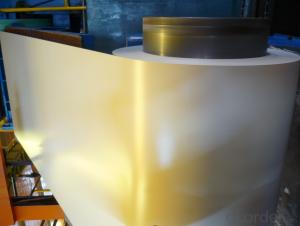

Prepainted galvanized steel coil,Prepainted galvalume steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted steel coils

1. more than 10 years experiences in steel business

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

7. long mutual beneficial business cooperation

8. certificate: ISO9001

Standard

| Commodity | Prepanited steel coil |

| Grade | JIS G3302(SGCC), DX51D, EN10142, GB/T2518-2004, ASTM 653 |

| Standard | ASTM, AISI, DIN, GB |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.16-1.2mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating | Galvanized |

| Zinc / PE coating | Z60-275g/m2 ,12-20μm(top)/7-10μm(bottom) |

| Surface | RAL System as per customers request |

| ID coil | 508mm |

| Coil weight | 4-6MT |

| Package | Properly packed for ocean freight exportation |

| Application | Industrial panels, roofing and siding for painting |

| Payment terms | 30%TT in advance+70% TT or irrevocable 100%L/C at sight |

| Delivery time | 25 days after recepit of 30% TT or L/C |

PACKING

4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection

FAQ

We have organized several common questions for our clients,may help you sincerely:

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

In the purchase of product within 20-25 days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 30 days can be served.

3)Syringes are CE,FDA approved. And we supplied main nations in the world.

- Q: How are steel coils used in the manufacturing of pipes?

- Steel coils are used in the manufacturing of pipes by being uncoiled, flattened, and then formed into a cylindrical shape through a process called pipe welding. The steel coils provide the necessary raw material for the production of pipes, ensuring strength, durability, and structural integrity.

- Q: I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- You can indeed by using the correct flux as normal soldering fluxes as used by plumbers will not work. I believe to solder steel it requires an acid flux which will corrode copper so when its done make sure its well cleaned afterwards and if possible apply a corrosion proofer afterwards ie paint or even petroleum jelly. I am curious as to why you would want to solder wire to a steel nail.

- Q: What are the different types of coil leveling machines?

- There exists a variety of coil leveling machines utilized in different industries. Some frequently encountered types are as follows: 1. Precision Roll Levelers exhibit exceptional accuracy and possess the capability to precisely level coils. Employing a series of rolls, these machines apply pressure to eliminate any distortions or imperfections in the coil. 2. Straighteners are utilized to flatten coils that have become curved or warped during the manufacturing process. Typically, they consist of a set of rollers that gradually bend the coil in the opposite direction to restore its flatness. 3. Rotary Levelers are employed to level thicker coils or those with a higher yield strength. These machines employ a series of rolls that rotate in opposite directions, exerting pressure to flatten the coil. 4. Tension Levelers are commonly used to level thin-gauge coils. They function by applying tension to the coil while passing it through a series of rollers. This process effectively removes any waviness or unevenness in the coil. 5. Stretch Levelers are specifically designed for leveling coils made of high-strength materials. These machines employ a combination of stretching and bending to eliminate any irregularities on the coil's surface. 6. Cut-to-Length Lines not only level the coil but also cut it into specific lengths according to the customer's requirements. These machines are commonly utilized in precision-demanding industries like automotive or construction. In conclusion, the choice of coil leveling machine depends on factors such as the type and thickness of the coil, desired level of accuracy, and the intended application of the leveled coil.

- Q: How are steel coils used in the production of industrial storage tanks?

- Industrial storage tanks commonly utilize steel coils due to their superior strength and durability. These coils are typically crafted from high-quality steel that is rolled into a coil shape, enabling convenient transportation and handling. During the production process, steel coils are initially uncoiled and flattened to create steel sheets. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are joined together through welding or bolting to construct the tank's body, which is designed to endure high pressure and heavy loads. The utilization of steel coils in the production of industrial storage tanks offers numerous benefits. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and resist corrosion. This is particularly vital for storage tanks containing corrosive substances or exposed to severe environments. Moreover, the flexibility of steel coils permits customization of the tank's design and size. This is especially advantageous in industries with varying storage requirements, like the oil and gas sector. Steel coils can be effortlessly cut and molded into diverse shapes and sizes, facilitating the creation of storage tanks tailored to specific storage needs. Furthermore, steel coils are easily transportable and storable, making them a cost-effective choice for industrial storage tank production. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. In conclusion, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their usage guarantees the safe storage and protection of various substances, rendering them indispensable in a wide range of industries.

- Q: How do steel coils contribute to thermal insulation in buildings?

- Steel coils do not contribute to thermal insulation in buildings. In fact, steel is a good conductor of heat, so it can actually transfer heat rather than insulate against it.

- Q: What are the different methods of coil cutting for steel coils?

- There are several methods of coil cutting for steel coils, each with its own advantages and suitability for different applications. Here are some of the common methods: 1. Slitting: Slitting is the most commonly used method for coil cutting. It involves passing the steel coil through a set of rotating circular blades that cut the coil into narrower strips. This method is suitable for producing narrow width strips with precise dimensions. 2. Shearing: Shearing is another method used for coil cutting, especially for thicker gauge coils. It involves using a straight blade to cut the coil along a straight line. Shearing is suitable for producing larger width strips and is often used for heavier gauge steel coils. 3. Laser Cutting: Laser cutting utilizes a high-powered laser beam to cut through the steel coil. This method offers a high degree of precision and can be used to cut complex shapes and patterns. Laser cutting is often used for specialized applications where accuracy and fine details are crucial. 4. Waterjet Cutting: Waterjet cutting involves using a high-pressure jet of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can be used for cutting various materials, including steel. Waterjet cutting is suitable for producing clean and precise cuts without heat-affected zones. 5. Plasma Cutting: Plasma cutting utilizes a high-temperature plasma arc to melt through the steel coil. This method is efficient and can be used for cutting thick gauges of steel. Plasma cutting can achieve high cutting speeds, making it suitable for industrial applications. 6. Guillotine Cutting: Guillotine cutting involves using a guillotine-like mechanism to cut through the steel coil. The coil is placed on a table, and a blade descends vertically to cut through it. Guillotine cutting is suitable for producing straight and accurate cuts with minimal burrs. The choice of coil cutting method depends on various factors such as the desired width and thickness of the strips, required precision, production volume, and the specific application. It is important to consider these factors and consult with experts to determine the most suitable coil cutting method for a particular steel coil.

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- The coating of zinc inhibits rust. First of all the zinc does not oxidize a readily as iron (steel). If the zinc coating gets scratched it still protects the exposed iron. When the zinc and exposed iron get wet they behave like a battery. Electrons flow from the zinc layer to the iron layer. The extra electrons in the iron layer replace any that might be lost to oxidation and help keep the iron metallic. Of course now the zinc oxidizes faster so eventually all of the metallic zinc is removed and the iron is unprotected and will rust. The fact that the zinc doesn't have to cover the steel is shown in another process. To protect the steel hulls of ocean going ships a block of zinc is attached to the bottom. The electrical circuit behaves as described above. When the zinc block has dissolved they just attach another one. If they keep this up the hull of the ship remains corrosion free. A tin coating on steel (as in a tin can) works just the opposite. When the tin is scratched the electrons flow from iron to tin so the iron rusts faster than it would have with no tin.

- Q: Which is used for what?Differences as far as style etc.???Better in your opinion and why??I'm just beginning to look at guitars i might be able to get at christmas if i'm still committed..i've been looking online.,,,,NYLON or STEEL STRINGED ACOUSTIC GUITAR????Thanks.

- Nylon stringed guitars are almost always intended for classical and flamenco guitar styles. You might see the occasional performer using one for folk, and of course Willie Nelson is famous for his nylon string sound in the country genre. The strings can be easier on a beginners fingers but you will find much less selection than with steel string guitars. Nylon has a mellower sound than steel, and good ones sound amazingly rich and full. Classical guitarists use their fingernails instead of picks to get more varied texture out of the guitar, but you can safely use a pick. Steel stringed guitars are what you are seeing and hearing most if you listen to pop, rock, country, folk, etc. There will be a much wider selection of beginner instruments to choose from. ( and some of them will be horrible!) The strings can be tougher on your fingers until you build up callouses, but that only takes a month or so. A steel string guitar will sound correct in a wider range of music, but will never sound as good at classical music as nylon. Bottom line: you can learn on either style guitar, but unless you are planning to go into classical or flamenco guitar, go with steel. In either case, don't get the cheapest one out there. It's a real case of you-get-what-you-pay-for. A cheap one will be harder to play and keep in tune.

- Q: What are the key properties of steel coils?

- The key properties of steel coils include high tensile strength, excellent durability, corrosion resistance, and the ability to be shaped and formed into different products.

Send your message to us

Prepainted galvanized steel coil,Prepainted galvalume steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords