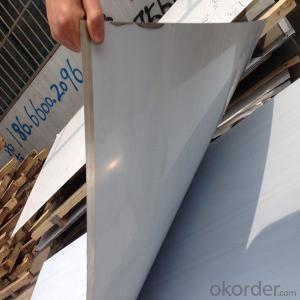

1mm ASTM Stainless Steel Sheet price ss 316

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product name | 1mm ASTM stainless steel sheet price ss 316 | ||

Production Standard | ASTM A240,GB,EN,DIN,JIS,BS | ||

Material | 201,202,304,316,304L,316L,305,309S,310S,316Ti,317,321,317L,347, 316N,316LN,410,420,430,2205 etc | ||

Shape | Sheet, coil | ||

Size | Thickness (mm) | Width (mm) | Length (mm) |

0.2~120 | 1000,1219,2000 2440,etc | 2000,2400,1500,3000, 6000 etc | |

Processing | Hot rolled , cold rolled | ||

Surface Treatment | Polishing, 2B,BA,NO.1,NO.4,8K ,Brushed, Mirror finish, embossed finish, hair line finished | ||

Packing | Standard export packing Plastic bag or waterproof paper Wooden case (custom suffocating free) Pallet | ||

Property | Higher ductility, toughness and mechanical strength ,Corrosion resistance , Acid resistance | ||

Application | Stainless steel plate applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry,boiler heat exchanger, machinery and hardware fields. Stainless steel plate can be made according to the customer’s requirements. | ||

Packaging & Shipping

1.Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

2.Shipping: Ocean transportation,land transportation or air transportation.

- Q: What are the different types of etched finishes available for stainless steel sheets?

- There are several different types of etched finishes available for stainless steel sheets, each providing a unique and distinctive appearance. Some of the most common etched finishes include: 1. Brushed Finish: This is a popular etched finish that creates a uniform and linear texture on the surface of the stainless steel sheet. It is achieved by brushing the sheet with a fine abrasive material, resulting in a smooth and satin-like appearance. 2. Bead Blasted Finish: In this etched finish, small glass or ceramic beads are blasted onto the surface of the stainless steel sheet at high pressure. This process creates a non-directional and uniform texture, giving the sheet a matte and slightly rough appearance. 3. Mirror Finish: Also known as a No. 8 finish, this etched finish creates a highly reflective and mirror-like surface on the stainless steel sheet. It is achieved through a series of grinding, buffing, and polishing processes, resulting in a flawless and shiny appearance. 4. Satin Finish: This etched finish is similar to a brushed finish but has a finer and smoother texture. It is achieved by using a finer abrasive material during the brushing process, resulting in a soft and elegant appearance. 5. Patterned Finish: This etched finish involves creating various patterns or designs on the surface of the stainless steel sheet. It can be achieved through techniques such as laser etching, chemical etching, or embossing, allowing for a wide range of creative and customizable options. These different etched finishes offer a variety of aesthetic choices for stainless steel sheets, allowing them to be used in various architectural, decorative, and industrial applications. The choice of finish depends on the desired appearance, functionality, and intended use of the stainless steel sheet.

- Q: Are stainless steel sheets suitable for roofing applications?

- Certainly, roofing applications can benefit from the use of stainless steel sheets. Stainless steel possesses qualities such as durability, corrosion resistance, and strength, rendering it an excellent choice for roofs. It exhibits remarkable tolerance to severe weather conditions like extreme temperatures, strong winds, and heavy rainfall. Moreover, stainless steel sheets possess fire-resistant properties, thereby enhancing the safety level of the roof. Furthermore, stainless steel boasts an extended lifespan, necessitating minimal maintenance and repairs. In summary, stainless steel sheets offer a dependable and enduring solution for roofing needs.

- Q: Stainless steel plate how to distinguish between good and bad, there are several thick?

- 1. identification of imported or steel ordered stainless steel materials, usually only in accordance with the import or steel quality certificate, check the steel or packaging on the mark can be.The certificate of quality is the confirmation and guarantee of the inspection result of the product by the supplier. Therefore, the certificate of quality not only indicates the name, specifications, delivery number, weight and delivery status of the materials, but also the entire inspection results of the required guarantee items.

- Q: Can stainless steel sheets be used in food processing?

- Food processing can make use of stainless steel sheets. They are commonly chosen in the food industry because of their advantageous properties. One crucial property is their resistance to corrosion, which is highly important in food processing environments where contact with water, chemicals, and food is frequent. Stainless steel sheets are also non-reactive, meaning they do not interact with food or impact its taste, thus making them a safe option for food processing equipment. Moreover, stainless steel is easy to clean and maintain, making it ideal for maintaining the high levels of hygiene required in food processing facilities. Its durability and strength ensure that it can withstand the demanding nature of food processing operations. Overall, stainless steel sheets are the preferred choice in the food industry for their suitability in food processing applications.

- Q: Can stainless steel sheets be used in outdoor applications?

- Certainly, outdoor applications can indeed make use of stainless steel sheets. Stainless steel, known for its exceptional resistance against corrosion and oxidation, proves to be a perfect option for outdoor purposes. It can endure challenging weather conditions, encompassing rainfall, snowfall, and even UV radiation, without undergoing rust or deterioration. Moreover, stainless steel exhibits impressive durability, allowing it to withstand heavy burdens and impacts, rendering it appropriate for a multitude of outdoor applications such as cladding, roofing, fencing, and decorative elements. Its attractiveness in terms of aesthetics and minimal upkeep needs further contribute to its popularity in outdoor usage.

- Q: Can stainless steel sheets be used for signage?

- Yes, stainless steel sheets can be used for signage. Stainless steel is a durable and weather-resistant material, making it suitable for both indoor and outdoor signage applications. It offers a sleek and professional look, and can be customized with various finishes and colors to meet specific design requirements.

- Q: What's the difference between stainless steel 304 2B board and Ba board?

- Cold dip - annealed, pickled - flat 2BCold dip - bright annealing - flat BA2B surface of plain cold rolled stainless steel countertops (not brushed)Surface of inner cylinder of BA ordinary mirror roller washing machineThe main difference is that annealing, 2B is annealing or pickling, the surface has a certain degree of oxidation, darker; BA bright annealing, the surface is not oxidized, brighter

- Q: Are stainless steel sheets good for high-temperature applications?

- Stainless steel sheets prove to be an exceptional choice for applications at high temperatures. With a high melting point that typically ranges from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), stainless steel becomes suitable for environments with elevated temperatures. Moreover, this type of steel displays remarkable resistance to oxidation when subjected to high temperatures, effectively preventing the formation of scales or rust that could potentially weaken the material. Additionally, stainless steel boasts good thermal conductivity, facilitating efficient heat transfer. These remarkable attributes establish stainless steel sheets as a dependable option for a diverse range of high-temperature applications, such as industrial furnaces, heat exchangers, boilers, and exhaust systems.

- Q: What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- The 8K board, also called mirror panel, is polished on the surface of stainless steel by grinding fluid through polishing equipment, so that the surface of the plate is as clear as the mirror. Uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities, decoration and other stainless steel products.

- Q: Are stainless steel sheets good for industrial exhaust systems?

- Indeed, stainless steel sheets prove to be an exceptional option for industrial exhaust systems. Renowned for its exceptional resistance to corrosion, stainless steel stands as an immensely sturdy and enduring material for exhaust systems. It exhibits the capability to endure high temperatures and withstand extreme weather conditions, hence rendering it suitable for deployment in industrial settings. Moreover, stainless steel showcases outstanding strength, enabling it to cope with the pressure and vibrations inherent in exhaust systems. Furthermore, stainless steel boasts effortless cleaning and maintenance, a crucial attribute for ensuring efficient functionality of the exhaust system. In summary, the durability, corrosion resistance, and high temperature tolerance of stainless steel sheets make them an outstanding choice for industrial exhaust systems.

Send your message to us

1mm ASTM Stainless Steel Sheet price ss 316

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords