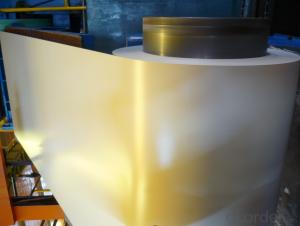

Prepainted galvanized/galvalume steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,JIS | Grade: | steel | Thickness: | 0.17-1.5mm |

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | SGCC Q195L, Q235, DX51D |

| Type: | Steel Coil | Technique: | Hot Rolled,hot dip | Surface Treatment: | Coated |

| Application: | Flange Plate | Special Use: | Steel | Width: | 600-1250mm |

| Length: | 2000-6000mm |

Specifications

1.reasonable price

2.reliable quality

3.fast shipment

4.huge production capacity

5.BV,SGS and TUV certificates

Prepainted Steel coil PPGI

Our Advantages

1. more than 10 years experiences in steel business

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

7. long mutual beneficial business cooperation

8. certificate: ISO9001

| Commodity | Prepanited steel coil |

| Grade | JIS G3302(SGCC), DX51D, EN10142, GB/T2518-2004, ASTM 653 |

| Standard | ASTM, AISI, DIN, GB |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.16-1.2mm (0.14-0.5mm is the most advantage thickness) |

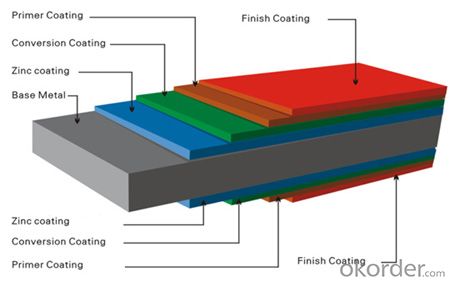

| Type of coating | Galvanized |

| Zinc / PE coating | Z60-275g/m2 ,12-20μm(top)/7-10μm(bottom) |

| Surface | RAL System as per customers request |

| ID coil | 508mm |

| Coil weight | 4-6MT |

| Package | Properly packed for ocean freight exportation |

| Application | Industrial panels, roofing and siding for painting |

| Payment terms | 30%TT in advance+70% TT or irrevocable 100%L/C at sight |

| Delivery time | 25 days after recepit of 30% TT or L/C |

PACKING

4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection

FAQ

We have organized several common questions for our clients,may help you sincerely:

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

In the purchase of product within 20-25 days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 30 days can be served.

3)Do you have necessary certificate or inspection to make sure we can import smoothly?

Syringes are CE,FDA approved. And we supplied main nations in the world.

- Q: I am wondering what the highest quality steel is used in handgun production.

- The first answer was correct. The type of steel used in most blued handguns is the highest. After that I prefer stainless. Then the Scandium framed pistols.

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on various factors such as the size, thickness, grade, and market conditions. It is best to contact a supplier or check current market prices for an accurate cost.

- Q: What are steel coils?

- Steel coils are long, flat sheets of steel that are rolled into a circular shape and wound tightly to form a coil. These coils are commonly used in various industries, including automotive, construction, and manufacturing, as they serve as a raw material for the production of various steel products such as pipes, tubing, and sheet metal.

- Q: What are the common tests performed on steel coils?

- The common tests performed on steel coils include dimensional inspection, visual inspection, tensile testing, hardness testing, bend testing, and surface quality assessment. These tests ensure the quality, strength, and integrity of the steel coils before their use in various applications such as construction, automotive, and manufacturing.

- Q: How are steel coils inspected for hardness?

- Steel coils are inspected for hardness using a non-destructive testing method called Rockwell hardness testing. This involves pressing a diamond or ball indenter into the surface of the coil and measuring the depth of the indentation. The hardness value is then determined based on the depth of the indentation, providing an accurate assessment of the coil's hardness.

- Q: How are steel coils used in the production of metal fencing?

- Steel coils are used in the production of metal fencing as they serve as the raw material for manufacturing the fence panels and posts. The steel coils are typically flattened, cut, and shaped into various components, such as wires or sheets, which are then assembled to create the final fencing product. The durability and strength of steel make it an ideal material for fencing, ensuring the fence's ability to withstand external forces while providing security and boundary demarcation.

- Q: I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- If you put steel in the freezer, allow it to cool to 32 degrees and then put it in water a transfer of heat will occur and the water will cool off. How much and how quickly, I don't know. I believe the Mythbusters did experiments on something like this. If it were economical, we woud see steel ice cubes being sold instead of ice makers.

- Q: What are the common applications of coated steel coils?

- The excellent properties and versatility of coated steel coils make them suitable for a wide range of applications in various industries. Some common uses of coated steel coils include: 1. Construction industry extensively employs coated steel coils for roofing, cladding, and wall panels. The coating ensures long-lasting structures by providing superior corrosion resistance, durability, and weatherability. 2. In the automotive industry, coated steel coils are widely used for manufacturing body panels, bumpers, and chassis parts. The coatings enhance aesthetics, protect against corrosion, and improve paint adhesion for a flawless finish. 3. Coated steel coils find utility in the production of household appliances like refrigerators, washing machines, and ovens. The coatings provide an attractive, smooth finish while protecting the steel from moisture and environmental factors. 4. Heating, Ventilation, and Air Conditioning (HVAC) systems commonly utilize coated steel coils for manufacturing ductwork, air handling units, and heat exchangers. The coatings ensure resistance against corrosion and improve system efficiency. 5. The furniture industry also makes use of coated steel coils for manufacturing cabinets, tables, and chairs. The coatings provide a decorative finish while protecting the steel from wear and tear. 6. Electrical equipment production, including switchboards, control panels, and enclosures, involves the use of coated steel coils. The coatings provide insulation and protection against electrical conductivity, ensuring durability. 7. In the packaging industry, coated steel coils are used for manufacturing cans, containers, and closures. The coatings act as a barrier against moisture and prevent contamination, ensuring the preservation and safety of packaged products. In conclusion, coated steel coils offer corrosion resistance, durability, aesthetics, and protective properties, making them suitable for various applications across industries. From construction to automotive, appliances to furniture, and even in electrical equipment and packaging, coated steel coils play a crucial role in delivering high-quality products and ensuring long-lasting performance.

- Q: What are the different types of steel coil cutting machines?

- In the market, there is a wide range of steel coil cutting machines available, each tailored to meet specific needs and requirements. Some commonly used types include: 1. Slitting Machines: These machines are utilized to cut steel coils into narrower strips. Equipped with multiple circular blades, they are capable of making precise cuts along the length of the coil, enabling the production of narrower coils or strips. 2. Cut-to-Length Machines: Designed to cut steel coils into specific lengths, these machines possess the ability to accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are robust cutting machines that can handle thicker and larger steel coils. Utilizing a rotating blade, they are suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Intended for cutting steel coils into multiple smaller blanks simultaneously, these machines have the capability to cut the coil into various shapes and sizes. This makes them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines integrate the functionalities of both slitting and cut-to-length machines, enabling the cutting of narrow strips and lengths in a single process. They offer versatility and efficiency, saving time and increasing productivity. Each type of steel coil cutting machine possesses distinct advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: I need to say how a bottle opener is made, would it be made from steel and can this be coloured? How?

- Steel can be plated(Chrome),Blackened(Black Oxide),Powder coated(color of your choose).All of this is done to prevent rust.All of these aforementioned processes can be worn off through being used.I suggest polished Stainless steel.

Send your message to us

Prepainted galvanized/galvalume steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords