional steel, its durability and longevity result in reduced maintenance and replacement costs over time. This benefit is particularly significant for suppliers and vehicle owners, as it helps minimize expenses and ensures a higher return on investment. In conclusion, special steel plays a crucial role in the automotive aftermarket industry by providing strength, durability, corrosion resistance, lightweight properties, versatility, and cost-effectiveness. These qualities contribute to the overall performance, safety, and longevity of vehicles, making special steel an essential material in the development of high-quality aftermarket components and parts.

- Q: What are the different methods of machining special steel?

- There are several different methods of machining special steel, each with its own advantages and applications. Some of the most common methods include: 1. Turning: Turning is a machining process that involves rotating a workpiece while a cutting tool removes material from the surface. This method is typically used to create cylindrical shapes and can produce high-quality finishes. 2. Milling: Milling is a versatile machining method that uses rotary cutters to remove material from a workpiece. It can be used to create complex shapes and contours, and is often employed in the production of special steel components. 3. Drilling: Drilling is a machining process that involves creating holes in a workpiece using a rotating cutting tool. It can be used to create both through holes and blind holes in special steel, and is commonly used in various industries. 4. Grinding: Grinding is a precision machining method that uses an abrasive wheel to remove material from a workpiece's surface. It is often used to achieve tight tolerances and smooth finishes on special steel components. 5. Broaching: Broaching is a machining process that uses a sharp cutting tool with multiple teeth to remove material in a series of linear cuts. It is commonly used to create keyways, splines, and other intricate shapes in special steel. 6. Electrical Discharge Machining (EDM): EDM is a non-traditional machining method that uses electrical discharges to remove material from a workpiece. It is particularly useful for machining special steel with complex shapes or for creating small features. 7. Laser Cutting: Laser cutting utilizes a high-powered laser to cut through special steel with extreme precision. It is commonly used for intricate designs and can produce smooth edges without the need for subsequent processing. Each of these methods has its own advantages and limitations, and the choice of machining method depends on factors such as the desired outcome, the complexity of the part, and the properties of the special steel being machined.

- Q: What is the role of carbon in special steel?

- Carbon plays a crucial role in special steel as it significantly influences its properties and performance. Special steel refers to a category of steel that is specifically engineered to exhibit exceptional characteristics, such as high strength, hardness, wear resistance, or corrosion resistance. Carbon is one of the main alloying elements in special steel, and its content determines many of these desired properties. Firstly, carbon is responsible for increasing the strength and hardness of special steel. As carbon is added to the iron matrix, it forms iron carbides, which are extremely hard and provide structural integrity to the steel. The higher the carbon content, the greater the hardness and strength of the steel. This makes special steel suitable for applications requiring high toughness, durability, and resistance to deformation, such as in the manufacturing of tools, dies, and industrial machinery components. Secondly, carbon contributes to the wear resistance of special steel. The presence of carbon enhances the steel's ability to resist abrasion and withstand extreme conditions. This is particularly important in industries like mining, construction, and oil and gas, where components are subjected to intense wear and friction. Furthermore, carbon also plays a crucial role in determining the machinability and weldability of special steel. The carbon content affects the steel's response to heat treatment, making it easier or harder to machine or weld. The right balance of carbon content is essential to ensure that special steel can be easily worked on and fabricated into complex shapes without compromising its properties. Lastly, carbon influences the corrosion resistance of special steel. While steel is generally prone to corrosion, the addition of certain amounts of carbon can enhance its resistance to rusting and other forms of corrosion. This is particularly important in applications where the steel is exposed to harsh environments, such as marine or chemical industries. In summary, carbon plays a vital role in special steel by increasing its strength, hardness, wear resistance, machinability, weldability, and corrosion resistance. The precise amount of carbon added to the steel is carefully controlled to achieve the desired properties for specific applications, making special steel a highly versatile and sought-after material in various industries.

- Q: What are the properties and characteristics of special steel?

- Special steel, also known as alloy steel, has several unique properties and characteristics. Firstly, it possesses exceptional strength, making it highly resistant to deformation and wear. This strength is often achieved through the addition of various elements such as chromium, nickel, and molybdenum, which enhance its toughness and hardness. Additionally, special steel exhibits excellent corrosion resistance, allowing it to withstand harsh environments without succumbing to rust or degradation. It also demonstrates good heat resistance, making it suitable for applications involving high temperatures. Moreover, special steel can be easily machined and welded, offering versatility in manufacturing processes. Overall, the properties and characteristics of special steel make it a preferred material for a wide range of industries, including aerospace, automotive, and construction.

- Q: How does special steel comply with international standards?

- Special steel, specifically designed and manufactured to possess exceptional properties and performance, undergoes a rigorous process to ensure its quality and conformity to established norms. To begin with, adherence to international standards in the production of special steel is achieved through the meticulous selection of raw materials. The composition and quality of these materials are carefully controlled and tested to meet the specifications outlined by international standards organizations. This guarantees that the resulting special steel is of the desired quality and possesses the necessary mechanical properties. In addition, standardized production processes are followed by special steel manufacturers. These processes are designed in accordance with international guidelines and standards to ensure consistency and traceability. Through the use of advanced technologies and quality control measures, manufacturers can monitor and control every stage of production, from melting and casting to rolling and heat treatment. This guarantees that the final product meets the required standards in terms of chemical composition, mechanical properties, and dimensional tolerances. Moreover, stringent testing and inspection procedures are conducted to validate the compliance of special steel with international standards. Certified laboratories and independent third-party agencies perform various destructive and non-destructive testing methods, such as ultrasonic testing, hardness testing, and microstructure analysis. These tests ensure unbiased and accurate results. Furthermore, special steel manufacturers often have their production processes and quality management systems audited and certified by recognized bodies, like ISO, to demonstrate their commitment to compliance with international standards. It is also important to note that special steel manufacturers actively participate in international standardization committees, such as ASTM International and ISO. By engaging in these committees, they contribute to the development and revision of international standards, ensuring that their products remain up to date and aligned with the latest industry requirements. In conclusion, special steel complies with international standards through careful raw material selection, adherence to standardized production processes, rigorous testing and inspection, and active participation in international standardization committees. By following these measures, special steel manufacturers demonstrate their dedication to producing high-quality products that meet the strict requirements of international standards.

- Q: How is corrosion-resistant stainless steel used in the production of marine equipment?

- Corrosion-resistant stainless steel is extensively used in the production of marine equipment due to its ability to withstand harsh marine environments. It is commonly used in the construction of ship hulls, propellers, valves, pumps, and other critical components. The stainless steel's resistance to corrosion helps prevent damage caused by saltwater, which can significantly extend the lifespan of the equipment and ensure its reliability and safety at sea.

Send your message to us

Prime Steel Angle Bar with Low Price_Steel Angle Price_Angle Bar Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords