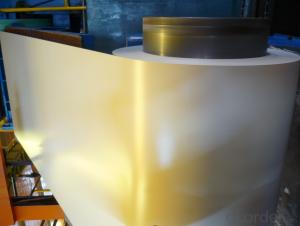

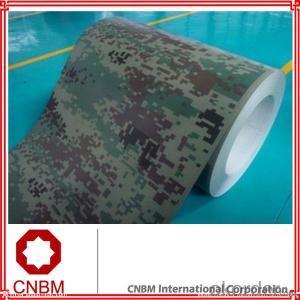

prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

prepainted steel coil

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

Hot dip galvanized steel coil

Technical Standard:JIS 3302 / ASTM A653 / EN10143/ GB/T 2518

Grade:DX51D/ S250,280,320GD,SGCC,SGHC,SGH340,SGH400,SGH440,G450,G550

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

color :RAL NO

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product- Q: How are steel coils used in the production of steel nails?

- Steel coils are used in the production of steel nails by being fed into a nail-making machine, where they are unwound and cut into the desired length. The coils provide a continuous supply of steel material, allowing for efficient and automated nail production processes.

- Q: How are steel coils used in the manufacturing of transportation equipment?

- Steel coils are used in the manufacturing of transportation equipment as they provide a strong and durable material for various components such as frames, chassis, and body panels. The coils are shaped, cut, and formed into the desired shapes and sizes to create the structural integrity required for vehicles like cars, trucks, trains, and airplanes. The high strength of steel coils ensures the safety and stability of transportation equipment, making them essential in the manufacturing process.

- Q: i mean cor ten steel( rusted)

- If the steel is true Cor Ten steel, it does not require waxing. Cor Ten is a steel designed to rust slowly over time ... then the rust acts as a natural barrier to prevent further rust. Check out the United States Steel building in downtown Pittsburgh, PA ... its nickname is The Rusty Nail.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts as they serve as the primary raw material. The coils are unwound and fed into a machine that cuts and shapes the steel into bolts of the desired size and shape. The coils provide a continuous supply of high-quality steel, ensuring the consistency and strength of the bolts produced.

- Q: Already on my team is Empoleon lvl 82Heatran lvl 74Scizor lvl 34Magnezone lvl 38What other steel types should I choose?

- Metagross would help out a lot, Excadrill id you are not doing double battles... (two of his best moves for him hit his team and are ground.. ) if you do not want to rick excadrill use a Lucario instead for hs massive damage output.

- Q: How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they serve as the primary raw material for manufacturing various components such as structural frames, panels, chassis, and other critical parts. These coils are unwound and processed through cutting, bending, and welding techniques to create the necessary shapes and sizes required for construction machinery. The high strength and durability of steel make it an ideal material for construction equipment, ensuring longevity and reliability in demanding job site conditions.

- Q: I do a lot of scrapping and would like to be able to separate stainless steel from regular steel. The magnet test doesn't always work since stainless can be magnetic, but what are some ways that I can for sure tell the difference? Or even something like a sound that they make that may help me to tell the difference.

- If you do a lot of scrapping. It is best to get XRF handheld metal analyzer. But they are quite price. Around USD 40.000 upwards! Magnet may only help you sort SUS304/316/201 from SUS430 and metal. But then there might be other alloy. Thus it is best to get XRF analyzer if you feel it is worth the price.

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps that typically include uncoiling, leveling, cutting, and shaping. After uncoiling, the steel coils are passed through a leveling machine to remove any unevenness. Then, they are cut into specific sizes and shapes using different cutting techniques such as shearing or slitting. Finally, the cut steel pieces are shaped through various processes like bending, welding, and machining to produce the desired finished products.

- Q: Is there alloys in low carbon steel or non

- Hello, okorder Hoping this can help you. :-)

- Q: Ok, so im gonna get my tragus pierced and i was wondering which is better, titanium or stainless steel. I hear like everyone uses stainless steel , but is titanium better?Thanks

- It seems like less people are allergic to titanium than surgical grade steel.

Send your message to us

prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords